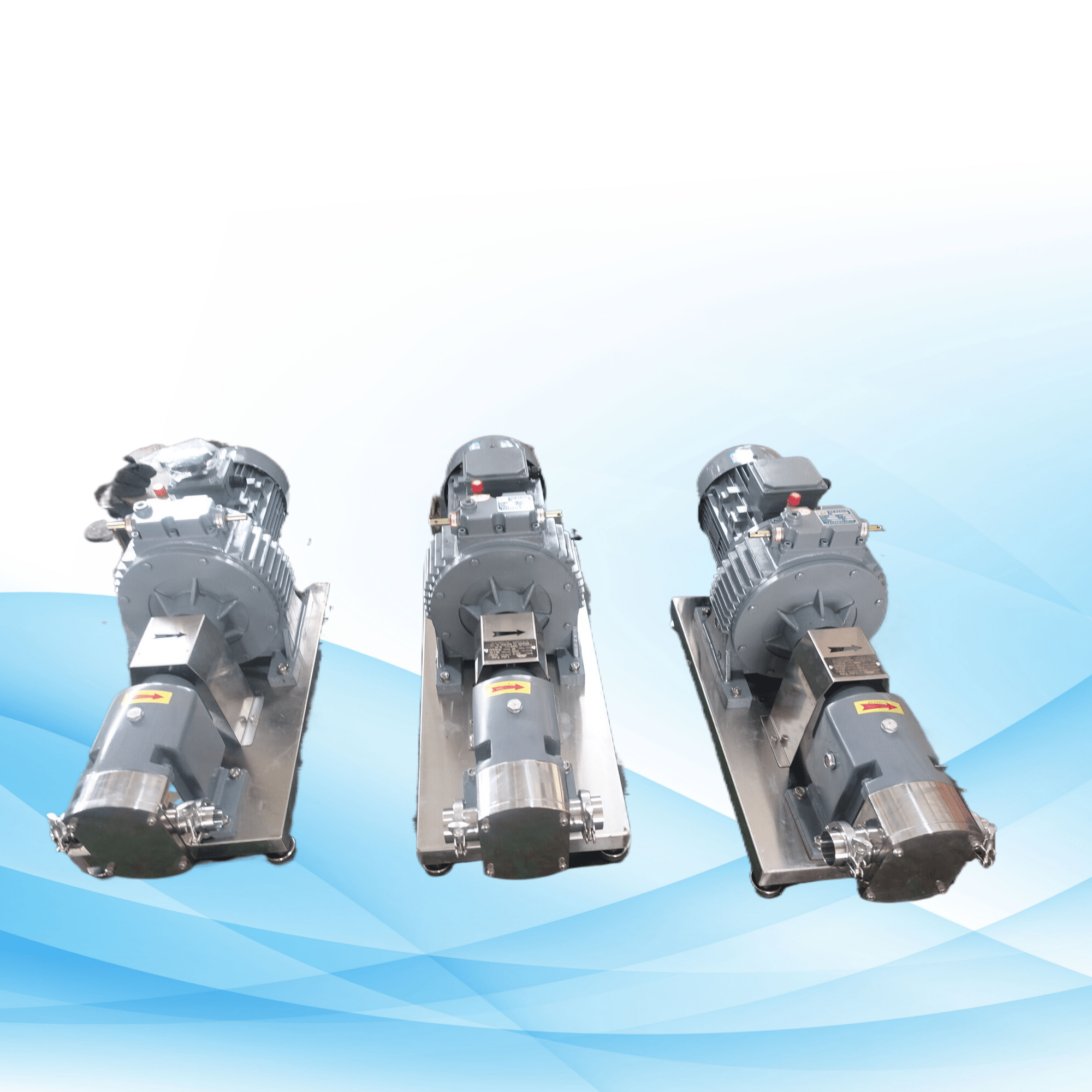

Key Features & Benefits

Efficient & Versatile Motor

A robust motor rated at 4KW powers the pump, making it suitable for many applications. Its energy-saving design adds to its versatility.

Optimized Hygienic Design

Crafted from stainless steel (316L and 304), the pump is hygienic and minimizes the risk of contamination.

Flexible Voltage Options

Custom voltage ratings allow it to operate at 110V to 600V. This feature makes it suitable for many countries and their respective power supply systems.

Gentle Product Handling

The design of the pump lobe results in low shear forces being applied to sensitive fluids such as creams, spoonable syrups, and dairy suspensions, thus safeguarding their structural properties.

CIP & SIP Compatibility

Standards of hygiene are easily maintained with clean-in-place (CIP) and sterilization-in-place (SIP) compatibility of the system.

Durability & Corrosion Resistance

This pump is designed for long hours of operation and aggressive cleaning solvents due to its stainless steel construction and advanced sealing systems which offer unparalleled protection against corrosion.

High Efficiency & Low Energy Consumption

Maintained flow rate and pressure, while reduced energy expenditure due to optimized internal structure.

Applications & Use Cases

Food & Beverage Industry

- Pumping of yogurt, milk, and cream while reducing aeration to a minimum.

- Pumping of juice, syrup, and sauce while maintaining the flavor and texture.

- Processing chocolate, honey, and other viscous materials without damaging them.

Pharmaceutical & Biotech Industry

- Transfer of gel-like medications, vaccines, and liquid drugs without risk.

- Ideal for clean environments that need fluid transfer without contamination.

- Works with personal care items like lotions and cosmetic creams.

Chemical & Industrial Applications

- Transfer of sensitive and corrosive chemicals in controlled conditions.

- Pumping paint, lubricant, and adhesive at a constant rate.

- Handling of emulsions and solvents that require low shear during the processing.

Technical Specifications

| Specification | Details |

|---|---|

| Motor Power | 4KW |

| Voltage Options | 110V / 220V / 380V / 440V / 480V / 600V |

| Material Options | 316L Stainless Steel / 304 Stainless Steel |

| Flow Rate | Dependent on the application and viscosity of the product. |

| Max Pressure | Depends on application; usually 10 bar max. |

| Temperature Range | Suitable for a wide range of operating conditions |

| Seal Options | Mechanical Seal, Lip Seal, O Ring Seals |

| Hygienic Standards | FDA, 3A, EHEDG compliant |

Why Choose Our 4KW Hygienic Lobe Pump?

Reliability, efficiency, and compliance with standards are critical considerations when receiving a hygienic lobe pump.

Our 4KW hygienic lobe pump is the pinnacle of industrial engineering and design. Its energetic properties work seamlessly across diverse industrial applications. From the smooth transfer of dairy to pharmaceuticals and even highly viscous fluids, this pump offers unparalleled efficiency and durability.

Frequently Asked Questions (FAQs)

1. What distinguishes a hygienic lobe pump?

A hygienic lobe pump is extremely sensitive to sanitation standards; hence the material used, 316L or 304 stainless steel, guarantees that there will be no cross-contamination of fluids as it is FDA and EHEDG certified.

2. Is this pump adept at managing fluids of high viscosity?

Of course! With versatility being the foundation of the 4KW hygienic lobe pump, it is equipped to handle everything from water to highly viscous materials like honey, creams, and even adhesives.

3. Is this pump capable of being utilized in high temperature applications?

Yes, this is possible as it can bear the brunt of many changing temperatures; however, it is wholly dependent on the seals chosen alongside the requirements of the process.

4. What is the procedure for maintenance?

Maintenance and the bearing of the cleaning load of this unit are exceptionally simple, as it is CIP (Clean-in-Place) and SIP (Sterilization-in-Place) compatible.

5. Are there changes in pump specifications available?

Certainly! Configuration of 110V-600V voltage, sealing openings, and even the type of stainless steel, 316L or 304, can all be changed to best fit the customer’s operational requirements.

Today, Place an Order For Your 4KW Hygienic Lobe Pump

Buy our 4KW hygienic lobe pump today, and integrate it into your fluid processing apparatus to receive unparalleled efficiency and total sanitation. Get in touch with us today if you need a customized quote or to specify other needs!