There are various industries that utilize rotary lobe pumps to transfer fluids that are difficult to pump. These devices are quite efficient since they could handle a myriad of different pumping materials such as thick slurries and shear sensitive liquids. The goal of this article is to extensively analyze some of the inner workings of a rotary lobe pump such as what it is, how it works, its salient features, its major applications and why it leads among other similar pumps in popularity.

How Do Rotary Lobe Pumps Work?

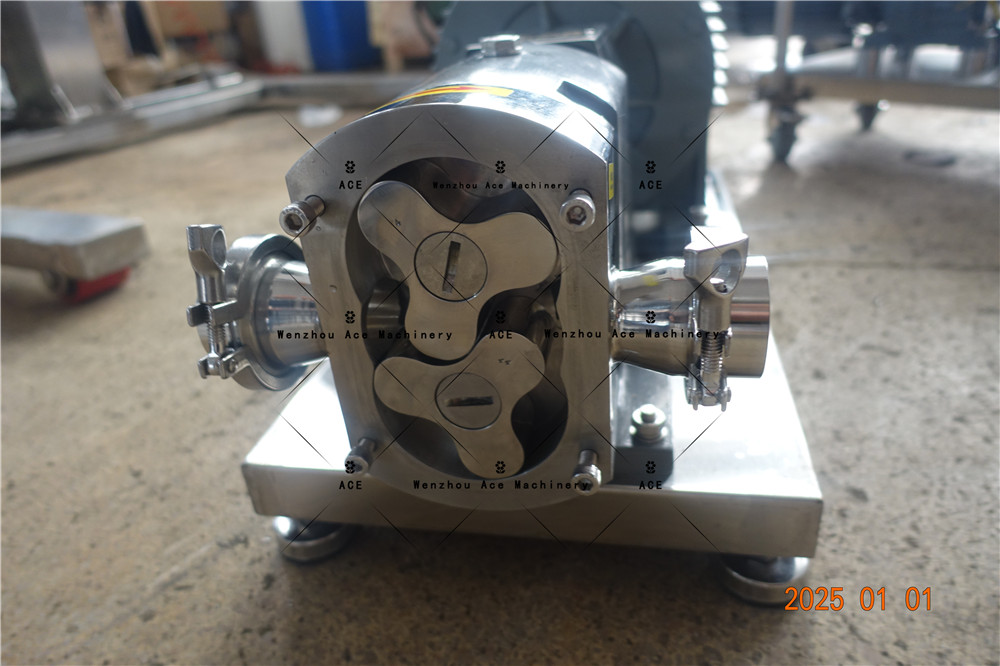

Rotary lobe pumps function by transferring fluids through the use of positive displacement pumps. In the case of a rotary lobe pump, two or more lobes frequently known as rotors are used to shift the fluids from one point to another. Gradually, as the rotors spin in opposite directions, several cavities are created in a continuous manner which assists in the movement of fluid through the whole system. These pumps work remarkably well when severely viscous fluids, slurries or fluids with suspended particulate matter are to be dealt with.

Rotary lobe pumps utilize mechanical action to push fluids around which means, as compared to centrifugal pumps which works on the principle of high-speed rotation and fluid pressure, these pumps are remarkably more efficient. They are even able to accommodate little bits of suspended solid material in the liquids. This makes them invaluable in applications that require a gentle yet consistent flow.

What is the Working Principle of a Rotary Lobe Pump?

A rotary lobe pump operates in a way similar to a positive displacement pump. Here’s the working cycle:

Fluid Inlet

The fluid is fed to the rotary lobes of the pump.

Sealed Cavities

As the lobes turn, they form sealed cavities between the lobes and the casing of the pump.

Fluid Movement

These cavities are filled with fluid and shifted out through the pump room.

Fluid Discharge

The fluid is ventilated from the opposite side of the pump.

The flow of the fluid is very carefully controlled, as the pump is designed in such a way that the lobes are capable of working without subjecting the pump parts to any shear forces that could result in fluid disruption.

Key Features of Rotary Lobe Pumps

A wide selection of functions are present in rotary lobe pumps, which make them appropriate for different industries:

- Positive Displacement: No matter how high the pressure is, the flow level remains constant.

- Gentle Fluid Handling: Rotary lobe pumps can be used for shear sensitive fluids such as food and pharmaceutical products due to their construction.

- Self-Priming: Most rotary lobe pumps are characterized by self-priming, meaning that the pump can operate even at low levels of fluid.

- Variable Flow Rates: Using a rotary pump allows for a single person to adjust the flow rate depending on the job at hand and the task, resulting in improved flexibility.

- High Efficiency: The rotary lobe pumps are capable of easily scheming over a broad gamut of fluids without having to spare any effort.

Benefits of Utilization of Rotary Lobe Pumps

In industrial and engineering application, rotational lobe pumps have a wide array of benefits.

1. Multifunctional

These kinds of pumps can upend a wide range of slurries, viscous liquids and suspensions. This makes the pump economically reasonable for other industries such as food, pharmaceuticals and most importantly, wastewater treatment.

2. Careful and Accurate Flow

Unlike rotary centrifugal pumps which can ruin sensitive fluids by shear damage, rotary lobe pumps ensure consistent gentle flow pumping which does not shatter the materials during the process.

3. Low Needs of Maintenance

Due to the simplistic style of rotary lobe pumps, they need a low amount of maintenance as compared to the other types. Easily replaceable parts that are designed for wear and tear and long-lasting with accuracy.

4. High Suction Lift and Self-Priming

The self-priming capability of rotary lobe pumps is another distinct advantage, allowing them to operate under low or variable liquid levels without any difficulties.

5. Tough and Compact

Rotary lobe pumps are compact and tough from the outside; they are designed to work even in harsh environments, thus ensuring reliable and excellent performance.

The 3 Greatest Makers of Rotary Lobe Pumps

A number of industries are served by the maker of rotary lobe pumps as their leading products which are considered highly reliable, durable, and efficient in accomplishing particular industrial tasks. These are the best three firms in the profession:

1. Wangen Pumps

Wangen is a renowned rotary lobe pump manufacturer who offers engineered solutions to specific pumping challenges including viscous sludges, food and chemical products. Wangen’s pumps are mostly recognized for their strength and accuracy.

2. Ace lobe Pump

Ace lobe Pump is the next company on the top of the list because they have a broad range of rotary lobe pumps. Their name has become well known in the industry because of the high performance of the Ace Rotary lobe pumps in food processing, pharmaceuticals, and water treatment.

3. Netzsch Pumps

Netzsch is well known for their exceptional workmanship on rotary lobe pumps, which are used in industrial or laboratory uses. Their pumps have a distinctive feature of constant flow rates and gentle fluid handling, which makes them more efficient in various industries.

Common Applications of Rotary Lobe Pumps

Due to the multipurpose nature of rotary lobe pumps, it is accessible in almost every industry. A few of the more common applications are:

- Food and Beverage Industry: Gently pumping thick products including sauces, creams, and jams to maintain their texture.

- Pharmaceuticals: Moving sensitive liquids and chemicals with precise care.

- Wastewater Treatment: Relocation of sludge and other thick wastes within water treatment establishments.

- Chemical Processing: Transferring aggressive fluids and chemicals needs special attention.

- Oil and Gas: For the pumping of thick oils and emulsions.

FAQs about Rotary Lobe Pumps

1. What types of fluids can rotary lobe pump handle?

Rotary lobe pumps are highly versatile; they can pump slurries, pastes and liquids of all consistencies. These are often used in food processing, pharmaceutical, and wastewater treatment industries.

2. Do rotary lobe pumps have self-priming capabilities?

Most rotary lobe pumps available today are self-priming, which means they are able to commence pumping even when there is air present in the system, or the pump casing has not been completely filled with fluid.

3. What is the procedure for maintaining a rotary lobe pump?

Among all the different pump types, rotary lobe pumps are some of the lowest in routine maintenance. However, it is recommended that the lobes and seals periodically be inspected and any worn out components replaced.

4. Are rotary lobe pumps suitable for driving fluids with high viscosity?

Yes, rotary lobe pumps are able to drive fluids with high viscosity with ease. Problems such as transferring thick slurries, pastes, and other heavy liquids that would be difficult to move rotary lobe pumps can transfer without issue.

5. What industries use rotary lobe pumps?

With their gentle fluid handling, rotary lobe pumps are used in various industries such as food and beverage, pharmaceuticals, chemicals, wastewater, and oil and gas industries.

Conclusion

Ultimately, rotary lobe pumps are one of the most flexible and dependable pumps in a variety of industrial domains. Their design features that enable the pumping of viscous fluids, a stable flow rate, and high efficiency make them a crucial device within many industries. Rotary lobe pumps are the ideal method of pumping food products, chemicals, or even sludge while still maximizing the operational efficiency and integrity of the fluid.

Being familiar with the unique characteristics, benefits, and uses of these pumps, helps you select the most optimal solution for your system. You are being presented with a wide variety of options, starting from renowned companies such as Wangen Pumps, Ace lobe Pump, Netzsch to ensure your system operates smoothly, reliably, and efficiently.