Understanding Chemical Transfer Pumps in Agriculture

If you want to move chemicals which are toxic or essential for your crop production in agriculture, you will use chemical transfer pumps. They are very useful as they deliver fertilizers, pesticides, and other chemicals at desired points without any wastage.

Components of Chemical Transfer Pump

There are a number of considerations when it comes to choosing a chemical transfer pump. The type of chemical is also not enough; the viscosity and temperature of that chemical play an important role in the selection of the right type of pump. In addition to that, you have to analyze the flow rate and pressure of the pump to comprehend if they will meet your needs. Selection of the right pump will minimize the loss of time and enhance safety measures in the process of agriculture operations.

Knowledge About Chemical Transfer Pumps

It is understanding the different transfer pumps of chemicals available for agriculture and how to use each that will inform the choice of the best pump. This will support farmers in making the right choices for the correct purpose.

Categories of Chemical Transfer Pumps

Centrifugal Pumps

Centrifugal pumps are characterized by centrifugal action. They are outfitted with an impeller that rotates to carry fluids with certain chemicals. They perform best on the movement of fluids that have low viscosity and are well suited for moving big quantities at a steady rate over long periods. Furthermore, they are easy to use, and hence the parts are also easy to troubleshoot.

Diaphragm Pumps

Diaphragm pumps utilize a replaceable elastic diaphragm to render pumping action. They are capable of handling diverse chemicals, including corrosive and thickened ones. These pumps are very chemically resistant and provide accurate metering.

Peristaltic Pumps

Peristaltic pumps are such that a tube enclosing the fluid is squeezed in order to move fluids. They are ideal for evacuation of fluids that are sensitive, requiring minimal forced methods. You are also able to take advantage of the seal-less design, which has a lower risk of leakage. These pumps are hygienic and low maintenance.

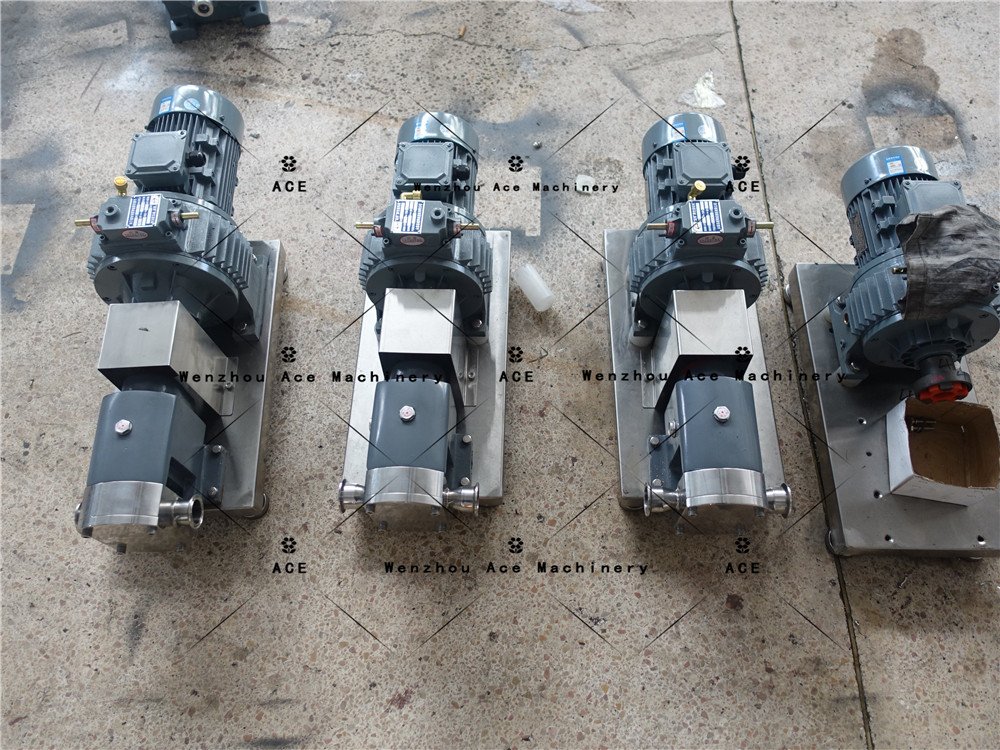

Gear Pumps

Gear pumps transfer fluids by the turning, intermeshing gears. These pumps are suitable for viscous fluids, and rhythmical flow is ensured. They are reliable in controlled pressure applications, and their sturdiness makes them dependable in service.

How Chemical Transfer Pumps Work

Schematic Operating Principles

Chemical transfer pumps involve the application of pressure difference to lift as well as transfer fluids. When shopping for a pump, one must consider the chemical’s properties to be encountered within the pump. Mastering these concepts makes you capable of understanding which pump is suitable for agricultural operations, such as pumping livestock waste.

Key Components and Their Functions

In every chemical transfer pump, several parts such as the motor, impeller, or diaphragm are incorporated. These parts are complemented by extra components in order to function properly. Knowing their functions makes it possible to operate and explore maintenance practices for the pump.

Selection Criteria for Chemical Transfer Pumps

Chemical Compatibility

Material Considerations

Different materials are used for constructing the pump, which will be in contact with different reagents. Select pumps with abrasion-resistant materials to prevent wear.

Corrosion Resistance

Corrosion is a major threat that may compromise the integrity of the pump and cause leaks. Pumps should be selected that can withstand corrosion, especially in the presence of highly reactive chemicals. For such requirements, materials like stainless steel or certain plastics are commonly used.

Flow Rate and Pressure Requirements

Calculating Flow Rate

Identify the flow rate necessary for the successful running of your operation. Determine the volume of fluid that needs to be moved within a given period to ensure you select a pump that will meet your requirements.

Determining Pressure Needs

The pressure needs of the system depend on the distance from the discharge point to the point of application and the elevation the fluid must reach. Ensure the pump can handle these pressure levels efficiently.

Environmental and Safety Considerations

Spill Prevention

Spills can damage ecosystems and lead to unnecessary costs. Choose pumps that are leak-proof to prevent fluid spills. Some systems, such as non-centrifugal pumps, offer better leak prevention.

Safety Protection

Safety should always come first. Select pumps with features that prevent user safety from being compromised, such as cut-off valves or alarms. These enhance a safe working environment when dealing with chemicals.

Operational Areas of Transfer Pumps

Installation and Setup

Site Preparation

It is important to plan the site for a chemical transfer pump properly before the pump is installed. The site should be clean, and the pump installed on a solid, even base to prevent vibrations. Temperature and humidity at the site may also impact the pump’s performance.

Installation Guidelines

Follow the operation manual of the manufacturer closely. Minimize suction lift and ensure all connections are securely fastened to avoid leaks. After installation, check if the pump is performing as expected to avoid common installation mistakes.

Maintenance and Troubleshooting

Aspects of a Proper Maintenance Program

Proper maintenance ensures that the chemical transfer pump works as intended. Filters and strainers should be cleaned to prevent blockages, and moving parts should be greased regularly. Leaks should be addressed promptly by tightening or replacing seals as necessary.

Problems and Solutions

Leaks are a common issue caused by worn-out seals or loose connections. If the pump fails to build pressure, check for clogs in the impeller or tubing. Regular checks and repairs help maintain pump efficiency and prevent mechanical failures.

Conclusion

Finding the right chemical transfer pump for agriculture involves balancing important factors such as chemical tolerance, flow rate, and safety. Whether you need a centrifugal, diaphragm, peristaltic, or gear pump, the right design and planned maintenance will ensure efficient and safe agricultural operations. Always remember, the right pump not only satisfies operational requirements but also safeguards the environment and your budget.