Product Features and Specifications

Voltage Range

Relatively, the high shear mixer pump can be modified to operate on two voltage extremes, meaning low voltage alternating and high voltage alternating systems. As such, the unit can be positioned within alternating current systems around the globe from 110-volts to 600-volts. Unit flexibility makes these pumps ideal in all forms and scales of manufacturing processes.

Power Options

The high shear mixer pumps have an accomplished power range that makes them efficient in all manners of operations. Power options ranging from 0.75KW to 55KW are the optimal representations where the pump can withstand both low-range and high-range mixing.

- 0.75KW to 5KW: Efficient in light-duty mixing applications especially when low viscosity liquids need emulsification.

- 5KW to 20KW: Efficient in medium-range duties in the production of creams, lotions, and moderate viscous mixture blends.

- 20KW to 55KW: Suitable for processes such as adhesives, pastes, or any other highly viscous or concentrated suspension processes that are heavy-duty.

Material of Construction

These types of pumps are made of stainless steel, either ss304 or ss316l. These materials prevent and endure corrosion and enhance the durability of the pump, which is important for corrosive industries dealing with chemicals, food-grade products, or pharmaceuticals.

Flow Rate and Capacity

High shear mixer pumps, depending on their power rating and application, can handle any flow rate between 5 liters to 5000 liters per hour. This capacity is quite accommodating for both batch production and continuous production lines.

Shear Rate

The mixer pump generates a shear rate of up to 3000 rpm enabling shearing of particles or droplets to micron and even nanoscale size for the purpose of uniform dispersion within the mixture.

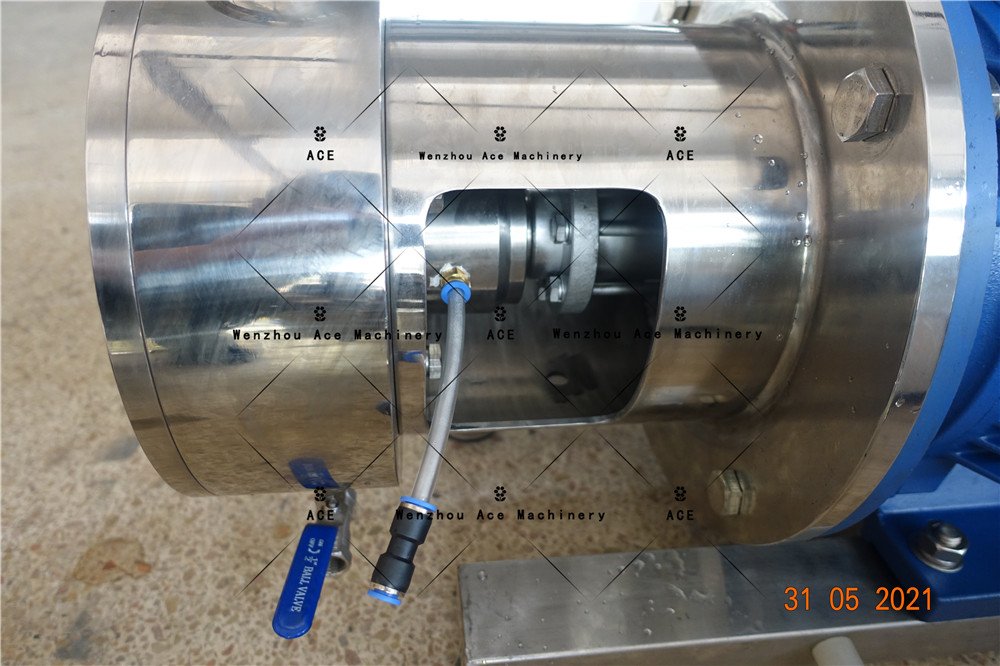

Seal Options

High shear mixer pumps include a mechanical seal to withstand high-pressure processes and a lip seal for processes that require less maintenance frequency to enhance operational life and efficiency in difficult working conditions.

Applications of High Shear Mixer Pumps

There are numerous high shear mixer pump applications in different fields: the versatility of the handled materials and processes is always distinctive for them. Some of them are:

Building and Construction Industry

High shear mixer pumps are commonly used for making thick slurries since they break down clogs and lumps present during construction. Additionally, these mixers help self-level thick liquid polyurethanes used as construction adhesives to eliminate air bubbles, thus ensuring structural and aesthetic perfection.

As color uniformity is a crucial aspect for tensile and other mechanical strength, high shear mixers are used for mixing polymer paints and dyes perfectly while achieving better dispersion of the paints in water.

Pharmaceutical Industry

High shear mixer pumps are critical in the production of suspensions, ointments, pastes, gels, and creams in the pharmaceutical field. They provide particle size distribution which is important in making quality and even products.

Food & Dietary Supplement Industry

In the food and dietary supplement industry, high shear mixer pumps are vital as they blend very viscous and non-water-miscible liquids such as gums and caramel color. There is better homogenization and dispersion of emulsions, thus high uniformity in the end product. Most importantly, high shear mixer pumps also suit adhesion processes for sauces, beverages, and spreads.

Cosmetic Industry

Cosmetic manufacturers use high shear mixer pumps because they emulsify gels, lotions, and creams. These devices make high-quality products as they have the ability to create a smooth texture, which is essential in cosmetic products.

Chemical Industry and Ink Production

These devices also have high mixer shear to emulsify water and paints, making uniform particle distribution possible. As a result, paint and emulsion manufacturers can greatly depend on high shear mixer pumps.

Frequently Asked Questions (FAQs)

How does a high shear mixer pump differ from a common pump?

The difference between a high shear mixer and a standard pump is that a high shear mixer does not just transfer a liquid from one location to the other but also cuts and mixes that liquid which is performed with high-speed shear action. Regular pumps move fluids only, but quite simply without blending, emulsifying, or mixing.

Is a high shear mixer pump suitable for high viscosity materials?

Yes, it is. The design of a high shear mixer pump is meant to handle variations in viscosity, including highly viscous materials such as pastes, gels, and adhesives.

What is the centrifugal force for a high shear mixer pump?

High shear mixer pumps vary in power from 0.75KW to 55KW, which means they can be used for light, medium, and heavy-duty tasks depending on the specific requirements of the industry.

Is it possible to alter the voltage of the high shear mixer pump?

Yes, the pump may be built to operate between 110V and 600V enabling it to be used in different countries and power arrangements.

How frequently does the pump need to be maintained?

High shear mixer pumps are quite strong and durable, however, factors such as the seal type or the raw materials used in operations affect the maintenance frequency. Usually, mechanical seals require less maintenance than lip seals.

Which industries benefit the most from using high shear mixer pumps?

The following industries benefit the most: pharmaceuticals, cosmetics, food and beverage, chemicals, and adhesives since they can take advantage of the precision of the high shear mixer pumps.

Conclusion: Why Should You Buy Our High Shear Mixer Pump?

If your company needs exceptional mixing, blending, and emulsifying, our high shear mixer pump fits various requirements. Our voltage output ranges from 110V to 600V while power output per unit ranges from 0.75KW to 55KW allowing it to fit a variety of industrial applications, guaranteeing precision control, optimum operation, and dependability.

Regardless of whether your specialization is in bakery, food and other edibles, cosmetics, or chemicals, our high shear mixer pumps would dramatically enhance your workflow as they will increase efficiency and allow for quick production times as well as uniform consistency among mixtures.

You may want to reach our team today for further details on our high shear mixer pumps and which model best meets your requirements. We have a team of professionals who will help you choose the right model for better performance of the production line and other components. Wait no more, improve your operations with our cost-effective yet efficient high shear mixer pumps.