Material Composition

SUS304 and SUS316L are common materials in the construction of heavy-duty liquid transfer pumps for their ability to withstand humidity, heat, and physical friction. Since the pump consists of stainless materials, the structure tank has advanced into punching of the pump, enabling the construction of tanks that are able to withstand extreme conditions, usually high temperatures and industrial environments. Respectively, an encasement for the pump tube susceptible to strong corrosive chemicals and contaminated erosion is made of SUS304 stainless steel for informative usage.

Motor Options

The pump may be equipped with an ordinary cast iron motor or an explosion-proof motor, depending on the use of the pump. The axis of the explosion-proof motor is made for regions dealing with flammable and explosive substances, ensuring safety according to industrial safety regulations.

Inlet and Outlet Configurations

Due to the fact that it is a liquid transfer pump, which can be incorporated into any piping network, it has a wide variety of inlet and outlet arrangements for easy fitting.

Fast Spin Collar Type

A quick fitting designed for fluid transfer applications employing frequent assembly and disassembly in a short time span.

Internal and External Threaded Type

Preferably designed for connections that need to be leak-proof and where servicing or washing is commonly done.

Flange Type

Marine or dry connection techniques for complex applications, typically of conventional type and semi-permanent.

Intubation Joint Type

This is a special type of connection utilized when it is required to control the flow of liquid in the system accurately.

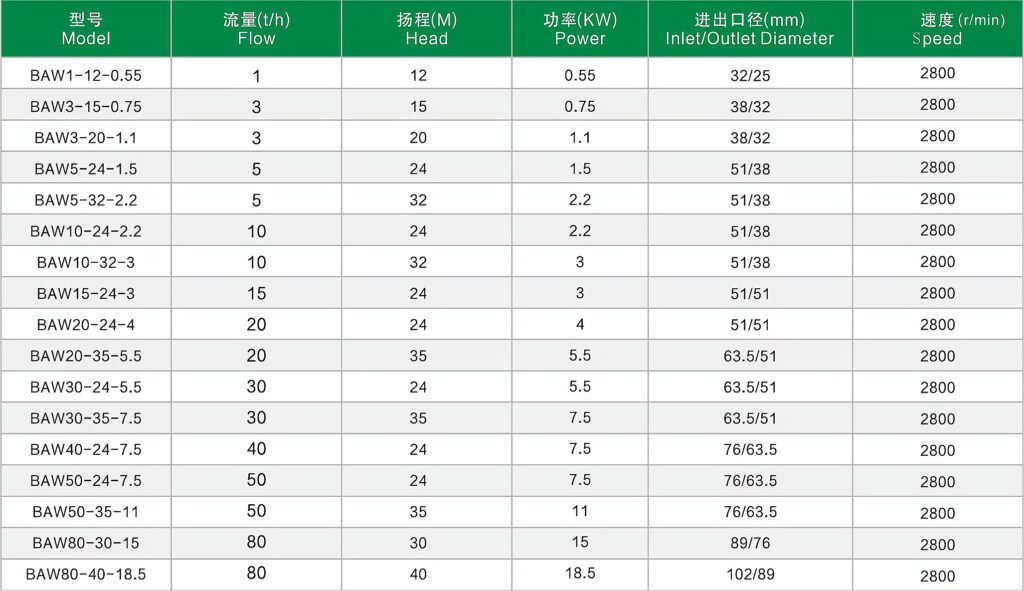

Main Parameters

High Efficiency

Pumping fluid at a high rate over long distances in an energy-efficient setup is what this pump achieves.

Environmental Sustainability

This pump uses minimal energy and resources, reducing environmental degradation.

No Dead Angles

Bumper rings are designed to eliminate the need for O-rings or seals, essential for maintaining cleanliness in industries requiring hygiene.

Wide Range of Usages

The pump can handle various liquids, from low-viscosity fluids like water and drinks to thick liquids like oils.

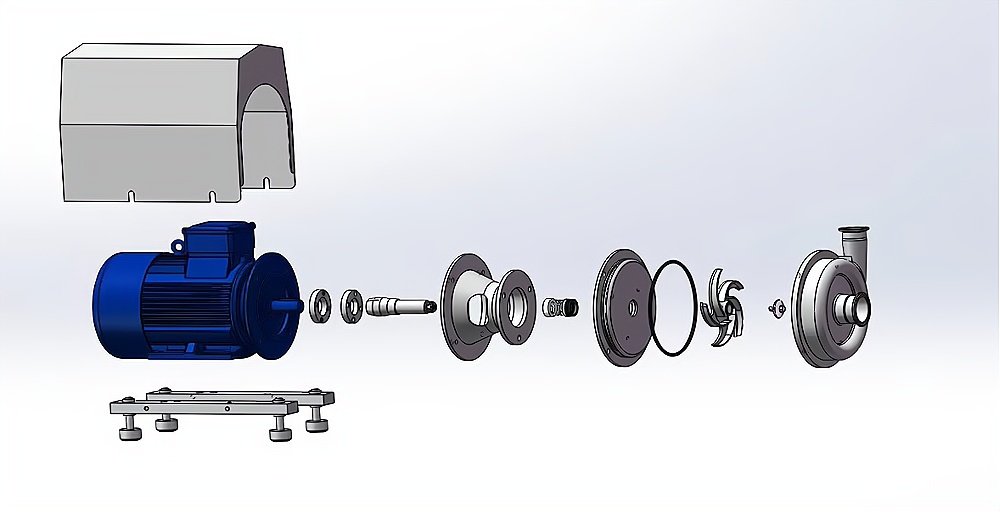

Pump with Additional Features

The pump can be customized with different inlet/outlet ports, motors, and protective accessories.

GMP Compliance

This pump meets GMP compliance, making it ideal for food, pharmaceutical, and beverage industries.

Applications

Due to its practicality and efficiency, this liquid transfer pump is applied in the following sectors:

Food and Beverage

Suitable for transferring juices, sauces, dairy products, and other fluids without contamination.

Oil and Dairy

Processes dairy and oil ingredients without compromising purity.

Daily Chemicals

Eliminates the risk of leaks and contamination during the transfer of liquid detergents and soaps.

Brewing

Efficient, safe, and hygienic movement of beverages like beer, wine, or spirits.

Environmental Protection and Water Treatment

High fluid flow makes this pump useful in environmental protection facilities, contaminated water treatment, and fluid recovery operations.

Frequently Asked Questions

What materials are used in the construction of a liquid transfer pump?

All parts that come into contact with liquids are made of SUS304 and SUS316L stainless steel, resistant to corrosion and widely used in liquid handling applications.

Can the pump handle higher viscosity fluids?

Yes, these pumps can operate with thick fluids such as potable water, oil, and dairy products.

Is the pump easy to clean?

Yes, the inner and outer parts are mirror-polished, preventing contamination and making it easy to clean.

What motor options are available?

The pump comes with a standard cast iron motor or an explosion-proof motor for safety in demanding environments.

Is GMP compliance necessary for these pumps?

Yes, the pump design complies with GMP regulations and is applicable in food, beverage, and pharmaceutical industries.

Can I choose the configuration of the inlet and outlet?

Yes, the pump offers various configurations, from fast spin collar types to threaded, flange, and intubation joint types, allowing customization based on your operation’s needs.

Conclusion

The selection of a liquid transfer pump will help avoid unwanted head flow problems, ensuring operational efficiency at an industry level. This well-designed pump complies with GMP regulations and offers customization features for various applications. Whether for food, pharmaceuticals, oil, gas, or environmental protection, this liquid transfer pump meets all your requirements. Contact us today to have your liquid transfer needs met!