Due to their ability to handle a wide variety of fluids with accuracy and care, Lobe pumps are considered as the best option in different industries ranging from food processing to medicine. For this reason, it is important to know what the strengths and weaknesses of lobe pumps are so that we can make informed decisions about when they should be used in specific applications.

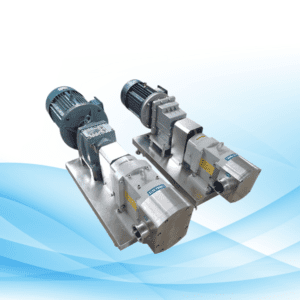

What is a Lobe Pump?

A lobe pump refers to a positive displacement type of pump that employs rotating lobes for fluid motion. The advantage is that these lobes do not come into contact with one another, thus making it possible for such pumps to process different kinds of liquids, including those containing solids, without causing any damage to them. They are usually applied in sectors where hygienic processing cannot be compromised like pharmaceuticals, biotechnology and food industry.

Advantages of Lobe Pumps

Flexibility

It should be noted that lobe pumps can handle many types of fluid viscosities such as; low viscosity liquids or even those having solid particles suspended throughout higher viscosities like heavy creams. This makes them very useful especially when there is need for cleaning because they can easily be cleaned up well hence suiting their application areas which requires cleanliness such as food, beverage and drugs sectors.

Efficiency at Higher Levels

Lobe pumps operate softly, which means that they treat materials gently, thereby maintaining the quality of delicate products like lotions, ointments or edibles. Additionally, this also ensures uniform flow rates, leading into dependable performance during critical processes where consistency matters most.

Maintenance Simplicity

These devices have simple designs with fewer movable components, so keeping them in order becomes much easier than other types thereof available on the market . Cleaning simplicity reduces breakdown periods increasing uptime, hence this feature is highly valued in places where sterility must always be observed coupled with uninterrupted working hours like hospitals ,hotels among others.

Strength

The reliability factor comes into play here since lobe pumps are made using strong materials which enable them to withstand harsh conditions such as continuous running or abrasive product handling. In essence, the durability aspect makes these machines cheaper over a long run despite their higher initial cost.

Silent Functioning

Quietness is another one of the advantages possessed by lobe pumps over their counterparts from different categories because they do not generate much noise during operation, thus making them suitable for use in places where low sound levels are required. It should be noted that quietness feature becomes more convenient, especially within an environment like a food processing factory where employees need to work under minimal distractions while communicating effectively with each other.

Disadvantages of Lobe Pumps

Expensive

As compared to other types of pumps, lobe pump has a high capital requirement. However, this may be offset by long-term benefits, but still it can act as an entry barrier for smaller enterprises with limited finances.

Size and Weight

Larger size along with heavier weight are some disadvantages associated with lobe pumps if you compare them against alternative options available within this category, which means that during installation process or when dealing with space restrictions these factors must always be considered. Portability is also affected negatively due to these attributes, hence limiting its usage in certain areas where movement is necessary, such as construction sites among others.

Possible Contamination

There might occur cross contamination if proper cleaning is not done between uses, where multiple products run through systems using the same pump. This type of potentiality tends to arise more in pharmaceutical industry than any other sector since purity level determines many things including safety precautions during medication preparation stage, however even food processing plants can experience it too.

Solids Sensitivity

For instance; liquids containing small solid particles normally pass through lobe pumps without any problem but on the contrary those having large solids or highly abrasive substances should not be pumped using this machine because they will block up pipes thus reducing efficiency and life span of such equipments.

Capabilities of Lowering Pressure

Normally, lobe pumps are not built for high-pressure applications. They have limited pressure-generating capacity compared to other pump types, a factor that can be disadvantageous when it comes to transporting fluids at high pressures during certain processes.

Summary

Lobe pumps come with several pros which include versatility, efficiency, ease of maintenance as well as durability and low noise operation making them suitable for use in many areas more so the ones that involve hygienic processing in industries. On the flip side they also have their cons such as being expensive, size limited, prone to contamination, sensitive towards solids and lower pressure capabilities. You should take into consideration all these things while selecting a lobe pump so that it serves your need adequately.