Understanding Transfer Pumps

What is a Transfer Pump?

Definition and Basic Function

A transfer pump is any mechanism designed for moving liquid from point A to point B. It does so by creating a difference in pressure that draws fluid into the pump, then pushes it out again. These types of pumps can work with various liquids like water, fuel, oil, or even coolant due to their versatility in application.

Types of Transfer Pumps

There are several different kinds of transfers pumps – each one has its own specific job it was made for:

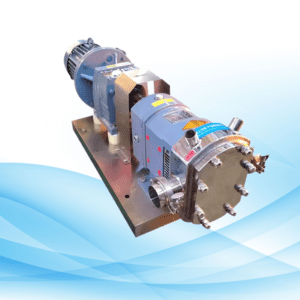

- Gear pumps: These types use gears which rotate within themselves, thereby displacing fluid from one side to the other at high pressures necessary for certain applications.

- Vane pumps: These have sliding vanes that move back and forth along slots as they rotate, thus creating suction on low viscosity fluids.

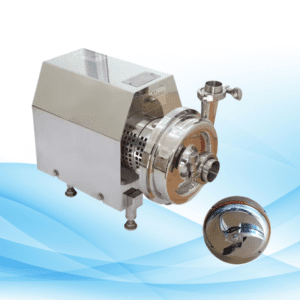

- Impeller pumps: These employ an impeller blade wheel which spins rapidly causing liquid around it to move through centrifugal force, hence producing higher volumes, but lower pressures required by some tasks.

- Variable speed pumps: As the name suggests, these devices enable you to vary the rate of flow, giving room for diversity in usage.

- Reversible direction pumps: With such machines, one can change the flow direction easily, making them very handy during an oil change or similar operations.

Key Components of a Transfer Pump

Motor

This powers the whole system; therefore, when selecting, consider if electric or gasoline-powered will best suit your needs. Electric motors run quietly while needing less maintenance; on the other hand, those using petrol offer more power output coupled with portability benefits. Choose wisely!

Pump Mechanism

The mechanism behind how it works – This part creates the difference in pressure required for fluid movement. Depending on what the pump is intended to do, you may have gears, vanes, or impellers among others, each with its own strengths and weaknesses.

Hoses and Fittings

To transport fluid, connectors are used, such as hoses and fittings which attach them to pumps. It is important to have good quality hoses for efficient transfer of liquids. On the other hand, fittings help secure those pipes onto machines, preventing leakage during operation. Always label all your pipes correctly according to where you will be attaching them at the transfer pump point. Make sure that whatever type of hose or fitting used should be compatible with the liquid being conveyed.

Preparing to Use a Transfer Pump

Safety Precautions

Personal Protective Equipment (PPE)

Whenever handling any kind of device, wear appropriate personal protective equipment (PPE). This includes wearing gloves, safety goggles, and protective clothing if necessary. The gloves protect hands from dangerous substances, while safety glasses shield eyes away from splashes that might contain harmful chemicals, too. In case there are some hazardous liquids involved in work, it would be advisable to also have on overall clothing designed specifically for such purposes. All PPE must fit properly so that they can provide the maximum level of protection required by the user.

Safe Handling Practices

These are ways through which accidents can be avoided when using these gadgets; read the manual before use always, make sure one knows how it operates best – Never run dry because this will damage parts, then check efficiency levels by not overloading; keep the area near so as not to trip over anything especially during operation time plus inspecting regularly to see whether there is a need for replacing any worn-out component instantly.

Tools and Materials Needed

List of Required Tools

Before starting, ensure having everything ready:

- Wrenches for tightening fittings.

- Screwdrivers useful when assembling different parts together.

- Pliers used mainly for securing hoses tightly.

- Measuring tape helps determine the accurate length needed per given hose.

- Bucket may come handy in catching excess fluids within the vicinity.

Having all these tools nearby will make setting up easier.

List of Materials Required

Prepare the necessary materials for the job. Things that are required include:

- Hoses which go with the fluid being transferred.

- Fittings that match the pump and hoses.

- An electric source for electric pumps.

- Fuel for gasoline-powered pumps.

- Lubricant for lubricating parts in motion.

Ensure all materials are okay and suitable for use with a particular fluid. This will enable you to operate well.

Step-by-Step Guide on How to Use a Transfer Pump

Setting Up Your Transfer Pump

Assembling Your Transfer Pump

Start off by collecting all needed components and tools. Follow the manufacturer’s manual when putting together the pump, ensuring each part fits tightly; tighten any loose bolt or screw that may cause leakage later on; make sure the motor aligns properly with the pump mechanism.

Connecting Hoses Together

Locate intake and discharge ports on your selected pump, then attach labeled hoses accordingly. Ensure they are fixed using clamps or fittings so as to create a tight seal which prevents leaks from occurring; also check if there is any twist in the hose which might restrict flow, causing damage later during operation.

Operating A Transfer Pump

Priming A Transfer Pump

Fill up the pump with liquid in order to eliminate trapped air; use a funnel where necessary while pouring into the intake hosepipe; manually turn the device if needed so as to expedite the movement of the substance, but take note that before starting the engine it must already be full.

Starting A Transfer Pump

Connect the power supply system; plug the electric one into an outlet or feed the gasoline engine by filling its tank then ignite it before switching on these devices, thus allowing fluid to pass through them at different speeds based on the variability setting.

Monitoring The Process Of Transfer

Keep watching the level of liquid inside the source container but don’t forget about checking if there is any leakage point as well as a blockage place plus listen attentively to whether abnormal sound is coming out from this machine; otherwise, stop working immediately after noticing something wrong with it.

Shutting Down & Cleaning Transfer Pumps

Properly Shutdown

Turn off the pumps and disconnect them from the power source; let them cool down if they have been running for long hours; open the discharge valve to release off pressure within the hoses, then remove them, followed by draining any remaining liquid left behind.

Cleaning & Maintenance Tips

Clean pumps together with their respective pipes once finished using every time; employ appropriate detergent depending on the type of fluid handled plus inspecting the device for worn-out parts should be done regularly where necessary hence replacing them without delay; keep in a dry place always until next required i.e., a safe place. Regular checkups enhance the durability and efficiency of such equipment.

Conclusion

Transfer pumps are very essential when it comes to transporting fluids from one location to another. To be more skillful in operating this machine, practice is key. Thus, follow all safety measures and correct procedures, which will enable you to have a smooth process while carrying out your work. Seek more information from other sources if the need arises in order to gain a deeper understanding of different aspects related to these devices. Enjoy pumping!