Comprehending Lobe Pumping Operations: A Walkthrough

Lobe pumps are used in many industries because they can handle fluids that range from thin liquids to heavy viscous materials. Knowing how to operate a lobe pump effectively is important in keeping it working well and avoiding problems. This article will guide you through a step-by-step process for getting the most out of your lobe pump.

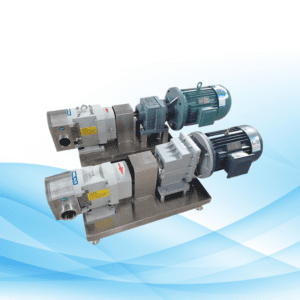

Understand the Parts of a Lobe Pump

There are several key components of a lobe pump that you need to know about before operating it:

- Pump Housing – It is the outer casing which encloses both lobes and their working area.

- Lobes – These rotating elements move fluid through the pump; they do not touch each other since they are synchronized.

- Inlet and Outlet Ports – Fluid enters into or leaves the system through these points respectively.

- Shafts and Bearings – Lobes are supported by them and allow for their rotation.

- Seals – They prevent pumped liquid from leaking out along shafts or at other joints where clearance between parts is necessary for relative motion between them during operation (dynamic sealing).

Check Setup

Ensure that your installation follows manufacturer’s guidelines; make sure:

The base on which it stands should be stable enough;

All connections made with inlet/outlet ports must be airtight and properly fixed;

Drive system (motor etc.) alignment should be correct while ensuring proper linkage with power source.

Prime The Pump

Priming involves filling up all spaces within a device before switching it on to avoid dry running, which may lead to damage such as:

Fill the pump casing with fluid being pumped or any compatible one if not available.

Make sure no air is trapped inside lines connected to suction side (inlet) of lobe pump from where it draws its content before starting up this machine altogether.

Start The Pump

After having successfully primed your equipment, follow these steps during operation:

Begin by switching on the power supply, then running at low speeds until the desired amount of liquid has been introduced gradually into the system;

Watch closely as fluid flows through various parts, checking for smoothness without any abnormal sound or vibration;

Increase speed stepwise until required flow rate is attained while ensuring steady state flow.

Observe Pump During Use

Continuous watching is necessary when this device is functioning, since:

Pressure and Flow Rate – Ensure that working pressures fall within recommended values also check if blocks exist along channels;

Temperature – Monitor both housing’s heat level together with pumped media; excessive temperatures might indicate friction between mechanical elements, among other things;

Lubrication – Regularly inspect lubricant application points for wear signs caused by rubbing components against each other during normal duty cycle.

Stop The Pump Correctly

If you want to terminate operation or shutdown the unit completely, follow these guidelines:

Reduce revolving speed gradually to avoid fluid hammering plus pressure surges which may damage equipment;

Switch off power, then wait until it stops rotating entirely before taking further action, like closing valves positioned between inlet/outlet ports to prevent backflow.

Maintenance Troubleshooting

These are some of the activities performed in order to keep your machine fit most times:

Check Seals And Bearings – Frequently look out for leakages around them due to wear, replace where necessary;

Clean The Device – Take apart, occasionally clean away materials that interfere with its efficiency over time;

Detect Problems -In case anything seems unusual such as reduced flow rate, strange sounds or leakages refer manufacturer’s manual on how to solve such issues alternatively consult an expert.

Conclusion

To make sure that your lobe pump performs with optimum performance and dependability, you need to do this. You have to keep a regular watch on it and also take care of it well so as not to experience any technical difficulties. Getting to know how each part works and what they do is essential for operating different liquids successfully through these devices, thereby making them efficient in their work, which will in turn make everything easier for you while dealing with fluids.