When transferring delicate or hazardous liquids, many industries rely on chemical transfer pumps for smooth transfers. These pumps are crucial for the safe, efficient, and reliable movement of chemicals while protecting workers and equipment from unfavorable spills or exposure. This guide will focus on the significance of chemical transfer pumps, their salient features, and how to choose the right one for your use.

What Is a Chemical Transfer Pump?

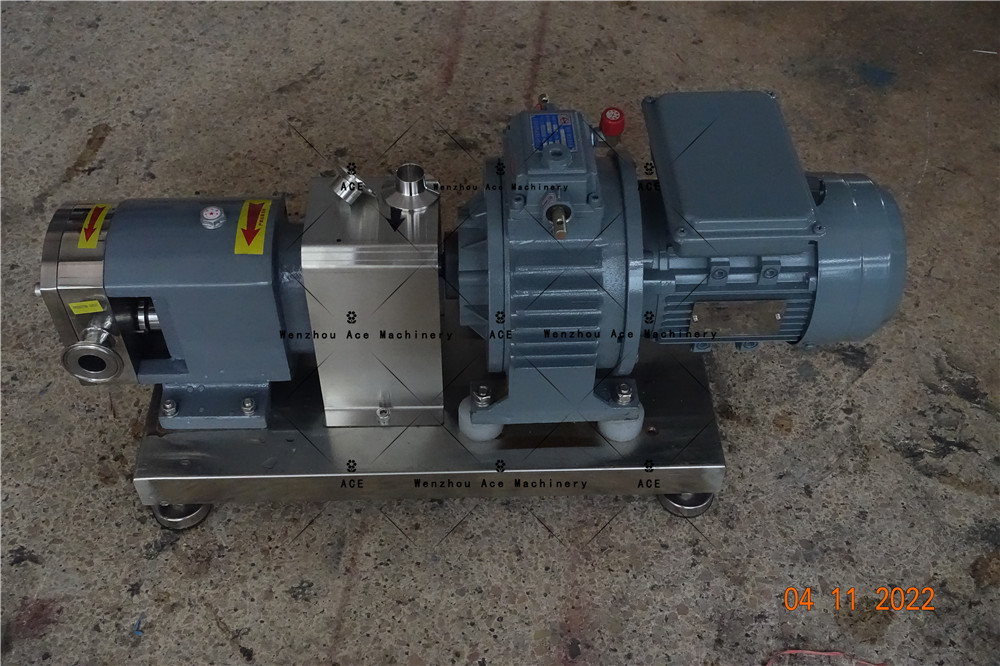

Chemical transfer pumps are specially designed to transport chemicals from one location to another safely. Using these pumps is quite common in pharmaceuticals, food and beverage, manufacturing, agriculture, and waste treatment. They are designed to easily handle different types of liquids from acids and solvents to thick viscous liquids.

Why Are Chemical Transfer Pumps Important?

The primary purpose of handling potentially dangerous liquid, too is often best served by using a chemical transfer pump. If these pumps were not available, chemical leaks along with environmental hazards would become a prominent issue. As a bonus, these pumps help improve efficiency, reduce waste, and maintain the integrity of the liquid being transferred.

Aspects of A Reputable Chemical Transfer Pump

There are many different types of chemical transfer pumps available in the market, which can make it difficult to choose the best one. Let’s go over the most critical parts:

1. Material Resistance

The construction of the pump is crucial. An effective chemical transfer pump will be made from materials that are resistant to the specific chemicals you intend to handle. For example:

- Polyethylene or PVDF: Excellent choice for corrosive acid and alkalis.

- Stainless Steel: Excellent choice for solvents and less aggressive chemicals.

2. Power Output

It is crucial that the pump chosen meets the desired flow rate and pressure. If the pump is oversized or undersized, then it might be damaging or inefficient, whichever way it may be.

3. Manual Intervention Reduction

While it makes the pump easier to use, the self-priming capability does offer some advantages. Many chemical transfer pumps are self-priming, which are easier to use and reduces the need for priming.

4. Overload Protection

Make sure to get pumps that have built-in protection against overpressure and leak detection systems. This will make sure the workers using it are perfectly safe.

5. Environmental Impact

There is a lot of thought devoted to making energy efficient pumps. These don’t just lower the costs of operation, but also have a lesser impact on the environment.

Kinds of Pumps for the Transfer of Chemicals

Several different chemical transfer pumps exist for each distinct application. The common ones are described below:

1. Centrifugal Pumps

Best for centrifugal pumps is the transferring of low viscosity chemicals. They are ideal for applications with high volumes and low pressure.

2. Diaphragm Pumps

This type of pump is good for handling abrasive and corrosive liquids. They are self-priming and will cause damage when running dry.

3. Peristaltic Pumps

Great for viscose or shear-sensitive liquids, as well as contamination avoidance is needed.

4. Gear Pumps

These pumps are designed for high-viscosity chemicals. They provide constant flow rates and are ideal for precise applications.

Long-Tail Keywords You Should Not Miss

For a targeted approach to optimization on Google, the once listed long-tail keywords should be strategically included in the phrasing of the article. Some of the examples are as follows:

- “Chemical transfer pumps specifically design for corrosive liquids.”

- “Chemical transfer pumps with high performance suitable for industrial uses.”

- “Manual self-priming chemical transfer pumps guide.”

- “Chemical transfer pumps for transferring hazardous liquids.”

Different Uses of Chemical Transfer Pumps

With their multi utility, chemical transfer pumps can be deployed in different scenarios. Some of the notable applications include:

1. Industrial Manufacturing

Chemical transfer pumps are required for the transfer of raw materials such as solvents, acids and adhesives in between stages of production.

2. Agriculture

Used for the transfer of pesticides and other related agricultural chemicals, fertilizers and other unsafe liquids.

3. Pharmaceuticals

Make sure the transfer of liquid medicines or solvents is done without contamination.

4. Wastewater Treatment

Pumps aid in the transferring of harsh chemicals used for the purification of water without any mechanical contamination.

Why Use Chemical Transfer Pumps

When used alongside quality self-priming chemical transfer pumps, the following features can be gained.

- Improved Safety: Transferring harmful liquids using pumps diminishes the risk of spills considerably.

- Productivity: Reduces the time and effort it takes to transfer liquids manually.

- Strength: Pumps designed with special materials are not prone to damage from strong, corrosive and abrasive chemicals.

- Cost Savings: Lessens waste and operational downtimes.

How to Choose a Chemical Transfer Pump

Choosing the right pump for your project depends on a few factors:

- Understand your liquid: Keep in mind its viscosity, temperature, and its corrosive nature.

- Understanding flow requirements: Know the volume and speed at which the liquid has to be moved.

- Check compatibility: The materials of the pump must be able to stand the chemical.

- Experts’ advice: Make inquiries from the manufacturers or suppliers on your specific needs.

Some Maintenance Tips on Chemical Transfer Pumps

With proper maintenance, the pump can remain in good condition and continue to serve its purpose without problems arising.

- Regular cleaning: To prevent residue build-up, cleaning the pump after each work is encouraged.

- Check for wear and tear: Check seals, hoses, and other parts for damages.

- Manufacturers guidelines: Maintenance schedules provided by the manufacturer should be adhered to.

Questions that People Most Frequently Ask

1. What is the lifespan of a chemical transfer pump?

Lifespan differs per each pump depending on the material, chemical handled, and usage. With proper maintenance, most pumps last several years.

2. Is it Possible To Use One Pump For Different Chemical Transfers?

The answer lies in the construction and materials used for the pump. Certain pumps can be generalized, while others are specifically made for certain chemicals.

3. Do Chemical Transfer Pumps Consume Less Energy?

In fact, With the advancement in technology, a number of pumps are being manufactured with energy saving design features aimed at minimizing costs as well as their ecological footprint.

4. What do I do When I am Not Sure If My Pump Will Work For One of The Chemicals?

Pumps compatibility charts provide detailed information on this particular query, however, the manufacturer can assist as well.

Conclusion

One can conclude that a chemical transfer pump enables the safe and efficient movement of liquids in different industries, as it is a tool that is considered vital. It is also imperative that the key features, types, and applications of such pumps are understood in making a decision to ensure safety and long-term cost-effectiveness.

Further information or assistance on the right chemical transfer pumps available can be sought from reputable manufacturers and suppliers. The properly chosen pump will not only improve efficiency, but safety to both the people working and the environment.