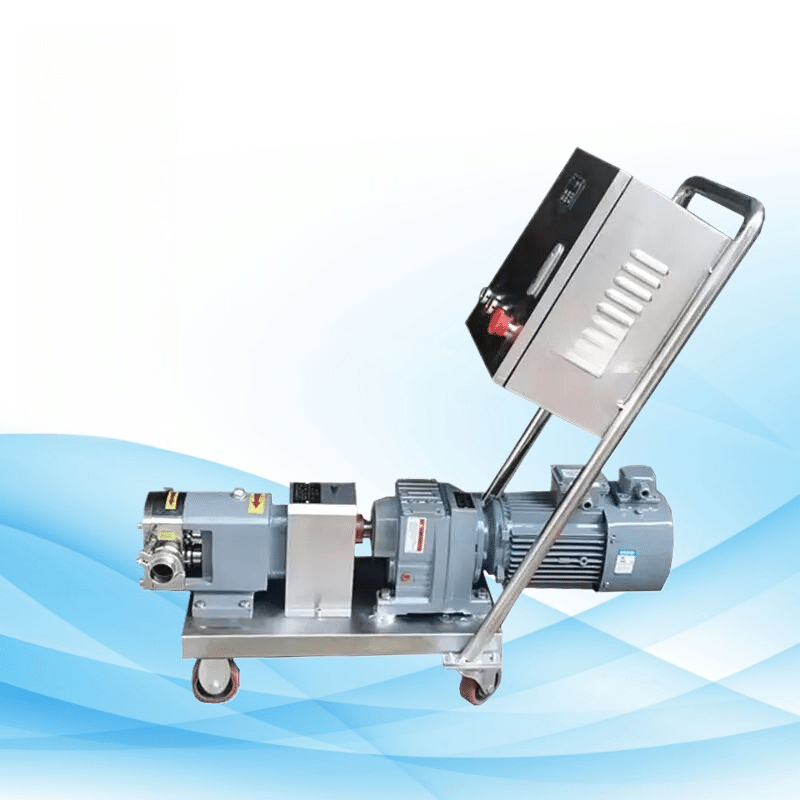

Key Features and Advantages

High Efficiency & Precision Flow Control

- Easily manages to contain shear-sensitive materials and liquids that have a high viscosity or are delicate.

- Devoid of pulses, guarantees a steady flow and doesn’t degrade materials.

Robust & Hygienic Design

- Cost efficient and durable uses 304 stainless steel, for durability 316L stainless steel is available and has higher corrosion resistance.

- For easy maintenance works with SIP (Sterilize-in-Place) and CIP (Clean-in-Place) compatibility.

Versatile Power and Voltage Options

- Has an adaptable power system from 110V to 600V and power from 1.5KW to 55KW while being ideally suited with mid-range tasks from 15KW.

- Great flexibility as these voltage options guarantee adaptability worldwide.

Wide Application Range

- Applicable in the food and beverage, pharmaceutical and cosmetics industries as well as in wastewater treatment.

- Effectively manages a diverse range of shear sensitive, abrasive and viscous fluids.

Common Applications

Food & Beverage

Uses FDA compliant materials, prevents contamination and transfers syrup, juices, milk and sauces.

Pharmaceutical & Biotechnology

Great aid in hygienic liquid transfer as well as precise dosing. Complies with strict hygiene requirements.

Chemical & Petrochemical

Handles aggressive chemicals, slurries, and high viscosity fluids. Options for corrosion resistance ensures longevity.

Wastewater Treatment

Competent in the caregiving for sludge, slurries, and wastewater. Achieves savings in operational expenditures due to energy-efficient processes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Power | 15KW |

| Voltage Options | 110V-600V |

| Material | 316L / 304 stainless steel |

| Flow Rate | Dependable upon the application |

| Max Pressure | Up to 20 bar |

| Temperature Range | -20°C to 150°C |

| Viscosity Range | Up to 1,000,000 cP |

| Inlet/Outlet Size | Changeable |

Frequently Asked Questions (FAQs)

1. What type of fluids can a 15KW rotary lobe pump handle?

Low and high viscosity fluids, food, pharmaceuticals, chemicals and even wastewater sludge can all be handled.

2. Is the pump easy to clean and maintain?

Yes, it is fit for sanitary applications due to its support for CIP and SIP cleaning.

3. What is the difference between 304 and 316L stainless steel?

316L Stainless Steel – Exceptional resistance to corrosion which makes it ideal for harsh chemicals and food-grade applications.

304 Stainless Steel – Low-cost usefulness and resistance against corrosion makes this type alloy appealing.

4. Can this pump run dry?

A rotary lobe pump must not be allowed to run dry, as this will be damaging. Running without fluid circulation will cause damage.

5. What criteria should I consider when selecting a voltage and power option?

These may vary from 110V to 600V and 1.5KW to 55KW based on the regional power supply as well as application requirements in order to ensure optimal performance.

Purchase Now Your 15KW Rotary Lobe Pump

For the most efficient and dependable industrial fluid handling system with 15KW of operational power, look no further. Contact us today for customization options and pricing details tailored to your needs.