Best in Class Design and Performance

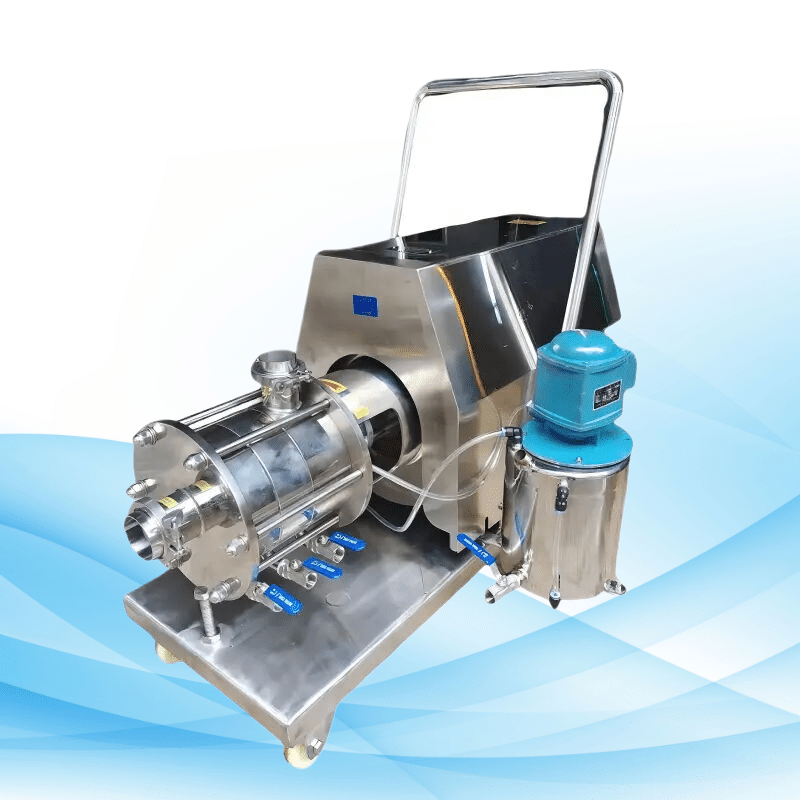

The strength and performance of the pump are fully realized with a 7.5kW motor, making it noticeably easier to work with high viscosity fluids or shear sensitive emulsions due to how reliably it provides repeatable results. It is easy to see how the pump’s multi-stage process is effective because of how effortless it is to make ultra-fine and stable emulsions.

Functional Flexibility

The Three-stage emulsifying pump’s exceptional adaptability and focus on the specific needs of the pharmaceuticals, cosmetics, food processing, chemical manufacturing, and biotechnology industries give it the pump an unparalleled ability to meet demand. If you want to easily create silky smooth creams, stable pharmaceutical ointments, perfectly homogenized sauces, or elaborate chemical emulsions, this is the pump for you.

Technical Details

Power Rating

Pertaining to the “Four Types of ILSS” item, it is possible to find options from 1.5kW to 55kW, being 7.5kW the sweet spot for efficiency and power for most industrial processes at mid scale.

Voltage Flexibility

Global electrical standards voltage options: selectable from 110V up to 600V.

Material Durability

Options include premium grade 316L stainless steel, best suited for corrosive and hygienic applications or 304 stainless steel, the lower cost alternative that is good for industrial general-purpose applications.

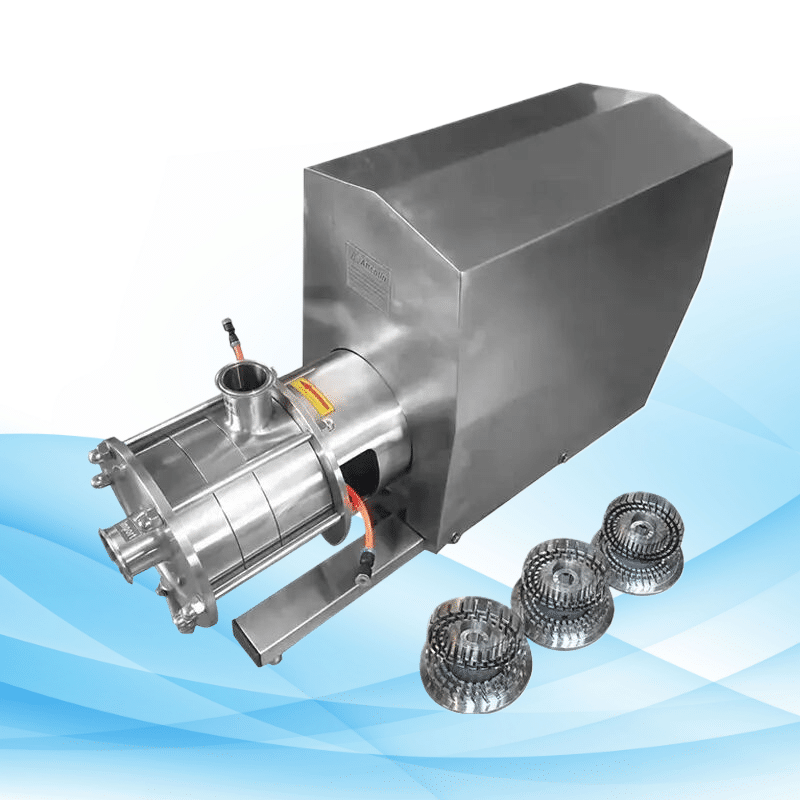

Stage Configuration

Three stage rotor/stator arrangement ensuring maximum emulsification efficiency and quality.

Main Benefits Our Three-stage Emulsifying Pump

Quality Emulsions

Create stable and homogeneous emulsions as required by operational standards easily, reduce product rejects and improve the reliability of the end product with lower emulsifying effort.

Operational Productivity

Time required for processing with multi-stage systems is less than that of single-stage systems, increase throughput and profitability.

Maintenance

Simplified step structure permits rapid disassembly cleaning, lowering downtimes, and improving modular maintenance.

Broad Industry Standards

Many usable materials combined with an extensive array of voltages and powers allow for a diversity of operational demands internationally.

Concrete Industrial Uses

Food Industry

Emulsion technologies yield and formulate mayonnaise, sauces, creams and other textured dairy products with precisely controllable emulsifying efficiency required for industrial use.

Cosmetic & Pharmaceutical

Homogenizes emulsions of creams, lotions, ointments, and serums with highly controlled efficacy and quality standards for potent active ingredients.

Chemical Production

Enables makers to produce emulsions, dispersions, and suspensions that are needed in the chemical processes of industry.

Biotechnology & Laboratory Use

Ideal for the emulsification process in laboratories and biotech facilities to foster product reliability and innovation.

Why Choose Our Three-stage Emulsifying Pump?

Purchasing our Three-stage emulsifying pump makes certain that you have the latest technologies related to the pump’s locomotive and machinery systems in improving the quality of the product and efficiency of work. With our pump, you are not just purchasing a unit. You’re making an investment in an edge over competition in terms of productivity and quality control.

Make that first move in mastering your industrial emulsification systems. Get our Three-stage emulsifying pump now and enjoy unsurpassed reliability and performance.

Frequently Asked Questions (FAQs)

Q: What different features does a Three-stage emulsifying pump have compared to single-stage pumps?

A: The Three-stage emulsifying pump uses a sequential rotor/stator design which refines the emulsion more and more for every stage. This improves emulsion stability and consistency compared to single-stage versions.

Q: Am I able to modify the voltage and power settings of the pump?

A: Yes, the remarks have been changed. Our pumps can be fitted with voltages of 110V to 600V and powers of 1.5kW to 55kW to better fit your requirements.

Q: What is the ideal material for my emulsifying pump?

A: For the surgical, fiendishly corrosive, or hygienic applications in the pharmaceutical or food industries, use 316L stainless steel. For the less critical applications, 304 stainless steel is a dependable and economical choice.

Q: How easy is the maintenance of the Three-stage emulsifying pump?

A: Routine maintenance is made easier by the modular construction of the pump which permits easy removal, cleaning, and regreasing.