Key Features and Advantages of High Shear Emulsifier Mixer

1. Durability and Longevity

This mixer is also highly durable due to being built with strong materials such as 316L and 304 stainless, which explain as to why high shear emulsion mixers can last for so long. With a durable steel body shield enables this mixer to be both resilient against rust and unexpected manual damages, ensuring that it shall proceed to perform optimally as well as reliably during even rough conditions.

2. Custom Power Options

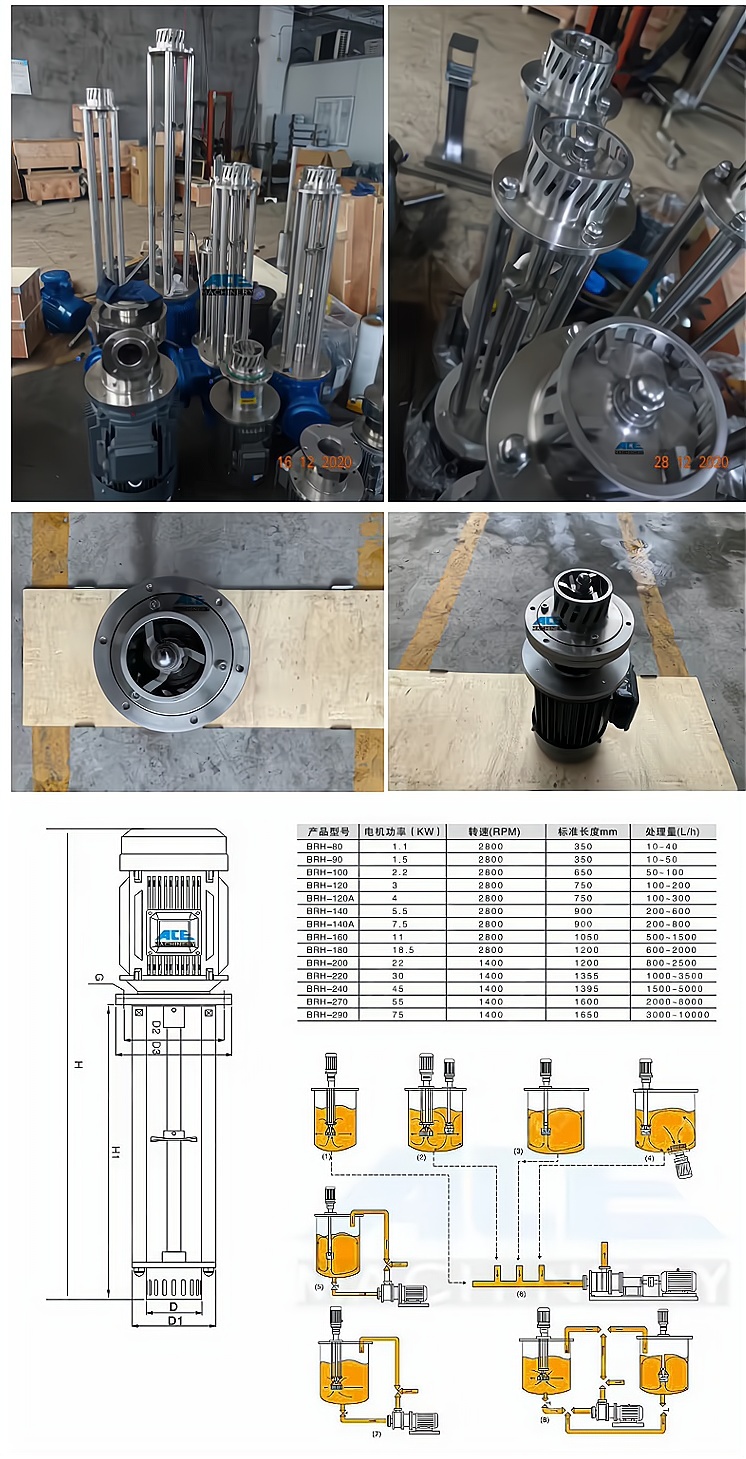

Ranging from 1.5KW to 55KW, our High Shear Emulsifier Mixer can be customized according to the sector’s needs. The mixer can work for both small batches and very large ones so users can opt for the desired power they see fit. It also supports a wide voltage range, from 110V up to 600V allowing the emulsifier to be used on multiple systems globally.

3. Outstanding Mixers Due to Optimal Design

Ensuring the emulsions require fine dispersion, this emulsifier mixer has a lot to offer in terms of high shear mixing. Due to the unparalleled speed of the rotor and stator that are designed to pulverize the ingredients into the smallest grains possible that allow for the creation of foam that emulsifies, is homogeneous and even.

4. Great Economical Returns and Enhanced Efficiency

The High Shear Emulsifier Mixer drastically enhances productivity and provides businesses with long-lasting profits, especially those looking for ways to cut costs and maximize their gains. Not only this but the emulsifier mixer also greatly reduces energy costs with its exceptional power management and mixing capabilities.

5. Making Maintenance and Cleaning as Easy as Possible

The engineers who created the High Shear Emulsifier Mixer focused on the retrofitting ease of the mixer. It reduces the interruptions during the work as its components are designed for ease of cleaning and servicing. To make the equipment ready for work at all times, its configuration allows the operators to carry out the basic maintenance tasks effortlessly.

Uses of High Shear Emulsifier Mixer

High Shear Emulsifier Mixers can be used in a variety of businesses and industries. A few but relevant examples of these are just exactly some of the more important sectors that bear its benefits.

1. Food Industry

Emulsions in food production are crucial in the manufacture of emulsified products since they help produce products with a smooth and uniform texture such as mayonnaise, salad dressings, sauces, and beverages. Processes for making refined oil products of high emulsification can mix oil, emulsifier, fat, and water together and disperse them into a stable high quality oil-in-water emulsion. The device can be used in several applications because it can handle high viscosity and low viscosity materials.

2. Pharmaceutical Industry

Even in the pharmaceutical sector, emulsification of creams, ointments, gels, and suspensions is required to be both accurate and active. Having the ability to mix emulsions of different physicochemical properties and make them stable meets the requirements of the strict standards placed on pharmaceutical products. High Shear Emulsifier Mixer provides emulsion and sufficient shear respectively to active components that need to be emulsified for topical or oral applications.

3. Cosmetics and Personal Care

In the cosmetics industry, creams, lotions, and gels are necessary, the blending of their elements has to be done very carefully to provide appropriate texture and skin tolerance and stability. For smooth emulsions for rough cosmetic texture, the High Shear Emulsifier Mixer has been known to meet the requirements of specific organizations. In the manufacture of cosmetics, various ingredients tend to be fragile which ultimately affects the texture of the final product which the consumer expects to be smooth.

4. Chemical Processing

Emulsions in chemical form are quite common in numerous industries such as paint, coating, glue, and lubricant manufacturing industries. Chemical emulsions include oils and water mixed together but separate liquids. These types of emulsions, which are couple of liquids, form mixtures of oil and water. In industrial processes, emulsions such as these are quite common, especially in the creation of chemical formulations. The High Shear Emulsifier Mixer is particularly useful since it mixes every droplet of liquid within the emulsion and does so at extremely high rpm.

5. Biotechnology

The application of high shear emulsification in the biotechnology and related fields, especially in the creation of vaccines, cell cultures and protein formulation, has been propelled by the increase in research in these areas. High Shear Emulsifier Mixer provides extreme precision and control and thus is perfect for the high value-added biotechnology industries that require controlled particle size and emulsions.

The High Shear Emulsifier Mixer is made to suit the particular needs of almost any operation as it has power customization options with power rating between 1.5KW and 55KW. This multipurpose is one of the greatest features as it allows companies to select the most appropriate model in relation to their production criteria. Furthermore, the mixer has a very wide range of supported voltages from 110V to 600V, enabling its use across different locales. After all these customization options, these emulsifier mixers should blend effortlessly into your existing production line.

Stainless Steel 316L and 304 are the two material options available for use in our emulsifier mixer. Both materials are corrosion resistant and possess reasonable level of strength to make sure that the mixer operates effectively for long period of time in unfavorable working environment. In comparison to stainless steel 304, which is good for standard industrial purposes, stainless steel 316L is more suitable for applications in the food, pharmaceutical, and chemical industries because of its corrosive qualities.

Questions Frequently Asked

Q1: Can the High Shear Emulsifier Mixer deal with various ranges of viscosities?

Sure, the High Shear Emulsifier Mixer can emulsify viscous materials as well as low viscosity materials. Its powerful emulsifier design ensures proper emulsification of both high and low shear materials.

Q2: What is the upper limit of the power capacity of the High Shear Emulsifier Mixer?

A selection of the mixer that ranges from 1.5KW to 55KW will always be present therefore, it is ideal to select the correct one that fits according to your production scale.

Q3: Which ranges of voltages can the mixer utilize?

High Shear Emulsifier Mixer offers operating voltage of 110V to 600V to be used within different arrangements of electrical communication around the globe.

Q4: What are the materials that make up the emulsifier mixers?

The specified numerous needs have been met with varying power capacities and allowing to choose between 304 or 316L stainless steel on the high quality stainless steel glue mixer.

Q5: Is the High Shear Emulsifier Mixer tailored for my needs?

Yes, specific needs for your mixing process can be met while customizing its power capacity, the required voltage and what materials to be utilized.

Conclusion: Invest in Efficiency and Quality

The High Shear Emulsifier Mixer possesses the best combination of strength, efficiency, and flexibility. This equipment remains integral in multiple industries due to its ability to produce emulsions that are of equal quality and stabilize. It offers an efficient way in accommodating your specific production requirements due to having adjustable power capacity, voltage compatibility and suitable material choices. In the food, pharmaceuticals, cosmetics, or chemicals industries, the High Shear Emulsifier Mixer provides the best price for emulsified products. For the sake of quality of your products, do not hesitate to purchase a High Shear Emulsifier Mixer because there will be a difference in your production cycle.

What are you waiting for? Increase your emulsification effectiveness by placing an order for your High Shear Emulsifier Mixer.