Undeniably, a rotary gear pump is a quintessential tool, especially for efficient and effective best fluid transfer across multiple industries. These pumps are designed to work with a wide range of liquid products, such as oils, chemicals or even thick fluids. Operating in the fields of manufacturing, agriculture, pharmaceuticals or even the petrochemicals’ industry, a rotary gear pump operates as your ideal fluid moving device.

Key Features of Rotary Gear Pumps

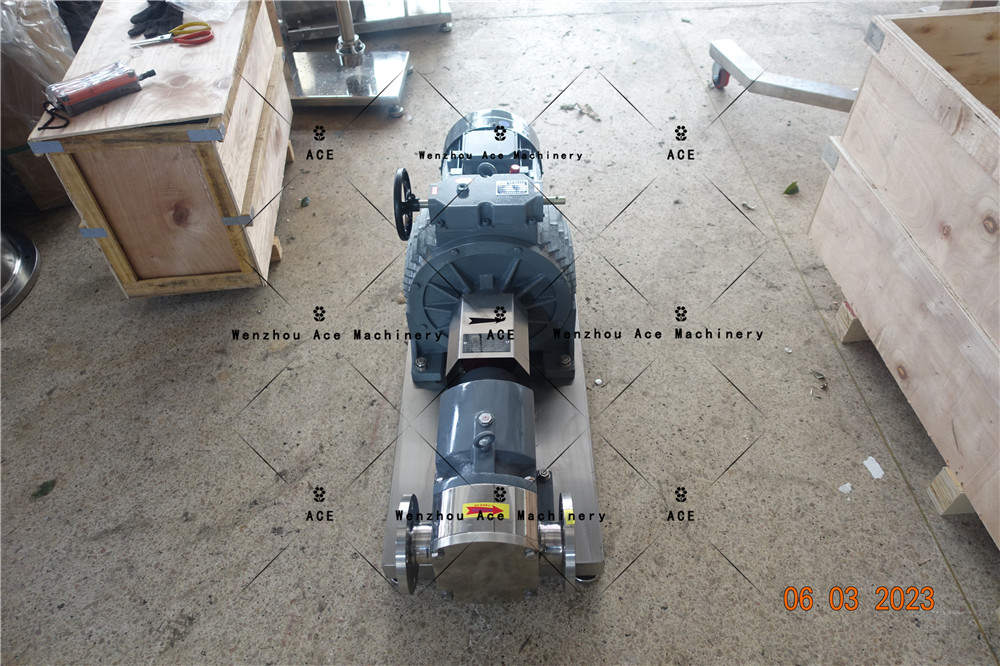

Exceptional Construction

Rotary gear pumps are manufactured only with premium quality metals and parts. Choices include 316L stainless steel for enhanced resistance to corrosion, which is ideal for hospital applications and 304 stainless steel, which is ideal for more generic, hospital wide use. These choices will extend the wear and tear life, as well as maintenance requirements, for those units in the best applications.

Comprehensive Order Size

The order sizes stand from 1.5KW to 55KW, thereby allowing rotary gear pumps to best fit across a spectrum of operations from domestic use to heavy-duty industrial tasks.

Wide Range of Voltage Applications

From 110V to 600V, these pumps are able to best suit different power supply mechanisms, from domestic units to large-scale industrial units.

Strong Efficiency And Precision

With internal features that minimize internal leakage, these pumps ensure the accuracy and precision of flow rates, which enables operators to exercise fine control over the fluid. This makes the pumps useful in precise metering and dosing.

Strong Design Yet Compact Built

As the footprint of rotary gear pumps is small, they can be installed in areas that are space constrained. Further, as they have a robust construction, less maintenance is required and thus less downtime is incurred.

Applications and Usage Scenarios

There is hardly an industry that does not benefit from a rotary gear pump, as it has multi-industry support:

Petrochemical Industry

Effectively transport and meter lubricants, fuel oils, and other petrochemical products.

Food and Beverage Industry

Reasonably use viscous liquids which include syrups, oils and molasses while meeting hygiene requirements.

Pharmaceuticals

Ensure accurate dispensing of medicinal liquids and other viscous substances.

Chemical Processing

Move around acids, alkalis and many other substances safely and efficiently.

Agriculture

Use it for irrigation and applying liquid fertilizers and relying on consistent flow rates to get the job done.

For instance, imagine employing a rotary gear pump to facilitate the lubricant delivery system in your factory. The rotary gear pump allows for ease of use while ensuring an output that is consistent and inclusive of well-used power which leads to minimization of waste and in turn competitive advantage.

Key Technical Specifications

- Flow Rate: Adjustable according to the application.

- Material Options: 316L stainless steel for greater corrosion resistance, and 304 stainless steel for general applications.

- Voltage Options: 110V, 220V, 380V, 415V, 480V or even up to 600V.

- Power Range: 1.5KW up to 55KW.

- Temperature Range: Designed to be used with fluids in an ambient to extreme temperature range.

Why Choose Our Rotary Gear Pumps?

Efficiency

The suggested designs enhance the performance in terms of energy usage.

Customization

Configure the pump’s power, voltage and materials to match your requirements best.

Expert Support

Get support in the selection and management of your pump from a professional expert.

Common Questions About Rotary Gear Pumps

Q1: Will rotary gear pumps move abrasive liquids?

A: There is a rotary gear pump for abrasive liquids, however it is not an ideal technology for them. It is always better to seek out our experts for more specific design configurations.

Q2: What maintenance do these pumps need?

A: The maintenance is very less and consists primarily of inspecting all the seals and gears to check if they are functioning properly.

Q3: Will this pump be able to work with high viscosity fluids?

A: Certainly, rotary gear pumps work perfectly fine with high viscosity fluids like oil, syrup, and even grease.

Q4: Do you provide any warranty?

A: Absolutely, buying our gear pumps comes with an inbuilt warranty for your peace of mind.

Enhance Your Procedures Right Now

Customize rotary gear pumps for your business and take your fluid transfer systems to the next level of efficiency, reliability, and precision. Perfect for various industries, these pumps can be easily tailored to your requirements. Make an order today to bring unyielding efficiency to your operations.