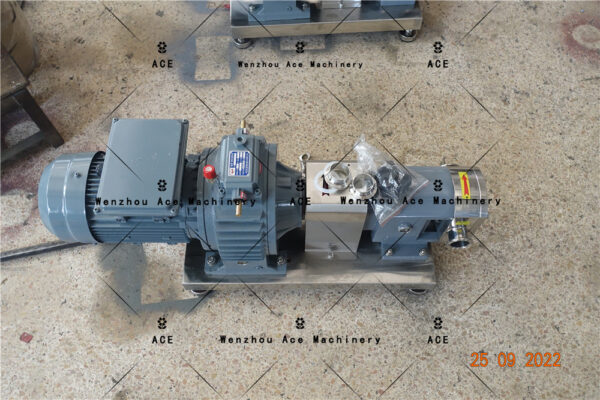

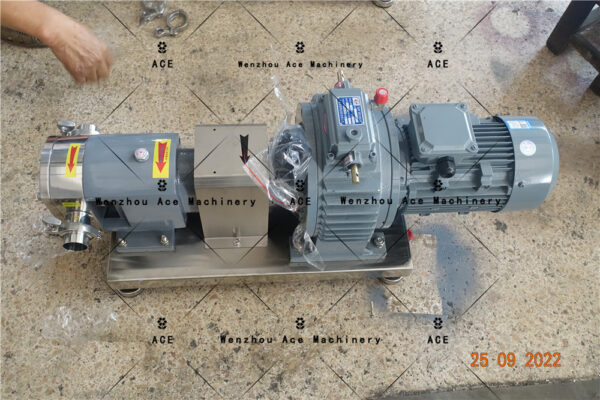

Key Specifications

- Material: 316L Stainless Steel

- Flow Rate: 0.5 to 60 L/min (depends on model and configuration, optional provision)

- Max Viscosity: 100,000 cP

- Max Pressure: 15 bar

- Temperature Range: -20°C to 150°C

- Connection Types: Tri-Clamp, DIN, or BSP (for customization)

- Seal Type: Mechanical or optipneut seal (optional)

- Motor Power: Range of 0.75 kW to 5.5 kW depending on the model

- Power Supply: 220V/380V, 50Hz/60Hz

Material: 316L Stainless Steel

The construction of the pump with 316L stainless steel is among the basic characteristics of this pump. 316L, being the best stainless steel for use in corrosive environments, is ideal for use in chemical, paste, and other industries that are gentle on the lower grade metals, which wear off easily. This material is designed particularly for industries that have stringent product and personal health standards, such as food and drinks, pharmaceuticals, and cosmetics industries.

Apart from resistance to corrosion, 316L provides extra strength for a long service life of the pump. The polished, smooth surfaces prevent the accumulation of matter and enhance the ease of cleaning and maintenance processes. This assures that even after prolonged use with difficult materials, the paste transfer pump remains at its peak working performance.

Features and Benefits

Handling of High Viscosity Liquids

Our paste transfer pump works excellently with highly viscous materials or paste consisting of creams, gels, and adhesives. The construction of the pump is durable, along with a powerful motor that rotates very thick materials into the container without the occurrence of pump unclogging or stalling.

Sanitary Design

Bearing in mind the food and pharmaceutical industries, the pump has a sanitary design that allows disassembly for cleaning purposes. The components made from 316L stainless steel satisfy high hygiene requirements suitable for applications that require stringent cleanliness.

Low Shear Pumping

The pump is made to move paste-type products gently to avoid exerting shear forces, which could ruin fragile components. This feature is important in industries like food processing and cosmetics, where the pumping process must not compromise product integrity.

Wide Temperature Range

The paste transfer pump is designed to operate in a broad temperature range from -20°C to 150°C, meaning it can function normally with both heated and chilled pastes. This versatility makes it useful in applications like pumping chocolate, creams, and adhesives in hot and cold conditions.

Customizable Options

Customers can customize several construction features, such as motor power, connection types, and sealing mechanisms. The range of purpose-built and standard model pumps will meet the needs of both high and low-pressure applications.

Energy Efficiency

Despite its high performance, the pump is designed to use minimal energy, reducing operational costs over time.

Easy Maintenance

Maintenance is straightforward and disassembly takes little time. The pump’s construction is simple, requiring minimal moving parts, which are the primary components prone to wear.

Common Issues and Solutions

Clogging with Highly Viscous Materials

A paste transfer pump can clog when handling thick pastes. Our pump solves this issue by including a strong motor and a broad pump throat to facilitate the smooth transfer of the thickest pastes.

Seal Wear Over Time

Seals may wear or break down during high-performance applications. To address this, we offer both mechanical and diaphragm seals, which are easy to service, ensuring the pump remains leak-free and operational.

Difficulty in Cleaning

Cleaning can be difficult, especially when dealing with sticky or highly viscous materials. However, our pump’s hygienic design and 316L stainless steel construction allow for fast, easy cleaning with minimal downtime, ensuring cleanliness and operational efficiency.

Overheating

Overheating may occur during prolonged use with hot pastes. Our paste transfer pump addresses this by offering additional cooling options for applications with high-temperature demands.

Conclusion: Invest in Reliable Paste Transfer

For a pump that excels in reliability, performance, and durability, our Paste Transfer Pump is the solution. This pump can handle even the most complex paste transfer operations, ensuring your processes run smoothly. With its 316L stainless steel construction, high flow rate, and customizable options, it’s an essential component of any production line.

Your products deserve the best, and the Paste Transfer Pump delivers. Contact us today to learn more and take your operations to the next level!