Advantages of the High Shear Batch Mixer

Highly economical mixers as such show no competitors when it comes down to precision mixing and emulsifying.

Unparalleled Accuracy in Mixing with 11KW High Shear Batch Mixer

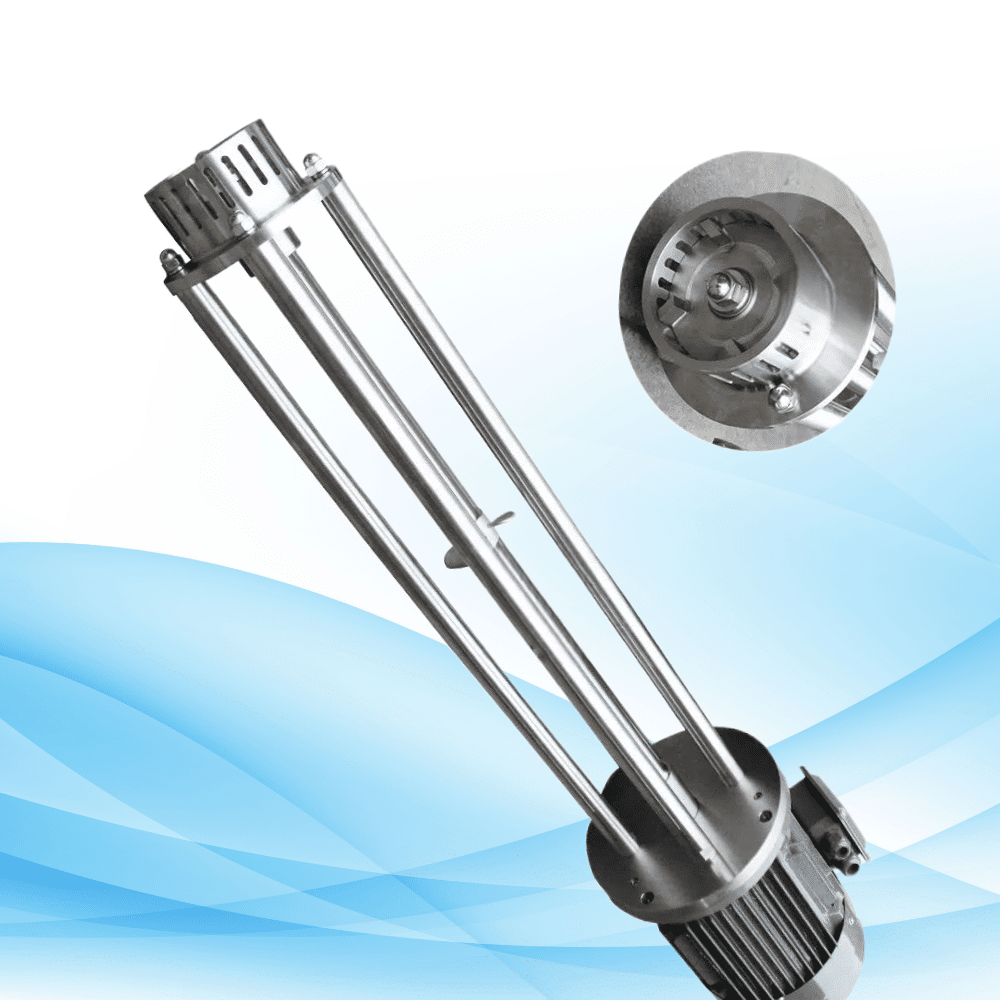

Offered with a high-speed rotor-stator assembly, this machine achieves the unrivaled precision of separating particles to the micron level. Once more, showing unwillingness to fail your expectations, it permits the blending of non-miscible liquids and powders into highly viscous bases.

Vertical Control Customization and Power

11KW Standard (0.75KW to 55KW) and 110V to 600V make this device adjustable to your infrastructure. This means that existing setups won’t be disrupted. This saves a tremendous amount on retrofitting expenses.

Withstanding Construction Quality

Pick between corrosion-resistant 316L stainless steel (for aggressive chemicals) or food-grade 304 stainless steel (when worried about costs) to meet FDA, GMP, and EU requirements.

Intelligent Control Systems

The more sophisticated models have PLCs for automated control of speed, temperature, and batch timing, creating new levels of efficiency and productivity whilst minimizing human error.

Applications of the High Shear Batch Mixer

Pharmaceuticals & Nutraceutical

Application: Emulsifying injectable formulations and homogenizing vitamin suspensions.

Result: Critical bioavailability and compliance with regulatory requirements due to uniform particle size distribution, <5µm.

Food & Beverage Production

Application: Creating stable salad dressings, sauces, or dairy analogs.

Result: Elimination of ingredient separation with smooth texture and extended shelf life.

Cosmetics and Personal Care

Application: Blending lotions, creams, or serums with heat-sensitive actives.

Result: Preserved delicate compounds’ efficacy and luxurious consistency of retinol or peptides.

Specialty Chemicals

Application: Dispersing nanoparticles into coatings, adhesives, or lubricating oils.

Result: Optimized particle dispersion improves product performance.

Technical Specifications in Summary

| Parameters | Specifications |

|---|---|

| Power Utilization | 0.75KW – 55KW (11KW is a standard option) |

| Voltage Options | 110V – 600V (single or three-phase) |

| Material Options | 316L / 304 Stainless Steel |

| Shear Rate | Up to 25 m/s |

| Max Viscosity | 50,000 cP |

| Mixing Capacity | 50L – 2000L (customizable) |

Why Choose This High-Performance Shear Mixer Over Competing Models?

- Energy Efficiency: Optimized motor design decreases power expenditure by 20% compared to traditional mixers.

- Easy Maintenance: Rotor-stator apparatuses allow for fast cleaning and part substitution, resulting in lesser downtime.

- Scalability: From R&D labs to full-scale production, the modular design of the mixer enables smooth scale-up.

FAQs: Answering The Most Asked Questions

Q1: Can this mixer endure abrasive materials?

A: Yes. The 316L stainless steel variant is perfect when dealing with abrasive or corrosive materials due to enhanced wear resistance.

Q2: Is there a possibility for this mixer to work with a CIP (Clean-in-Place) system?

A: Certainly. All parts with contact areas are constructed CIP/SIP compatible, making it feasible for sanitary-sensitive fields to meet cleanliness requirements.

Q3: What warranty and support come with the product?

A: The warranty of two years regarding the mechanical parts as well as 24/7 technical support and remote availability of replacement parts.

Q4: How long does the product take to deliver?

A: For standard units, shipping occurs in four to six weeks while expedited options are available for critical requisites.

Ready for an Overhaul in the Way You Handle Mixing?

The 11KW High Shear Batch Mixer is not a mere piece of equipment—it is a glaring opportunity to maximize quality and efficiency in the production process. Its custom configuration options, industrial strength, and wide-ranging capabilities enhance the ease of manufacturing through quicker cycle times, reduced waste, and improved product quality.

Contact our engineers now to ask for a detailed quote or schedule a customized demonstration. We’ll be glad to support you in finding the best layout for your business processes.