The Complete Guide to Admix High Shear Mixer: Benefits, Applications, and Industry Insights

Producing Admix high shear mixers can bring a lot of profit as they are used in a large number of changed processes. The more they are used, the more they promise higher improvements and advancements. The aim of these mixers is to improve the products by providing size reduction, homogenizing, and emulsifying to a greater extent. In this content, we will discuss the working principles, advantages, and uses of Admix high shear mixers, as well as how they can add value to your manufacturing processes.

What is an Admix High Shear Mixer?

Admix high shear mixer is a strong device that can be found in a major part of the industrial sectors. The machine has the ability to mix, emulsify, or even homogenize the products relying on the components of the products and the manufacturing processes. A high shear force is applied on the mixture and thus the ingredients are dispersed evenly throughout the product. From food production to chemical products, the outcome is a better quality product.

How Does an Admix High Shear Mixer Work?

The most important part of an Admix high shear mixer is the mechanical forces generated when mixing takes place. The equipment generally includes a rotor and a stator which create shear forces when the rotor rotates rapidly. These forces assist in breaking down particles, in minimizing droplet sizes in emulsions, and in achieving even distribution in suspensions. This process of high shear mixing guarantees that the materials – for example, the liquid phase – are perfectly mixed which contributes to improved texture and consistency and stability of the product itself.

The Mechanics of Admix High Shear Mixer

The mechanics of mixing ingredients work through centrifuge and tangential forces. The mixing head incorporates materials that are drawn into it by the inertia of rotor running at high speeds and which has been rapidly blended to a thick paste which is forced through small openings between the rotor and stator. The velocity and pressure are so high that they cause a shearing action that splits and distributes particles in the mixture evenly.

Key Features of Admix High Shear Mixers

With indoor and outdoor field as well as the lift areas being sections where Admix high shear mixers can be employed, there are notable functions present in them:

Technical Precision

Admix mixers are specific and reliable due to the existence of rotor-stator arrangements as well that help provide adequate shear forces and ensure complete mixing.

Customization

Admix has a large variety of models that have added features depending on their application. These can include hydrogen that has been mixed with other gasses or materials increasing the efficiency and effectiveness of a certain rotor processing.

Scalability

With Admix it does not matter whether a small laboratory scale or an industry scale is required, solutions can be offered and it will fit the steps’ requirements.

Ease of Use

Admix is about minimal time loss when using Admix high shear mixers as the controls and maintenance are not complicated and do not require much time and effort to perform.

Benefits of Using Admix High Shear Mixers

For many industries possessing Admix high shear mixers proves beneficial as they have a number of benefits. Some of the most notable ones include:

Improved Product Consistency

Tackling the task of distributing all the necessary additives and promoting even multi-component systems with high order textures, high shear mixing helps to achieve the required result in an advanced material.

Increased Efficiency

Since the mixing intensity is high speed, it reduces the process time, which enables the manufacturers to improve the volume they manufacture without lowering the standard.

Energy Savings

During the dry mixing process a coarse disperser is utilized which does not use up energy reserves as much as typical mixers do and reduces production costs.

Enhanced Product Stability

No matter if the task at hand is to create an emulsion, or a dispersion or a suspension, the Admix high shear mixer guarantees a consistent and powerful performance throughout the whole production process helping stabilize the end product.

Admix High Shear Mixer in Different Industries

No one can deny the Admix high shear mixers significance in various industries but one of them stood out:

Food & Beverage

During food production, high shear mixers are normally called upon to create emulsions, dispersions and other such stable products as sauces, dressings and other dairy items with a good texture.

Where ice creams or ointments are concerned, they are referred to as homogenizing creams, ointments and suspensions in the pharmaceutical industry. This practice entails the use of such high shear mixers; reliable and robust in creating a smooth and perfectly even active ingredients distribution across products.

Cosmetics Industry

In the cosmetics industry today, such types of high shear mixers tend to have a more widespread implementation when it comes to the industrial blending of creams, lotions and gels, wherein a high shear is required.

Chemical Production

Last but not least, for chemical production, advmix high shear mixers are also employed in certain processes, paints, coatings, adhesives for example, where complicated formulations are required to be mixed at a constant ratio.

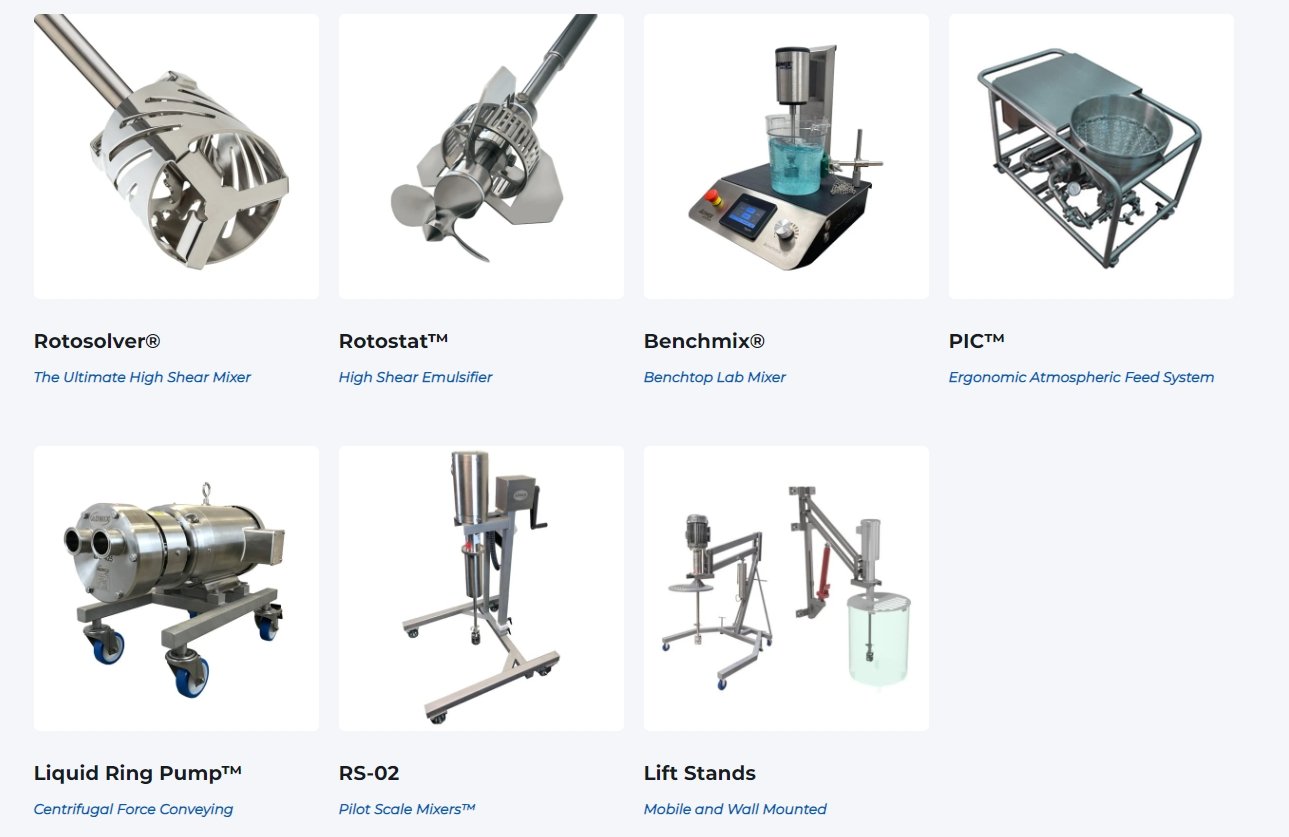

Types of Admix High Shear Mixers

Nonetheless, Admix does offer a variety of high shear mixers and each of them is designed for specific applications:

In-line High Shear Mixers

Such mixers are embedded in to the matrix production line to facilitate overheated materials continuous infusion.

Batch High Shear Mixers

Somewhat the opposite of the continuous…. These types of high shear batch mixers are onboard to mix ingredients in a batch process.

Specialized Models

With respect to its applications, Admix also offers a series of specialized mixers that focus on specific industry needs, such as tailored for high viscosity products or sensitive formulations.

Comparing Admix High Shear Mixers with Other Types of Mixers

When looking for a mixer, it is necessary to compare high shear mixers with other mixing technologies that are widely used for example:

Planetary Mixers

These interminable mixers are useful in some cases, however planetary mixers are limited by their lack of high shear forces which can efficiently reduce particle size and emulsify.

Low-speed Agitators

These mixers are suitable for blending but do not provide the intense shear forces required for emulsification or homogenization.

Homogenizers

They are however similar, homogenizers are often employed for very fine particle size reduction processes whereas applications for high shear mixers are quite wide.

Installation and Maintenance of Admix High Shear Mixers

Installation and maintenance of Admix high shear mixers are uncomplicated and dont require heavy resource spending. In order to properly adhere to the design provision:

Installation

Installer should pay close attention to the instructions provided by the manufacturer with respect to proper assembly of the machine. Take care to confirm that the mixer is well supported and all of its parts assembled correctly.

Maintenance

Cleansing and inspection of manual tools such as rotor and stator should be carried out daily to ensure performance, Regular lubrication and change of parts in the machine is also one way of increasing the longevity of equipment.

Explaining Shear Forces and Their Importance in High Shear Mixers

Most high shear mixers’ operational efficiency is dependent upon shear forces. The forces perform tasks like reducing large particles, achieving uniformity, and forming fine emulsions. The intensity of shear force is adjustable, which allows the manufacturers to manufacture mixers that work according to their products.

Common Uses of Admix High Shear Mixers

Admix high shear mixers find usage in:

Emulsifying

Mixing together oil and water based materials into stable products.

Homogenizing

Achieving uniformity in the distribution of ingredients in liquids or semi liquid products.

Suspension and Dispersion

Adding solid particles into liquids and producing them in such a manner that allows for smooth even suspension.

How To Pick An Admix High Shear Mixer For Your Process

In the event that you are picking a high shear mixer, some of the things to have in mind are the following:

Batch Size

The size of the mixer should correlate to the amount of material to be processed.

Material Properties

Ingredients such as viscosity, temperature, and chemical structures of the ingredients should be accounted for.

Application Needs

In this case, application needs include; the blender mode that will be used in emulsification or homogenization or the suspension production itself.

Energy Efficiency and Sustainability of Admix High Shear Mixers

Admix high shear mixers’ design is targeted at electrical energy sustainable practice. By lessening various processes and enhancing the quality of the end products, these mixers enable the manufacturers’ activities to be energy intensive, thereby reducing their operational cost as well as harvesting a cleaner method of production.

The Place of Admix High Shear Mixers in Product Development

In food, cosmetics, and pharmaceutical fields, much of product development starts with creating a new formula. Admix high shear mixers help manufacturers come up with more quantitative strategies on integrating ingredients, which enhances the quality of existing products and diversifies the nature of the products in the market.

Cost Issues Associated with the Purchase of An Admix High Shear Mixer

Admix high shear mixer is associated with high initial costs which may be a setback. However, as it is often the case, the benefits one stands to gain in the long run are more than the costs. More efficiency, decreased time to process, and steady and uniform products mean lots of savings in the long run.

Questions And Answers On Admix High Shear Mixers

How do an in-line Admix high shear mixer and a batch one differ?

On the one hand, in-line mixers are appropriate for continuous processes, and one the other hand, batch mixers are more suitable for reckoning specific portions.

What benefits can I expect high shear mixing to add to my products?

Through the application of high shear mixing component parts are well distributed which leads to uniform quality products.

What maintenance is necessary to achieve peak performance?

To avoid any degradation in performance, there should be regular cleaning, lubrication, and checking of rotor and stator parts.

Are Admix high shear mixers recommended for small scale production?

Yes, Admix manufactures models for small scale and mass scale production as well.

What industries gain from high shear mixing processes?

Food and beverage, pharmaceutical, cosmetic, and chemicals manufacturing are some industries that enhance their quality and quantity as a result of high shear mixers.

How should the business owners choose model for their business?

While selecting the appropriate mixer model, remember the batch size, material properties per composition, and production volume.