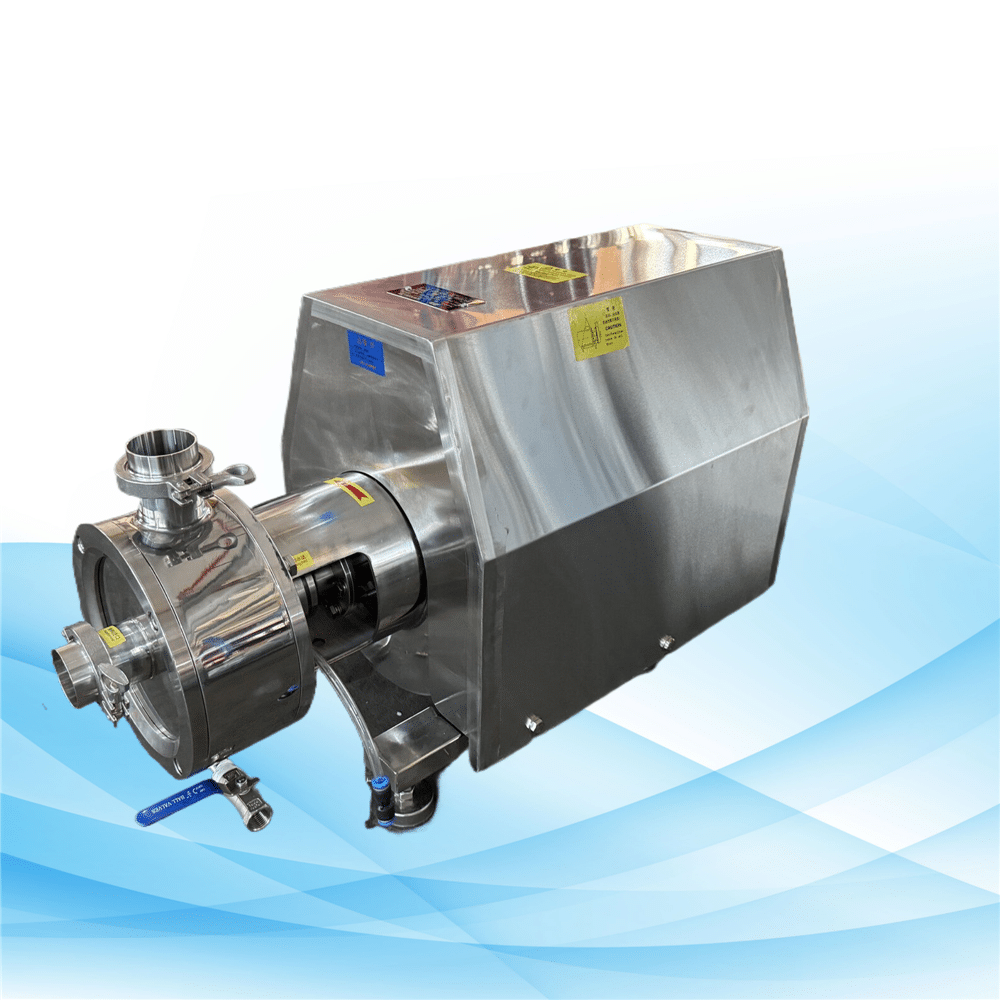

Advantages of Our Single-Stage Pump

✅ Superior Material Options

Select between 316L or 304 stainless steel for your emulsion transfer pump based on the fluid’s compatibility and potential corrosion. 316L offers excellent performance for aggressive emulsions or high hygienic environments requiring sanitary standards, while 304 is ideal for general industrial use.

✅ Wide Power & Voltage Compatibility

To accommodate global standards and varied application scales, our pump supports:

- Voltage options: from 110V to 600V.

- Power configurations: 1.5kW up to 55kW.

Whether you’re equipping a small pilot facility or a full-scale production plant, this flexibility ensures seamless integration.

✅ Smooth Non-Pulsating Flow

The single-stage design guarantees low fluid degradation. For emulsions that require gentle flow to avoid phase separation or shear damage, this feature is crucial.

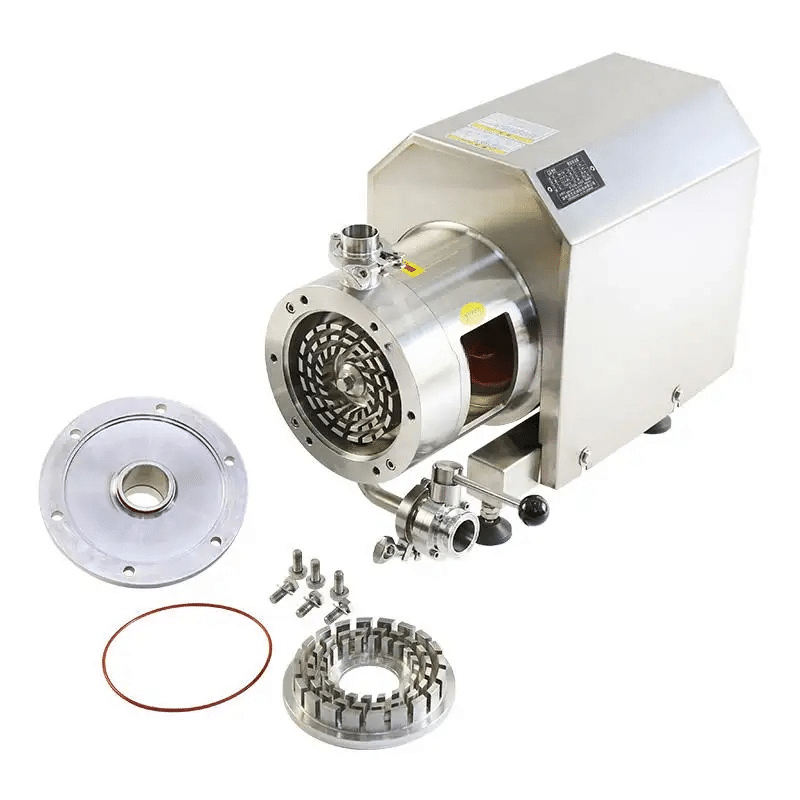

✅ Compact Design, Simple Upkeep

Reduced maintenance downtime stems from a user-centered design. Its small form factor facilitates installation and provides access for cleaning maintenance even in tight spaces.

Application Scenarios – Tailored For Your Industry

Food & Beverage

Best suited to transfer emulsified dairy products, mayonnaise, dressings, or flavoring syrups. The pump guarantees and maintains the delicate product structure consistency and taste over time.

Cosmetics & Personal Care

Designed for lotions, creams, and gels were active ingredients must be uniformly dispersed throughout. The non-shearing mechanism preserves emulsion stability and smoothness.

Chemical Industry

Best for emulsified solvents, detergents, or blends of surfactants. Its chemically resistant construction withstands prolonged contact with harsh chemicals.

Pharmaceuticals

Medical emulsions, syrups, or mixtures can be transported with complete hygiene and zero contamination assurance. These designs can be made GMP compliant on request.

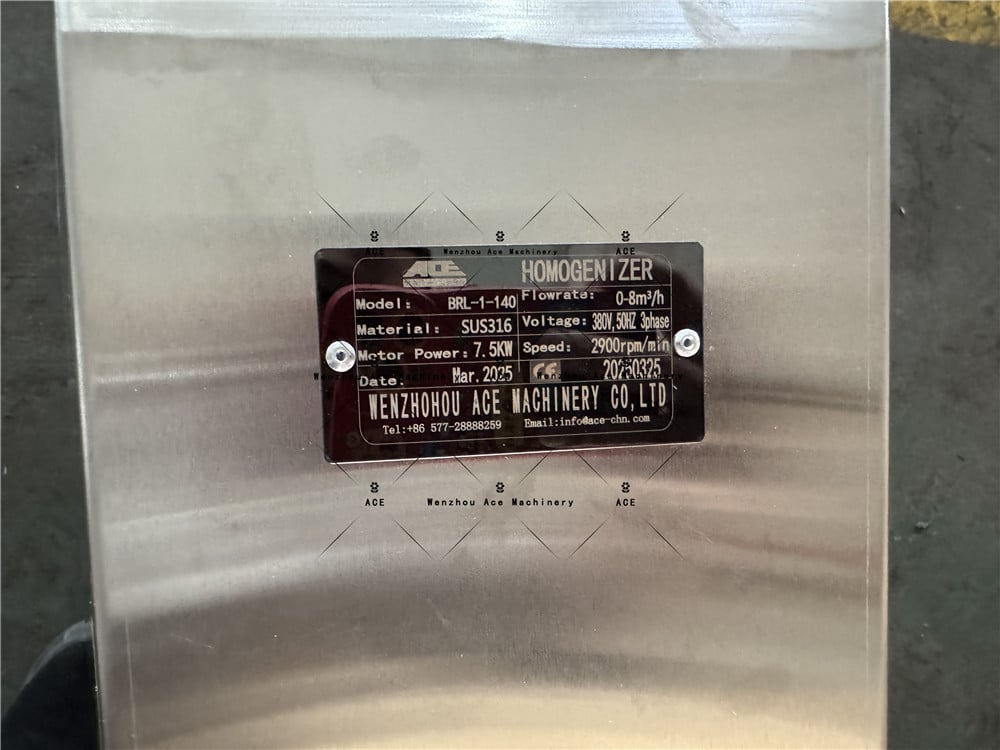

Technical Specifications Summary

| Features | Specification |

|---|---|

| Pump Type | Single Stage |

| Voltage Range | 110V – 600V |

| Power Rating | 1.5kW – 55kW |

| Material Options | 316L Stainless Steel / 304 Stainless Steel |

| Flow Rate | Up to 80 m³/h (Differs with models) |

| Viscosity Handling Up | 100,000 cP |

| Pressure (Maximum) | Up to 10 bar |

| Temperature | -10°C to 120°C |

| Types of Connection | Clamp, Threaded, Flanged |

| Seal Mechanical Options | Seal / Lip Seal |

Why choose Ace Emulsion transfer pump as your lotion transfer solution?

- Designed specifically for any size

- Demonstrated Trust in Critical Production Lines

- Customer-Integrated onto existing systems without issue

- Global support with superior customer service

- Only pump you’ll need for both scaling up or upgrading. Enhances the consistency and efficiency of your fluid handling procedures.

Looking to further refine your production line?

Don’t put up with inefficiencies during your transfer procedures. Switch to a single-stage transfer pump designed for precision that guarantees emulsion quality, reduces downtime, and meets compliance and productivity objectives.

If you would like a quote, get a specialized consultation, or have a bespoke design instead, reach out to our sales division.

Most Commonly Asked Questions (FAQ)

Q1: Can this pump sustain heavy creams and resins as high emulsions and viscous materials?

Our design can accommodate up to 100,000 cP viscosity, which means thick high solid emulsions can easily be handled.

Q2: Is it safe for food-grade applications?

Affirmative. We have food-grade seals with 316L stainless steel variants certified by FDA and EHEDG that deal with food safety and hygiene.

Q3: How do I select the right power and voltage for my region or facility?

Our engineers provide very specific support relative to your region and type of application to ensure correct parameters.

Q4: Is this capability Clean-In-Place (CIP) requestable?

Yes, there are models designed to be compatible with CIP for the food and pharmaceutical hygienic industries.

Q5: What’s the lead time for delivery?

Standard models are shipped within 7–10 business days. They may take 3–4 weeks for custom configurations.