Key Features and Advantages

1. Exceptional Durability

The durable and robust nature of this machine is because of the high-quality stainless steel used in its construction, which almost assures the durability of the device. The grade of 316L stainless steel tends to be expensive as it is best suited for industries that delve into chemicals and dealing with moisture-rich environments, as over time it develops a strong resistance to corrosion. However, the 304 grade does come in at a cheaper rate than its counterpart while ensuring strength for basic operations.

2. Customization that Suits Your Requirement

The Customization Options which fit this High Shear Mixer are actually one of its key features. With a power range of 1.5 KW on the lower end and 55 KW on the higher end, it can easily be molded to the intensity and scale of your operations. Furthermore, the specified voltage range of 110V to 600V amply enables the mixer to be used in any geographical location without worrying about the local power grids.

3. Revolution Mixing Technology

The advanced rotor-stator mechanism featured in the High Shear Mixer ensures that materials are finely homogenized and dispersed. As the materials are subjected to high-rotational speeds, a high shear force enables the particles in the materials to degenerate, resulting in a mix that is ideal. Whether it is a thick paste, emulsified liquids, or fine powders, the mixer delivers perfect results every time.

4. Cost Effective

The High Shear Mixer features a powerful motor without compromising energy efficiency, thereby being cost-effective. The power range of 1.5 KW to 55 KW makes it ideal for all businesses, while at the same time making it energy efficient. In effect, the efficient motor design saves energy while allowing for greater production at a lower cost, which results in excellent productivity.

5. Wide Applications

We can mention a number of industrial areas where the High Shear Mixer can be effectively used, including:

- Food Industry: Best suited for emulsions, sauces, creams, and batter mixing where the end product requires consistency and uniform texture.

- Pharmaceuticals: Employed for the preparation of creams, ointments, and oral suspensions, allowing particle size and uniformity control of the finished product.

- Chemicals: For dispersing powders in liquid to produce quality emulsions and suspensions forms used for paints, coatings, lubes, and other chemicals.

- Cosmetics: Such as lotions, serums, and other makeup, combined with other solutions to create an even consistency for a smoother-like finish.

6. Ease of Use

The High Shear Mixer has a simple and practical control panel, making it very user-friendly and easy to handle or maintain. The operators are able to rapidly change speed settings, measure performance, and adjust the mixing parameters as necessary to suit the desired and expected term. Another feature of the machine is that there is minimal downtime for an operator because it is easy to maintain and does not require significant time or attention.

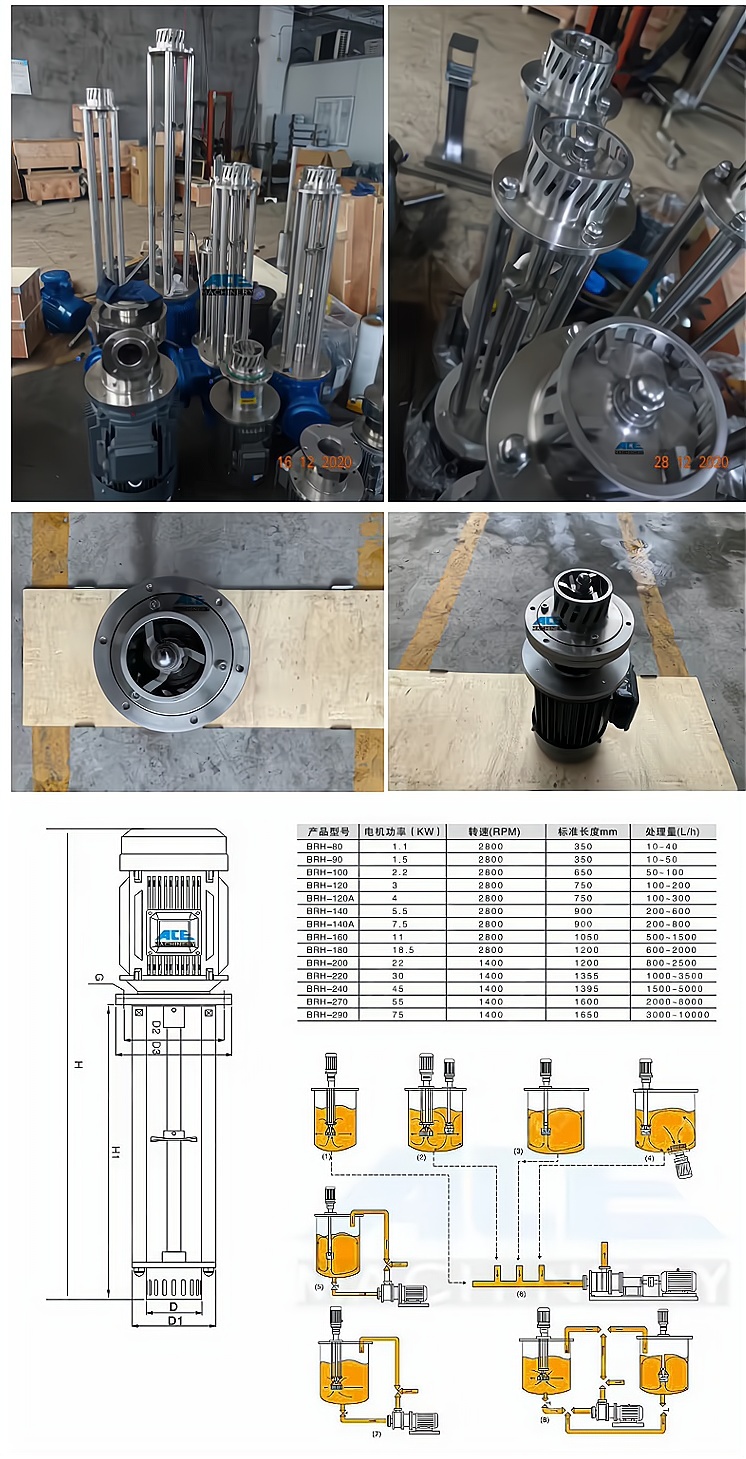

Technical Specifications

- Power Range: 1.5kw to 55kw

- Voltage Options: 110v-600v (demand specific)

- Materials: 316L or 304 stainless steel depending on the requirements

- Speed Settings: Variable settings from low to high speed depending on the type of equipment used

- Mixing Type: Superior shear mixing high shear rotor-stator for enhanced dispersion

- Applications: Various food processes, pharmaceutical, chemical polishing, and cosmetic industries

- Design: Space efficient, useful for household purposes and industrial level too

Why Choose the High Shear Mixer?

High Shear Mixers are arguably one of the most effective, tough, and versatile machines available on the market. Its special features ensure firms maximize output and quality from their mixing processes. Be it delicate formulations or high viscosity materials, a high shear mixer promises excellent results.

- High Efficiency: Any blending process is straightforward and final results dependably retrieved within a suitable time frame.

- Customizable: You can easily get the necessary dual power and voltage as you require.

- Durable Materials: Fabricated from robust, high-grade stainless steel.

- Cost-Effective: Systematically and effectively designed device to save some operational costs.

- Versatile: Many industries would find these finely made devices useful for different purposes.

With this High Shear Mixer, you are not just purchasing a machine but rather a highly reliable and permanent resolution for improving manufacturing productivity, product quality, and operations efficiency.

Applications in Action

Picture your assembly line where the ingredients are being combined in a uniform manner without any clumping. Whether it is a food factory mixing sauces, a pharmaceutical lab making creams and emulsions, or even a cosmetic plant making blended serums, there’s no need to consider how difficult it is to accomplish these activities because a High Shear Mixer accomplishes them effortlessly. All that is required is adjusting the rotating speed settings depending on what you wish to accomplish, this guarantees that you get perfect outcomes every time.

This machine may mix materials with consistent quality and likewise emulsify them depending on the durations and sequences, which might eliminate the problems of high viscosity and delicate product turns. This device simplifies processes in various industries such as cosmetics or even pharmaceuticals while meeting the regulations and providing consistent quality and performance to their products.

Common Questions

1. What is the power range for the High Shear Mixer?

The High Shear Mixer has a trending power between 1.5KW to 55KW, so there is something to work for everybody, either big or small.

2. What voltage options are available for the High Shear Mixer?

Clients are provided voltages between 110V to 600V which will be able to work with your electrical system wherever you are.

3. How much control do I have in altering the specifications of the mixer?

Indeed! The High Shear Mixer has a great deal of modification flexibility. We provide different power, voltage, and material options (316L or 304 stainless steel) to ensure the equipment suffices your production needs.

4. Does the High Shear Mixer utilize any other material than steel?

The High Shear Mixer is offered in two types of high-grade stainless steel. It is available in 316L, which is more suited to meet environments likely to result in corrosion, and 304 stainless steel, which is a cheaper alternative for mixing purposes.

5. Which industries is the High Shear Mixer useful in?

This mixer is well suited to food and beverage production, pharmaceutical ingredients, chemical manufacturers, and cosmetics. It offers strong performance where accurate dispersing, emulsifying, and homogenizing are required.

6. Am I able to operate and maintain the High Shear Mixer without difficulty?

Yes, the High Shear Mixer has a very straightforward operating panel, easy maintenance, and repair needs so that downtime is reduced, and the device is able to perform optimally.

The High Shear Mixer is the industry answer for businesses that want to improve their mixing practices. With its rigid construction, custom-made machinery, and energy-saving options, it guarantees value in an array of industries from food to drugs. With such a mixer, whether improving product quality, enhancing production, or minimizing energy costs is the requirement, such a mixer guarantees to have one surpass the competition.

Do you want to improve your mixing process? Get in touch with us today so that you can make an order and take the next step towards efficiency and quality in your operations.