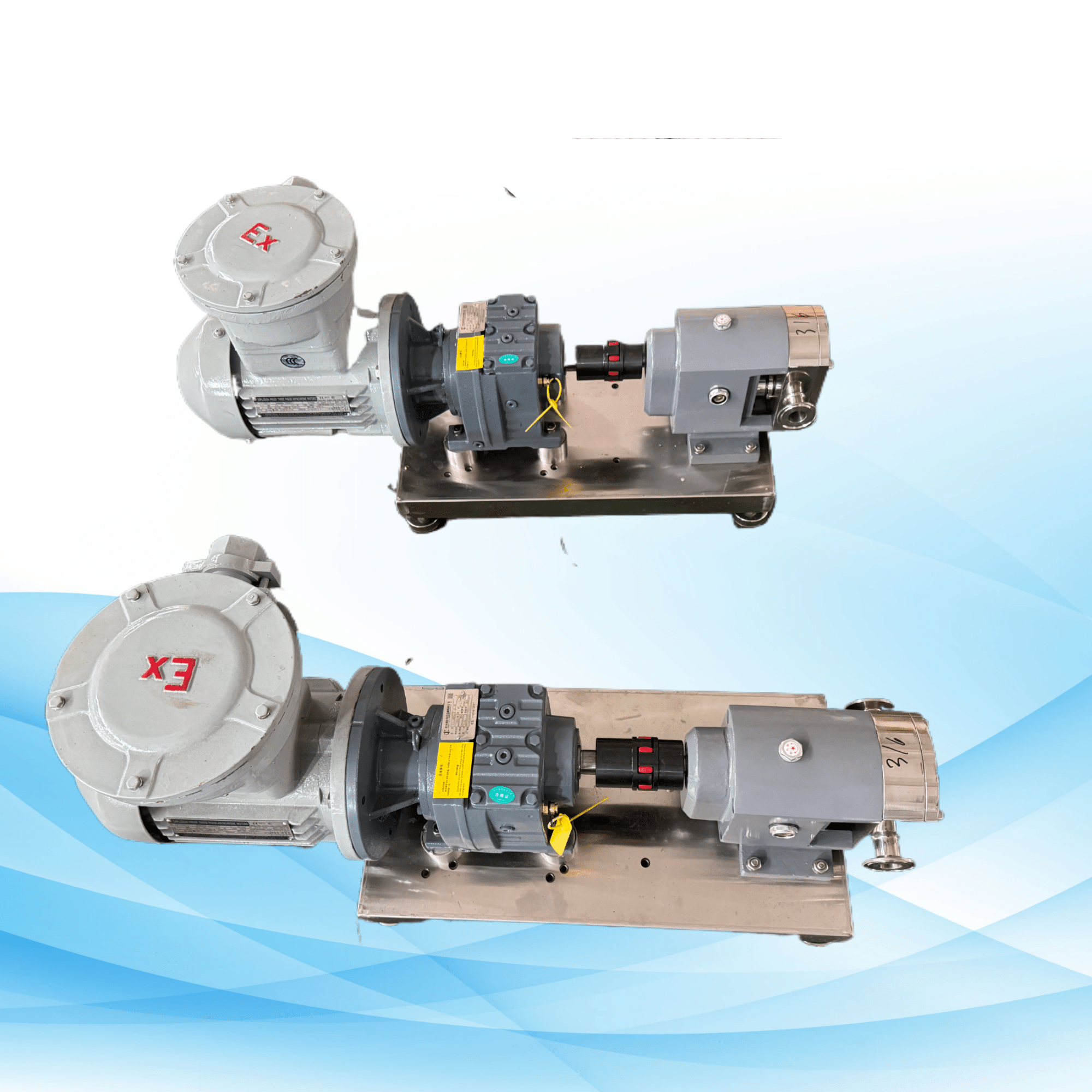

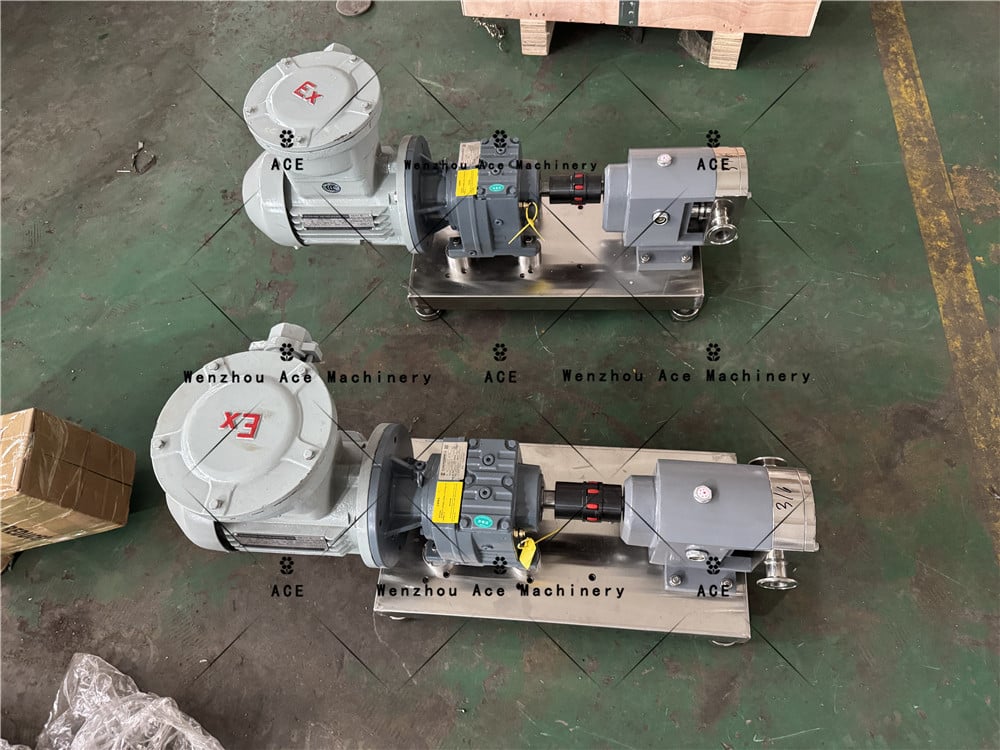

Main Benefits of 2.2KW Rotary Lobe Pump with Explosion Proof Design

Setting New Standards for Safety in Dangerous Areas

This pump has been certified under ATEX, IECEx, and CE standards so it is suitable for use in Zone 1/21 and 2/22 environment. It is made with “explosion proof” motor housing which does not allow for combustion of gases, vapors, or dust that are inflammation. This makes it vital for chemical plants, oil refineries, and even pharmaceutical centers.

Working with a Wide Range of Fluids for Enhanced Materials

- 316L — A stainless steel that has extreme resistance to rust, so it is ideal for aggressive chemical, acids, or saltwater applications.

- 304 — A stainless steel to lower in price for general industrial grade but still able to endure corrosive environment.

110V – 600V Global Voltage Flexibility

The pump can be used with many international power systems, greatly simplifying the use of rotary lobe pump in international bases.

Excellent Operating Efficiency

- Up to 45 m³/h of flow rate for rapid transfer of thick or abrasive media.

- Pressure Capacity: High output in high-demand systems is sustained up to 12 bars.

- Speed Range: Responsibility in controlling the speed of fluids is done in the range of rotatory 200-800 RPM.

Low Maintenance and Sanitary Design

As a result of Capable of Clean-in-Place (CIP) and Steam-in-Place (SIP) the pump has lower downtime in food, beverage and pharmaceutical production lines. Compared to traditional pumps, this one’s non-contacting lobes cause reduced wear, which increases service intervals by up to 30% traditi.

Real World Applications: Where Excellence Meets Pragmatism

1. Oil & Gas Industry

When onshore or offshore, crude oil, diesel and even liquefied gases are safely and spark risk free transferred using the pump. It’s explosion proof designed along with OSHA and API standard compliant makes it ideal for use in the harsh hydrocarbons for 316L construction.

Imagine: Zero safety incidents, no leaks and no downtime when volatile fuels are being transferred in a storage facility which is operational 24/7.

2. Chemical Manufacturing

Polymer melts, acids and solvents can be handled with no confidence concern. Even sulfuric acid or chlorine based compounds qualifies for processing when using the 316L variant that is resistant to pitting and crevice corrosion.

Imagine: A chemical plant safely managing batch transfers of high viscosity resins and maintaining worker safety and seamless process integrity.

3. Food & Beverage Production

Syrups, chocolates, and dairy products can be pumped whilst complying with FDA and EHEDG hygiene requirements. There’s no bacterial build up with polished stainless steel surfaces, and CIP compatibility further enhances sanitation.

Imagine: A dairy facility with effortless switching between products and robust hygiene protocols maintained even during the quick cleaning cycles.

4. Wastewater Treatment

These pumps clear greases, sludge, and abrasive slurries without risk of clogging in hazardous confined spaces. The wear-resistant lobes aid unclogged pumping in high solid environments.

Imagine: A municipal treatment plant that operates smoothly during peak loads, reducing yearly maintenance costs by 20%.

5. Pharmaceutical & Biotechnology

The transfer of sterile fluids and viscous biologics without contamination risk is easily done. GMP requirements are satisfied with the pumps leak-proof seals and sanitary design.

Imagine: A biotech lab that produces vaccines with zero cross-contamination, thanks to precision fluid handling, enabled by advanced technology.

Technical Specifications at a Glance

- Motor Power: 2.2 KW (3 HP)

- Seals: Dual mechanical seals or lip seals, made of PTFE or Viton.

- Protection Rating: Dust and waterproof IP65 certified.

- Voltage Options: Custom 110V, 220V, 380V, 480V, 600V

- Temperature Range: Extended request, ranging from -20°C to +140°C.

- Port Sizes: DN25 to DN100 with flanged, tri-clamp, or threaded connections

Corrective Action: Addressing Primary Customer Issues

Q1: Is it possible that this pump could handle fluids containing suspended solids?

Certainly. This If pumps construction is best is suited for food and wastewater applications where particulates are present because the rotary lobe design can tolerate solids up to 15 mm in diameter.

Q2: Can customization be done for non-standard voltages or materials?

Definitely. We provide customization for materials including Hastelloy or titanium alloys, which are used for more specialized industrial applications.

Q3: How does the explosion proof mechanism function?

The motor is enclosed in a flameproof case which will contain all internal sparks whilst controlling temperature to avoid surface overheating.

Q4: What is the expected service life of this pump?

The pump can last around 8–10 years, and sometimes longer, given it is maintained properly even with 24/7 operations.

Q5: How easy is it to obtain spare parts?

Yes, these parts can be obtained easily. We grant international access to OEM parts, which helps in getting the repair done faster.

Defending This Pump’s Superior Competitor Positioning

- Future-proof construction: designed with the flexibility for 4.0 industry integration for remote observation and predictive maintenance.

- Savings on energy: lowering the rotor power consumption by as much as 15% in comparison to traditional models.

- Ensured compliance: advance certification for global markets moves the procurement process faster.

Take Action: Protect Your Industrial Operations Now

Maintain safety and efficiency with the 2.2KW explosion proof rotary lobe pump. It is not merely an equipment purchase, but strategically enhances your facility productivity and compliance standards.

What Is To Be Done:

- Engage With Our Engineers: Claim your complimentary application evaluation to design the best fit pump (construction, electrical output, gaskets).

- Schedule A Test: Evaluate the pump’s function with your custom media.

- Submit Your Purchase: Enjoy the 24-month warranty and expedited worldwide delivery.