High-Quality Materials

Positive displacement pumps are made from high-quality materials that can withstand erosion, chemicals, and extreme temperatures and pressures. Depending on the specific requirements, the pump housing and rotor materials can be made from different types of materials. All of these points are explained in detail below.

316/304 Stainless Steel

Perfect for Food, Pharmaceutical and even Chemical Processing where hygiene and anti-corrosive properties are paramount.

ERW and other Castings of Iron

Provides high resistance to abrasion and ability to handle thick, viscous fluids in a natural state.

Ductile Iron

Able to withstand high pressure and flexible yet is wear and tear resistant.

Bronze

It is often applied for marine water and water treatment tactics. It has most anti-corrosion characteristics in seawater.

Seals and gaskets are manufactured using strong materials such as EPDM, Viton, and PTFE for extreme temperature, chemical, and abrasive resistance, and, as a result, your pump will be leak free and dependable.

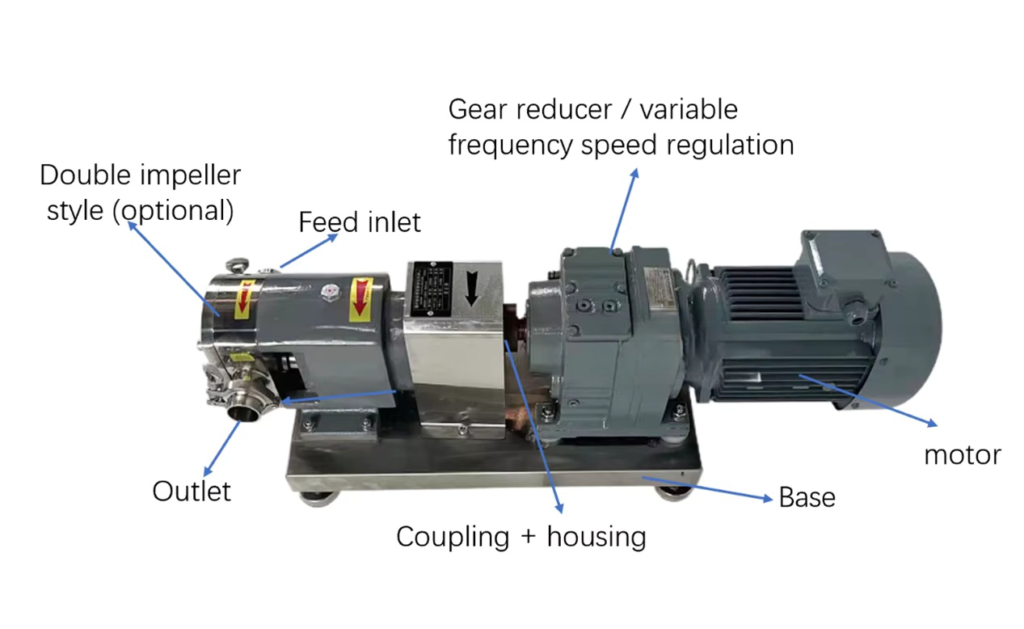

Positive displacement pumps key features

Despite being very easily achievable, the positive displacement pumps provide a number of benefits, making them worth putting to a number of applications. Below are some of the key features:

Constant Flow Rate

As far as the pressure in the system fluctuates, these pumps can maintain steady fluid flow rate with no fluctuation in the amount of fluid being transferred in the processes.

Handles Viscous Fluids

Positive displacement pumps are able to pump out thick oil as well as a syrup and many other fluids with very high viscosity. Thus, this type of pump is highly applicable in several fields.

Self-Priming

No more labor or effort as you don’t have to hand prime these pumps, they self-prime the system.

Customizable

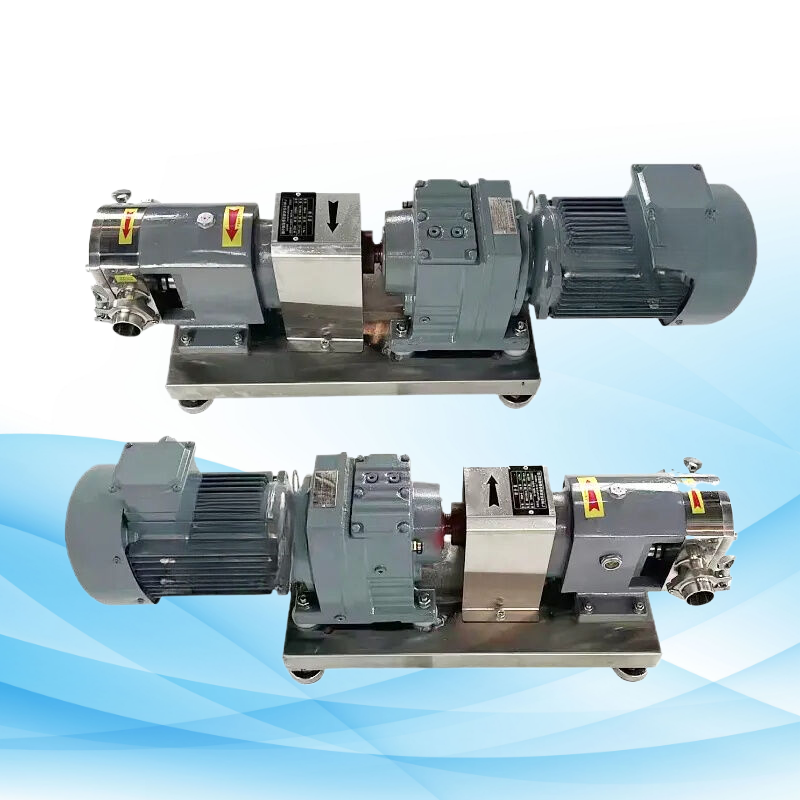

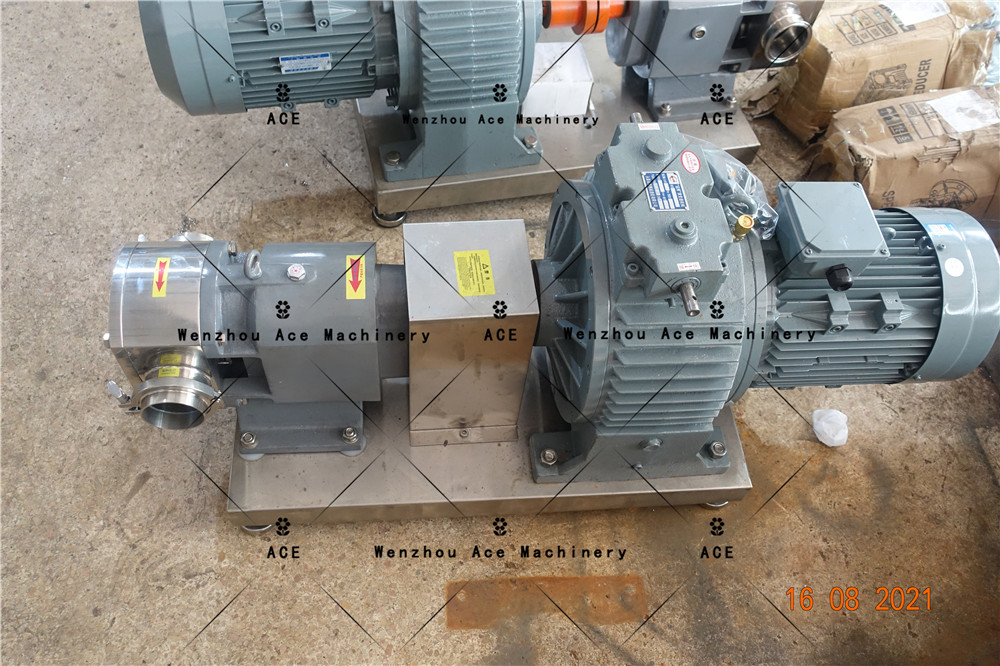

We have different components to meet your specification like the power of the motor from 1Hp up to 20Hp, explosion-proof motors, portable units with trolley, control panels, and frequency inverters to control the speed of the pump.

Efficient Power Usage

Providing appropriate functionality without excessive energy consumption, many of the diesel and electric pumps are exceptionally effective and efficient even when in continuous aid conditions.

Durable Construction

The construction of these types of pumps is aimed towards industrial purposes, meaning these pumps are able to handle severe conditions like high pressure, corrosive and abrasive conditions fluids.

Explosion-Proof Options

Available with explosion-proof motors for industries dealing with flammable or hazardous materials which are of paramount importance.

Specifications

Specifics of our positive displacement pumps are given subsequently for an understandable perspective:

Power Range

Motor ratings available from 1 HP to 20HP so that a range of operational requirements is met.

Flow Rate

Flow Type ranges from 5 GPM to over 500 GPM depending on the model, and horsepower.

Pressure Capacity

We currently have a range of power pumps that have a working pressure of 50PSI up to about, 1500PSI.

Temperature Tolerance

Fluids can be within a range of -40 Deg F and 350 Deg F depending on the pump design and material.

Viscosity Range

These pumps are specially designed to handle fluids of very high viscosity up to one million centipoises, for example oils, lumber syrup, molasses, and other viscous liquids.

Seal Options

Different mechanical seals such as ceramic, tungsten carbide and silicon carbide are offered depending upon the nature of fluids used.

Ports

Available ports of connection include NPT, flanged, tri-clamp and many others in order to avoid any difficulties in their installation.

Customization Options

We do appreciate that each application is unique and so are the needs. Therefore, we have put in place adequate measures that include various customization options to ensure the proper functioning of the pump meets your expectations.

Power Options

Offering flexibility in flow rate, pressure, and the functioning of the pumps, positive displacement pumps can be fitted with motors ranging from 1HP to 20HP.

Explosion-Proof Motors

For industries that work with flammable liquids or are in potential explosive atmospheres, explosion-proof motors are made available.

Portable Units

Our pumps can be wheeled or cart mounted and moved from area to area within your plants, making it easier to move to various locations.

Control Panels

Control Panels either manual or automatic can come with readout devices for the flow rate, pressure, temperature and other parameters.

Variable Frequency Drives (VFDs)

For effective pumping speed management, our models can accept VFDs, which provide cost-effective and smooth operation of the system.

Materials

Depending on the type of fluid that is to be handled, a variety of construction materials for the pump body, rotor, and seals may be supplied including stainless steel, cast iron, or bronze.

Applications

Owing to the strong design of positive displacement pumps, they are useful in a wide array of industries and applications. Here are some of its widely known applications:

Food and Beverage Industry

Suitable for moving highly viscous products like sauces, syrups, and pastes without shearing or damaging the delicate fluids and are also hygienically designed as per industry requirements.

Chemical Processing

The Ace pump provides versatile solutions to all types of industries in transferring all types of corrosive and abrasive materials, while also protecting the fluids from contamination due to damage to the pumps.

Pharmaceuticals

In the pharmaceutical industry, positive displacement pumps are an indispensable device for mixing and dosing the active ingredients due to the need of maintaining defined proportions and sterility.

Oil and Gas

Positive displacement pumps are particularly effective when moving thick mucilaginous fluids, places that are subjected to hydraulic forces and loads and require high degree pressures of crude oil, petroleum recognized as lubricants.

Water and Wastewater Treatment

These devices deal with sludge, slurry and other viscous materials in treatment plants which enhances the treatment of water and wastes.

Marine Industry

Marine bow bronze positive displacement pumps are employed to pump seawater, fuel, and other fluids necessary for vessel operations.

What Makes Our Positive Displacement Pumps Perfect for Your Needs?

When deciding which pump to purchase for your business, the overall quality, performance and robustness are the attributes to look for. Our positive displacement pumps offer:

Effective and Dependable Delivery

Whatever the type of fluid you are handling, whether thick, thin, volatile or viscus, our pumps ensure that there is a constant volume displacement, hence the processes remain uninterrupted.

Pumped-All-the-Ways-to-the-Max

Because of the wide variety of materials adopted, motor types used, features added including explosion-proof motors and VFDs, modifications of our pumps to suit your need is possible.

Proven Technologies

Our pumps have been designed and put to test in stringent conditions in various industries, including the pharmaceutical and food industries, giving you confidence in their use.

Round the Clock Support

We provide full technical help and consulting to select the optimal pump configuration for your needs and follow it with all necessary maintenance services to make sure that the pump works in optimal mode.

Buy Now

Do not skip the chance to enhance the characteristics of your fluid handling activities with our positive displacement pumps that are not only robust and efficient, but also customizable in almost every way. Ranging from 1 HP to 20 HP built-in electric engines, portable devices with advanced control systems and explosion-proof features are also on offer. Therefore, we will certainly meet the requirements of your industry. Our equipment guarantees excellent pump rates for even the most viscous chemicals, pharmaceuticals as well as thick food products. Call us now for more information on what we have and the customized quote that we can offer you!