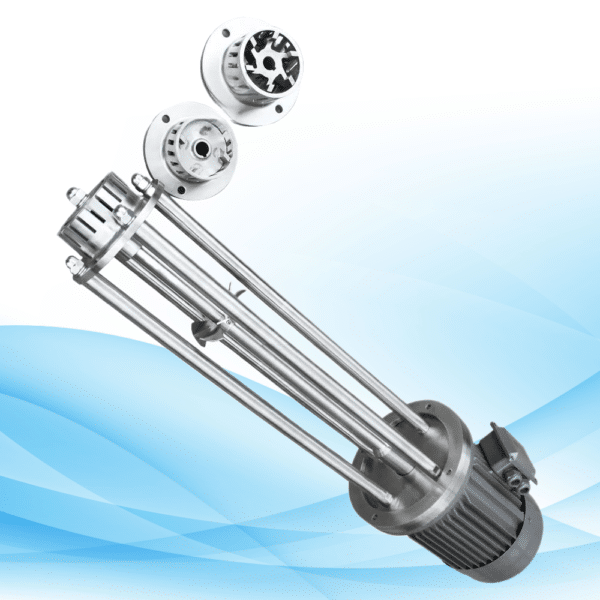

Robust Power & Precision Performance: 7.5KW High Shear Mixer Advantages Emphasis

With the power capability of 0.75KW to 55KW as well as giving unrivaled shear strength in breaking down particles and creating blends with the aid of dissolving pumps, high precision and power are guaranteed. The 7.5 KW blade model is best applied in medium and large production lines, as it efficiently balances its energy use with its processing capacity.

Voltage Flexibility for Global Compatibility

These blades are best suited to mechanically diverse industrial structures as they allow switching of voltages from 110V to 600V, making them accepted in different parts of the world. This means that if your facility is based in North America, Europe, or Asia, you would significantly save costs that would be incurred in retrofitting.

Premium Mechanical Properties

316L Stainless Steel

Stainless steel type 316L is best suited for extremely aggressive chemical processes, pharmaceutical formulations, or saline solutions because of its superior corrosion resistance.

304 Stainless Steel

Stainless steel type 304 is a more affordable option for food-grade applications like the processing of dairy products or mixing non-corrosive substances.

Optimized Blade Geometry

The rotor-stator design causes intense mechanical shear, which results in processing time being 40% less compared to other mixers. Along with time savings, the system achieves an increased throughput while decreasing operational costs.

Applications: Where the 7.5KW High Shear Mixer Blade Excels

Biotechnology and Pharmaceuticals

- Homogenization of active pharmaceutical ingredients (APIs).

- Emulsion formation for creams and cosmetic injectables.

- GMP compliance is vastly aided by easy-to-clean surfaces which are contamination-resistant.

Food and Beverage Production

- Sauces alongside dairy product emulsification.

- Liquid powder dispersion like protein shakes, flavoring, and more.

- Condiments and spreads requiring a smooth consistency.

Chemicals and Coatings

- Dispersion of nano-sized particles for paints and adhesives.

- Polymers, resins, and lubricants blended rapidly.

- Agglomerates of pigment slurries lessened.

Cosmetics and Personal Care

- Stabilization of lotions, serums, and sunscreen formulations.

- Fragrance and vitamin infusion without viscosity loss.

Technological Attributes

| Parameters | Specifics |

|---|---|

| Power Range | 0.75KW–55KW (with 7.5KW model emphasized) |

| Voltage Options | 110V, 220V, 380V, 415V, 480V, and 600V |

| Material | 316L or 304 stainless steel (subject to change with further requests) |

| Blade Diameter | 100mm–500mm (model dependent) |

| Speed Range | 0–3,000 RPM (can be modified depending on viscosity & phase requirements) |

| Temp. Operating | -20°C to 150°C (accessory jackets for cooling/heating available, augmenting versatility) |

Why Choose Our High Shear Mixer Blades?

- Reducing Downtime: Quick blade replacement achieved via modular design.

- Flexibility: In-batch or inline systems integration enables versatile scaling.

- Certifications: In compliance with CE, ISO, and FDA for regulated industries.

FAQs: Addressing Vital Customer Concerns

How Power (KW) application should I choose?

Determine the viscosity of the materials versus blade power versus batch size, and you’ll achieve your ideal results. The 7.5KW model is best suited for 500–2,000L batches.

Which is better, 316L or 304 stainless steel?

316L offers better resistance to corrosion with harsh chemicals, while 304 would suit food or non-corrosive substances.

Is it possible to customize blade dimension?

Custom solutions offered for rotor-stator, shaft length configurations, or mount systems makes it possible.

What maintenance needs doing?

Dishwasher-safe materials for sanitary applications suggest regular inspections for seals and bearings.

What are the warranty options available?

Your purchase comes with a 24-month warranty for manufacturing defects. Additional support plans can be purchased to extend coverage.