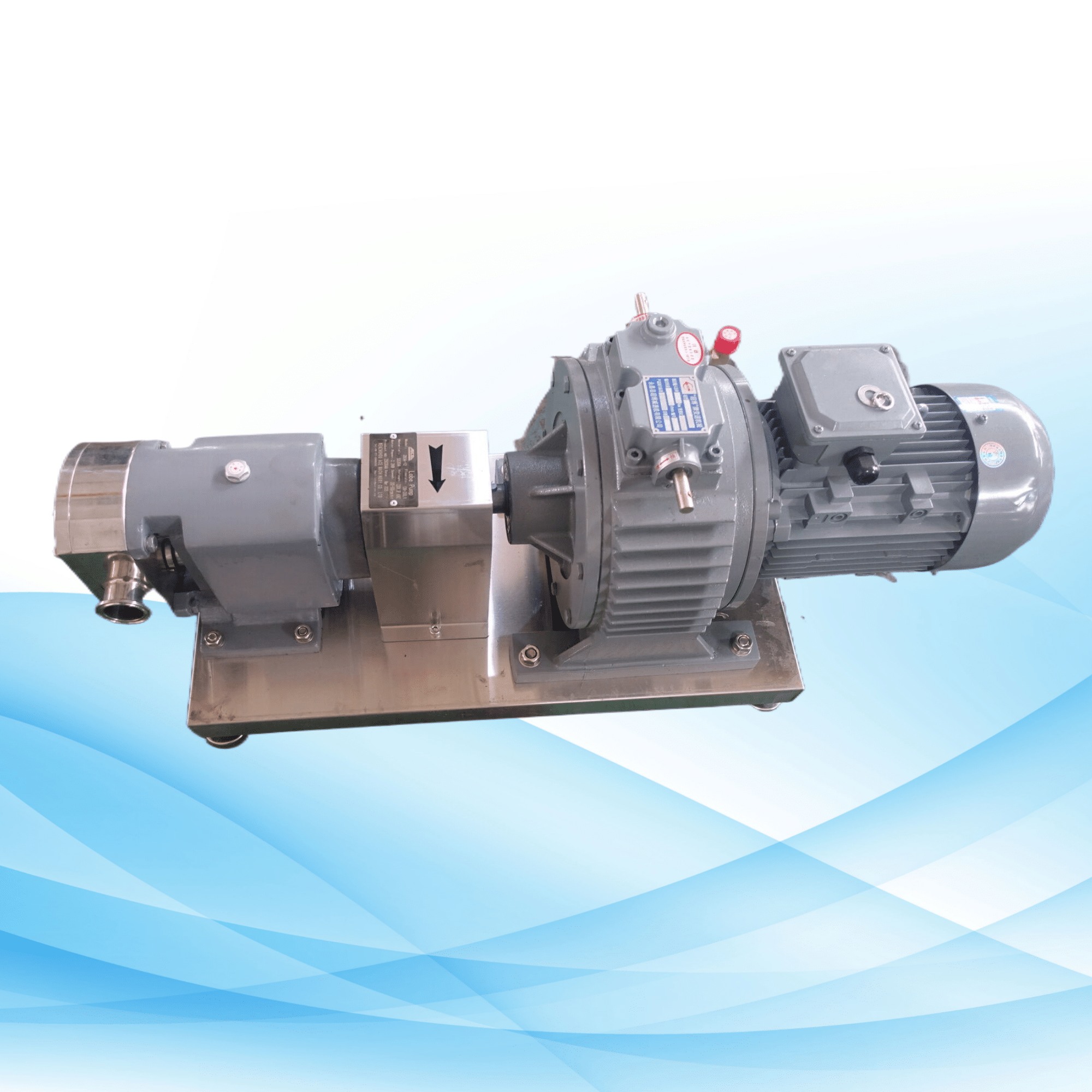

Important Technical Specifications

- Power: 2.2KW (3HP)

- Flexible Voltage: 110V to 600V (single or three-phase)

- Materials: 316L or 304 stainless steel

- Flow Rate: Up to 60 m³/h (varies by viscosity)

- Pressure: 12 bar (max)

- Hygiene Certification: EHEDG, FDA, 3-A compliant

- Temperature: -20°C to 140°C

- Seals: Double mechanical seals or lip seals (optional)

Why Use the 2.2KW Sanitary Rotary Lobe Pump?

1. Unmatched Smoothness

With crevice-free interiors and CIP/SIP compatibility, the polished pump prevents bacterial growth. It delivers non-pulsating smooth flow that preserves the product’s structural integrity, perfect for shear-susceptible fluids such as cream, dairy, or vaccines.

2. Arms of Versatility

The pump’s gentle lobe rotation ensures effective pumping without damaging particles. From high-viscosity chocolate to abrasive cosmetic slurries, the pump provides consistent performance no matter the fluid visited.

3. Global Voltage Compatibility

Use worldwide without worry (110V-600V with voltage customization), no external transformers required, simplifies integration with other systems.

4. Corrosion-Resistant Construction

Select from 316L stainless steel (highly resistant to acidic/chloride environments) or 304 stainless steel for a more economical option, both compliant with food-grade standards.

Real Life Applications & Use Cases

1. Food & Beverage Production

- Dairy Processing: Shear-free transfer of yogurt, milk, or cheese curds, with no separation of curds.

- Sauces & Condiments: Particulate suspension for ketchup, dressings, or jam without shearing texture.

- Beverage Filling: Juice, wine, and liquid sweetener filling with controlled foam-free transfer and precision.

Customer Scenario: A dairy plant using this rotary lobe model avoids 20% product waste after installing this rotary lobe model which enables smoother curd transfer and minimization of maintenance downtime.

2. Pharmaceutical & Biotech

- Active Pharmaceutical Ingredients (APIs): Safe transfer of sterile solutions or viscous gels.

- Bioreactor Harvesting: Gentle media extraction to maintain cell viability.

Customer Scenario: Vaccine production is streamlined at a biotech facility by plugging the pump into a closed-loop system which meets FDA audit standards for cleanliness and traceability.

3. Cosmetics & Personal Care

- Lotions & Serums: Stability of emulsions in advanced skincare production.

- Toothpaste & Creams: Silica or abrasive exfoliants are actively managed without wear on the lobes.

Customer Scenario: A cosmetics manufacturer removes problems related to air ingress, leading to 99.9% homogeneity in the production of luxury moisturizers.

4. Chemical Processing

- Sanitary Chemicals: Ensure safe transfer of sanitizing fluids, acids, and CIP chemicals.

Material Customization & Voltage

- 316L Stainless Steel: Best suited for highly corrosive or high-purity sectors (e.g., saline solutions, citrus juices).

- 304 Stainless Steel: Economically priced and suitable for non-corrosive surroundings (e.g., vegetable oils, syrups).

- Voltage: Set regionally, e.g., North America 110V/60Hz and Europe 400V/50Hz.

FAQ Section

Q1: How often should a pump be cleaned for sanitary applications?

A: In food/pharma use, daily CIP cycles are recommended. The quick-disassembly design of the pump permits complete sanitation within thirty minutes.

Q2: Can it manage solids within liquids?

A: Yes. The pump can manage particles with a diameter of up to twelve millimeters, including fruit pulps and pharmaceutical granules.

Q3: Is the 316L material outrageously overpriced?

A: In fluids containing acids, salt, or chlorides, 316L would have better longevity and resistance towards corrosion along with passing hygiene checks.

Q4: Do you have models certified ATEX for explosive environments?

A: Yes. For pumps designated for Zone 1/21 hazard areas, get in touch with our team.

Q5: How much time is required for custom voltage configurations?

A: Custom voltages have a lead time of about 3 to 4 weeks. The standard configurations ship in a time frame of 7 to 10 days.

Conclusion

This 2.2KW sanitary rotary lobe pump is the first of its kind in the hygienic fluid handling industry, integrating precision engineering with rotary lobe pump design to redefine efficiency. Its use in beverage lines and vaccine production scaling utilizes advanced engineering design aiding in compliance, thus ensuring a quick return on investment.

Do you want to advance your process?

Strategically, we can be contacted for a performance trial without any investment required, or a performance trial quote can be placed along with contacting us. The pump is tailored by our engineers optimally using the seals, voltage, and material for any application.