Key Features and Advantages

Exceptional Durability

Users will be pleased to learn that the High Shear Dispersion Mixer professionally constructed from the most expensive stainless steel options, 316l and 304, is corrosion and wear resistant. The reliable construction in which the High Shear Dispersion Mixer uses also ensures that there is durability alongside optimal performance, as the materials are of good quality. As such, even the most severe mixing tasks can be performed, and perfect reliability can be achieved for prolonged production periods.

Customizability of Power Options

When it comes to the High Shear Dispersion Mixer, one of the most interesting features we have is the power range. This mixer can be used for a wide range, starting from 1.5KW up unital 55 KW. We have options for power capacity lab use specimens up until large industrial batches. Hence, you’ll have the power necessary to get the right consistency time after time.

Varied Voltage Ranges

This mixer has been constructed so that it can easily be incorporated into any operational system and comes with an allowed voltage threshold of 110V to 600V. This flexibility ensures that each n every High Shear Dispersion Mixer can be ordered across the world and installed on both standard voltage and high voltage systems.

Use of Enhanced Shear Technology

The High Shear Dispersion Mixer employs high-shear mixing technology to disintegrate the components at a molecular level. This yields more micro emulsions and smoother blends which disperse faster of more complicated formulations such as emulsions and Suspenders. Be it oils, creams. Paints or any other item being mixed expect optimum usage of this mixture.

Novel Approach to User Oriented Efficiency

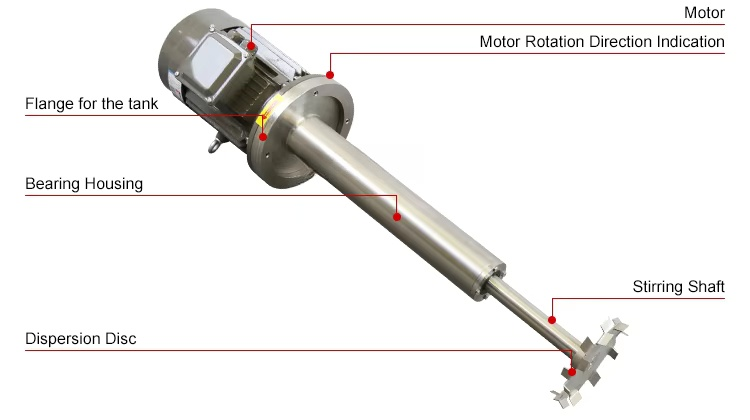

An efficient control panel is available and thus in conjunction with the High Shear Dispersion Mixer, the user is tasked with less control while commending the output. The low-sloped ceiling set up ensures quick rotter and stator modifications while delivering customization options with different speed settings. In sum, the device guarantees optimization on a per-need basis with regard to the application being polished. The aforementioned elements are sufficient in reducing rotor and stator complexity while enhancing performance on a powerful motor. As a direct consequence, the time needed for several mixing stages is cut down.

Reducing Losses

For the cost that it entails, High Shear Dispersion Mixer certainly takes an edge and offers excellent quality. Mix times tend to drop and efficiency goes up, thus investment installation goes down, which makes businesses unable to ignore this as it has productivity and economic incentives built within.

Real Life Applications

Slicing through the fog of ambiguity that surrounds High Shear Dispersion Mixers, the devices are versatile and can be applied across immense industry sectors, such as:

- Food & Beverage Industry: Widely used in the making of sauces, dressings, soups, and drinks, as it provides an amalgamated end product.

- Pharmaceuticals: Assists in combining various liquids and powders, emulsifying diverse active pharmaceutical ingredients, making them transparent and easier to use within gels, creams, and ointments.

- Cosmetics and Personal Care: Suitable within the lotion industry as it splits the various ingredients while stabilizing the mix, allowing the lotion to be easier to use and apply.

- Chemicals: Effective in mixing paints, coatings, inks, adhesives, and other mixtures where proper blending of pigments and other variants is required, thus ensuring optimal performance for the end product.

- Biotechnology: Applicable in homogenizing cells, extracting proteins, and in various other research related lab work which require the usage of shear mixers.

By opting for the High Shear Dispersion Mixer, you are picking an apparatus which ensures that quality is maintained, stability is guaranteed, and each mix is perfected, thereby increasing the overall output of the production.

Customization Options

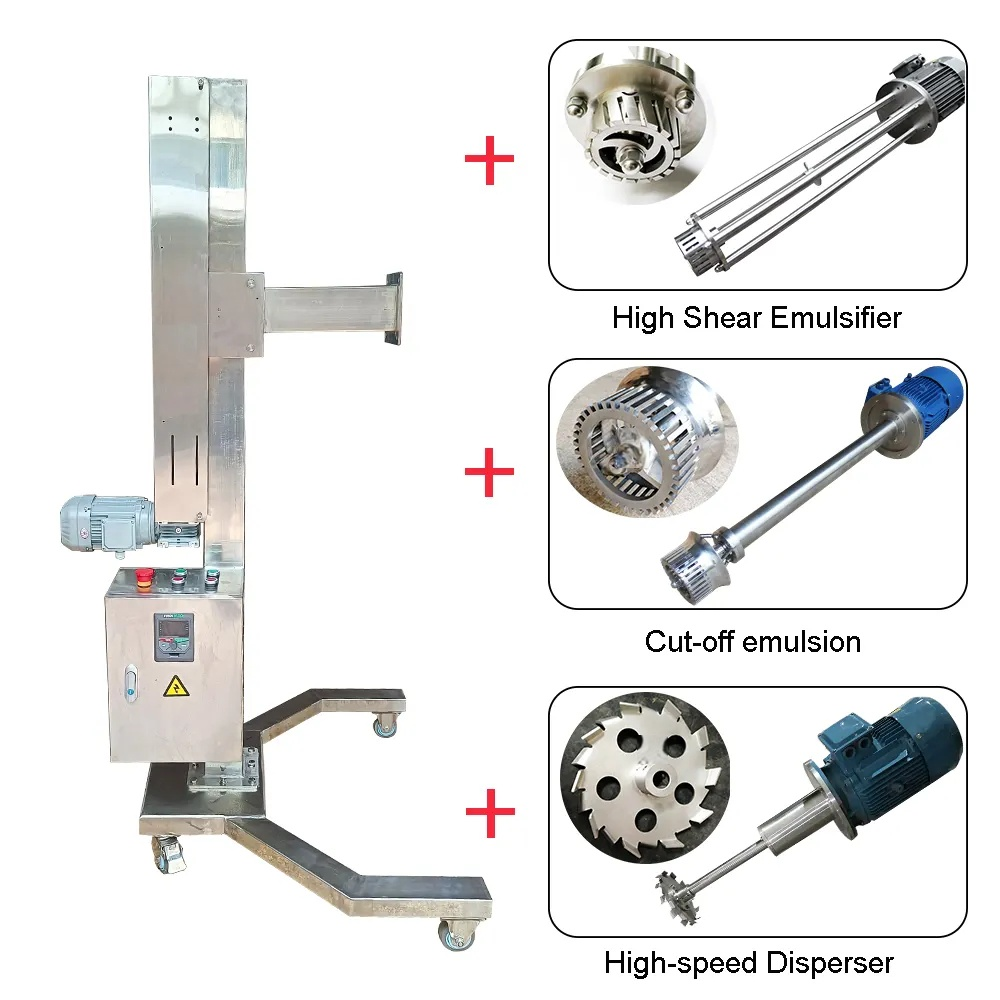

Each application requires a different set of features, and our High Shear Dispersion Mixer is equipped with custom features for such requirements:

- Material Choices: 316L stainless steel for corrosive environments and 304 stainless steels for general use, each providing exceptional anti-rust and wear properties, ensuring mixer longevity.

- Rotor and Stator Configurations: Design the rotor and stator configurations based on shape and composition of the material used, ensuring higher efficiency and performance.

- Motor Power: Customizable from 1.5KW to 55KW

- Voltage: Available in 110V, 220V, 380V, & 600V with a custom option

- Materials: Corrosive environment suitable 316L stainless steel or general-purpose 304 stainless steel

- Speed Range: Adapts up to 3600 RPM

- Max Capacity: Offers customization in accordance to both power and material requirements

- Control System: Digital control panel featuring speed and shear adjustment

Technical Specifications

Commonly Asked Questions

Q1: Are there any particular industries where the High Shear Dispersion Mixer is utilized?

A1: The High Shear Dispersion Mixer is a multipurpose machine that is used in a wide range of industries including food and beverage, pharmaceutical, cosmetic, chemical, and biotechnological. It is suitable for precisely mixing, emulsifying and dispersing various applications.

Q2: Is it possible to utilize the mixer for both small and large volumes of production?

A2: The High Shear Dispersion Mixer however opens up a vast opportunity for versatility with its power range of 1.5KW-55KW allowing for small laboratory batches and large industrial mass scale production.

Q3: Is there a recommended approach on selecting 316L or 304 stainless steel to work with?

A3: For highly corrosive environment either acid or alkaline materials are to be worked in, then it is recommended to utilize 316L stainless steel. 304 stainless steel is the best for general purpose materials as it is highly durable.

Q4: Is it possible to customize a High Shear Dispersion Mixer?

A4: For certain! Our customization encompasses a plethora of features such as power ranging from 1.5KW to 55KW, voltage adjustments between 110V to 600V, and rotor/stator adjustments. Such flexibility allows the mixer to be customized to suit an individual’s unique mixing requirements in the best possible manner.

Q5: What are the required services for the High Shear Dispersion Mixer?

A5: The extensiveness of cleaning the rotor and stator, visual inspection of motors and other components for any unusual signs of wear and damage, comprises regular maintenance. Conducting these inspections on a regular basis will prolong the longevity of the mixer while ensuring its enhanced performance.

In conclusion, it is reasonable to argue that the High Shear Dispersion Mixer is an excellent investment in terms of enhancing the speed and efficacy of your production process. With its high shear mixing technology which guarantees a single model can perform multiple tasks it has an ability to cater to diverse industries and most importantly it is user-friendly with a constructive design. If your company is involved with the making of food products, pharmaceuticals, or chemical substances then you will find the High Shearer Dispersion Mixer to be your go-to item in all your mixing activities.

This is an opportunity you can’t ignore; step up