Concept Definition for Oil Transfer Pumps

Definition and the role

Oil transfer pump is a unique kind of pump which is used for transferring oil from one container to another. You utilize it for the purpose of working with oil in the most optimal manner so as to work without endangering its effectiveness. These pumps differ in sizing and work, all assuming particular roles. Oil transfer pump has a few key features that simplify oil transfer processes. All these factors ensure that you can operate without glitches and get the desired end results.

Common Applications

You will find oil transfer pumps in many industries. They are useful in vehicle service stations where, for instance, fuel oil from the engine is pumped. In farming, for instance, they are used for transferring oils for agriculture machines. This is particularly common in marine industries where such pumps are used to transfer and relocate oils in bulk containers. These are also used in factories where they are actively used for the oiling of some parts of production machines. Every application presents an oil transfer pump, which is the most effective to use in that specific application area.

How Do They Work?

Basic Mechanism

When, for example, the operation begins with the use of an oil transfer pumps basic operation is simple. First of all, one has to insert the pump’s inlet into the oil’s source. The pump forms a suction which draws oil in through the inlet OIL TRANSFER PUMPS. Once the oil is in the pumps, the oil is discharged from the oil motor out through the outlet. In this process, oil is simply transferred from place to place. There is practically no loss of working fluid and the working fluid does not get contaminated.

Key Components

An oil transfer pump is made up of several key components. To resalt the term ‘transfer’, it is simply a pump for moving oil. Within it, there is an inlet and the outlet, where oil goes in and comes out. The oil transfer pump also incorporates such a unit as a housing which fixes the pump’s internal components. Some pumps include additional parts that are filters which collect oil dust and other pollutants. Identifying such components helps in knowing the oil transfer pump that suits your needs.

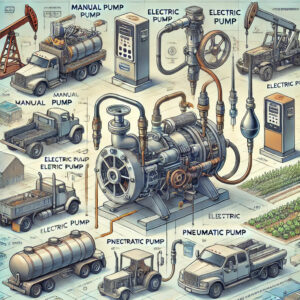

Types of Oil Transfer Pumps

Manual Pumps

They depend on human effort for operation. A lever or a handle is utilized for generating vacuum, and transferring oil from one vessel to the other. Such pumps are basic in nature and do not require the use of electricity or the provision of air pressure.

Features

- Portability: Manual hand pumps are designed to be smaller and therefore portable. They can be used in sites and other places which do not have electricity or power sources.

- Simplicity: These may be mechanical structures but are not complicated with many movable components. This factor makes management and repairing of the pumps simpler.

- Cost-Effectiveness: Among other kinds of pumps, manual pumps are usually the cheapest. Both, the purchase cost, and maintenance cost help you bring back the lost expenditure.

Pros and Cons

- Pros:

- No need of electricity or compressed air.

- Simple operation and maintenance.

- Helps in small jersey business activities.

- Cons:

- Limited amount of flow rate and volume that can be dispensed.

- Uses effort since it’s hand operated making it exhausting.

- Not appropriate for the soaking of a large amount of oil.

Electric Pumps

Electric pumps consist of an electric motor which is directly and fully immersed in oil. They are plugged directly into the plug and function on their own. These pumps are effective and work well in transferring higher quantities of oil.

Features

- High Efficiency: with these pumps, a steady flow of oil is maintained. Thus, oil can be transferred in large volumes fairly easily.

- Automation: these equipment do not need much human control. This enables less work to be done and leads to more returns.

- Versatility: different sizes and volume capacities. Hence relevant one can be accessed.

Pros and Cons

- Pros:

- The oil transfer takes a shorter time.

- It lessens the manual work.

- Can be used for quite some time non stop.

- Cons:

- Dependence on electricity.

- Initial cost higher than that of manual pumps.

- Maintenance work may also be a bit tricky.

Pneumatic Pumps

Pneumatic pumps evacuate oil with the aid of compressing air. Unlike the diesel-engined pump, they are attached to an air compressor and run on air. These types of pumps are effective in an area where electricity is either dangerous or is unavailable.

Features

- Safety: There are incidences when a pneumatic pump needs to be exothermically in nature. These are self-contained units as there are no electric threats from the viscous sheer.

- Durability: These are strong structures that can withstand all difficult environments. Such pumps are to be used with heavy equipment.

- Adjustability: You can vary the flow rate to suit the dynamics of your process by making changes in air pressure.

Pros and Cons

- Pros:

- History Proclavent. No danger risk and from thats the utilization Zone periphery within.

- Cons:

- From all pro points there is always one conoroid unless composite.

Key Considerations When Buying

Flow Measurement

Understanding Pumping Capacity

Every oil transfer pump has to be selected according to the outlines. As one of the people moving it, you need to appreciate the specific amount of oil that must be transferred at a time. A pump such as this handles your oil without any problems. A pump with too low of a capacity leads to uneconomical operations as it tends to take a longer period than what was planned. The operational capacity of the pump should be appropriate to the pump’s application.

Estimating Flow Rate Requirements

The velocity at which an oil pump is able to pump out oil can be defined by flow rate. You should calculate your flow rate needs based on your daily operations. Take into account the amount of oil available and the time you have to take for the transfer. The more the flow rate, the faster the oil movement which is quite time efficient. Know the pressure level required for your pump so that the pump you finally choose will meet those pressure requirements.

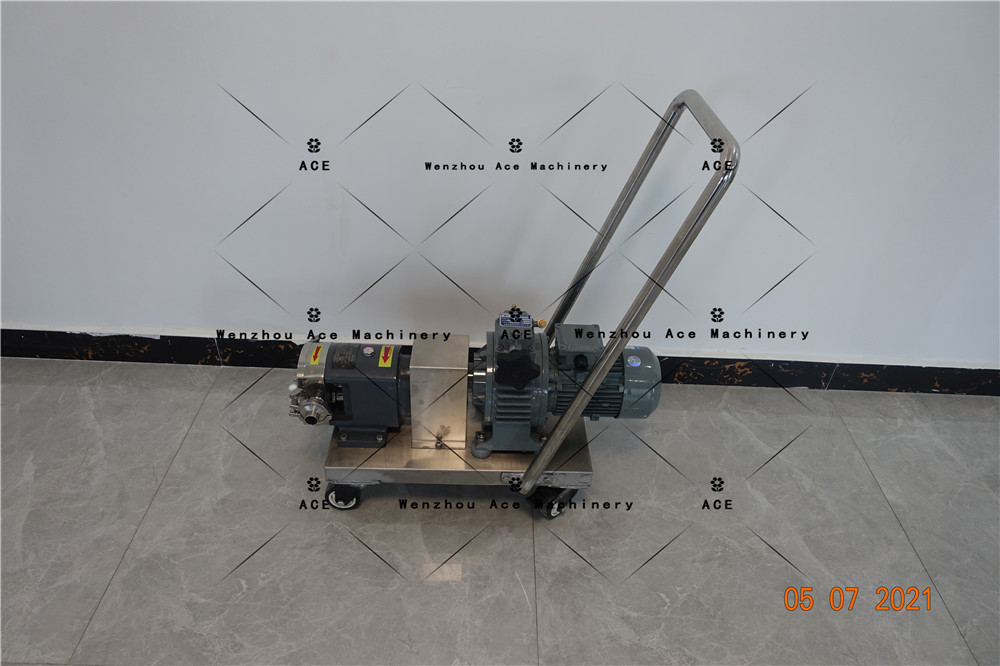

Material and Durability

Type of Materials

The type of oil pumped using an oil transfer pump also takes into account the construction material properties. One must match materials used with the kind of oil being transferred. While most are made of stainless steel variants and aluminum, each variant has its advantages. Since stainless steel has a high resistance to oxidation, aluminum is preferable where light weights are required.

Durability Factors

There is the element of durability because what they are designing is meant to be used over a prolonged period. You will require a pump that is able to withstand harsh conditions and putting it in operation for long periods without ceasing. Some factors that should be present include strong materials and extra seals. They enhance the performance of the pump in service. Consistent durability of the operational pump minimizes maintenance and spare issues.

Compatibility and Safety

Compatibility with Oil Types

This is because not all oil transfer pumps would handle all the types of oils. One must verify if those types of oils to be transferred are compatible with the oil transfer pump. Look at the specifications in order to verify if the pump can be used for the desired oil’s viscosity or with its chemical components. The use of such a pump might be harmful and inefficient in relation to the task.

Safety Features

When carrying out any operation involving an oil transfer pump, safety is the foremost aspect. For example, it is advisable to go for pumps that come with safety features. These include pumps that are provided with valves that close when the liquid level goes too high. Such features prevent destruction, and also guarantee safety when using the equipment. The equipment used as well as people undertaking the operations are safeguarded when really there is a burden on safety.

Installation and Maintenance

Installation Tips

Step by Step Instructions

- Read the Manual: Start by checking the user manual or manufacturer’s instruction. In turn, you will appreciate the special conditions necessary for the efficient working of your oil transfer pump.

- Choose the Right Location: The pump must be put on a steady and level surface. Make sure that it is positioned as close as possible to both the oil source and destination so as to reduce the length of the hoses that are used.

- Secure Connections: Make sure that the inlet and outlet hoses are firmly affixed to the pump or the pipe system attachments. Employ clamps on the hoses which will allow these hoses to pull tight against the fittings to prevent any leaking.

- Check Power Supply: In the case of electric pumps, check that the power source you have conforms to the voltage requirements of the pump. In the case of pneumatic pumps, check to make sure that the air compressor is adequate.

- Test the Pump: Conduct a test run of the pump to look for any leaks or symptoms that may be associated with malfunctioning such as weird noises. Remove the components where adjustments are necessary for easier working conditions.

Common Mistakes to Avoid

- Ignoring the Manual: No one should lose it when trying to skip the manual about how the pump can be used. Always stick by the manufacturer and follow through the instructions provided.

- Poor Hose connections: Do not forget to check all connections, as loose ones will cause leaks. Make sure all connections are tight before starting the pump.

- Incorrect Power Setup: Powering the pump may seem to be straightforward, and yet this is wrong and has often brought serious consequences. Always check the specifications of the source before powering the unit.

Maintenance Practices

Routine Checks

- Inspect Regularly: Examine the state of the pump and its accessories. The turned parts of the motor should not have corrosion or wear. Check hoses and seals for proper conditions.

- Clean Filters: Do not allow any residue to accumulate by putting the filters into regular clean up. Time wastage because of repair is also minimized.

- Lubricate Moving Parts: Put lubricant onto moving parts where necessary so as to minimize wear out of the pump. This minimizes the wear and tear which ensures resilience of the pump.

Troubleshooting Common Issues

- Low Flow Rate: When the flow rate decreases, flow congestion can be suspected in the hoses or in the filters. If congestion is seen, clean out the area or change the component.

- Unusual Noises: If there are any strange sounds, then loose or dispersed components are evidenced in there being air in the system. Where possible, system connections should be properly tightened, after which excess air should be bled out of the system.

- Overheating: When the pump overheats, it is necessary to check where and how often the pump is running. It is often wise to let the machine cool down and check for any pieces of material blocking the machine.

Frequently Asked Questions

How to Choose the Right Oil Transfer Pump?

Critical Questions to Address

While getting an oil transfer pump, you need to ask some key questions:

- What type of oil will you transfer? Different viscosities amount to different varieties of oils. Make sure the pump can accommodate the particular oil type.

- What is the required flow rate? In what time frame should the oil be moved? This assists in pumping out the oil with the right capacity.

- Where will you use the pump? Think about the surrounding temperature. Some of the pumps will be operated in a hazardous area while others are electric.

- Is this Pump Affordable? Each supplier offers their products in prices that suit them and therefore doing this will assist in narrowing the options.

Expert Recommendations

Experts recommend focusing on the following areas when selecting an oil transfer pump:

- Compatibility: Check the pump parts to ensure that they are suitable for the type of oil being used to avoid breakdowns.

- Durability: The more generic the construction of the pumps and the seals, the less frequently the pumps need repair or replacement.

- Safety: Key safety features include self-closing valves and pressure relief valves for enhanced operational safety.

- Maintenance: Opt for pumps that require less maintenance for daily use and have easily accessible replacement parts.

What Are the Costs Involved?

Initial Purchase Costs

The purchase cost of an oil transfer pump is influenced by the following factors:

- Type of Pump: Manual pumps are generally less expensive than electric or pneumatic pumps.

- Capacity and Features: Pumps with higher capacity and additional features tend to be more expensive.

- Brand and Quality: While branded pumps may be more expensive, they often provide greater quality and dependability.

Long-term Maintenance Costs

Keep the following in mind when considering long-term maintenance expenses:

- Volume of Work: Frequent use can lead to higher maintenance and repair costs due to wear and tear.

- Spare Parts Availability: Readily available spare parts can reduce the costs and downtime associated with repairs.

- Routine Maintenance: Regular maintenance prolongs the pump’s functionality and reduces the likelihood of costly repairs.

Conclusion

This guide has focused on the main aspects of oil transfer pumps that you need to know. The types, purposes, and particular features were covered. Also, it was noted how a buyer should approach the issue of purchasing such equipment. It is worth mentioning that operational efficiency and safety both depend on the correct pump selected. Time should be taken to understand the requirements and the possibilities available. Capacity, materials, and compatibility are examples of such factors. This would therefore, result in a wise expenditure. Safety is of utmost importance as well as strength. With good decisions, you enhance the activities of the business and get optimum performance.