Material and Construction

The construction of the chemical transfer pumps determines largely the safety of the user, because some substances handled can be very corrosive. Generally, these pumps are produced with advanced and chemically resistant materials such as:

Polypropylene (PP)

Besides being a thermoplastic polymer, this material has wide applications in the ultramodern world due to its resistance to chemical and corrosion, and it is lightweight. Polypropylene has also been found to be useful in submersing and flow of chemicals such as acids, alkalis and solvent liquids.

Polytetrafluoroethylene (PTFE)

To most as Teflon, polytetrafluoroethylene is widely recognized for its high range of chemical and extreme-temperature use and hence can be put in extreme conditions. It is frequently utilized in the linings and gaskets of the killer pump to protect them from destruction.

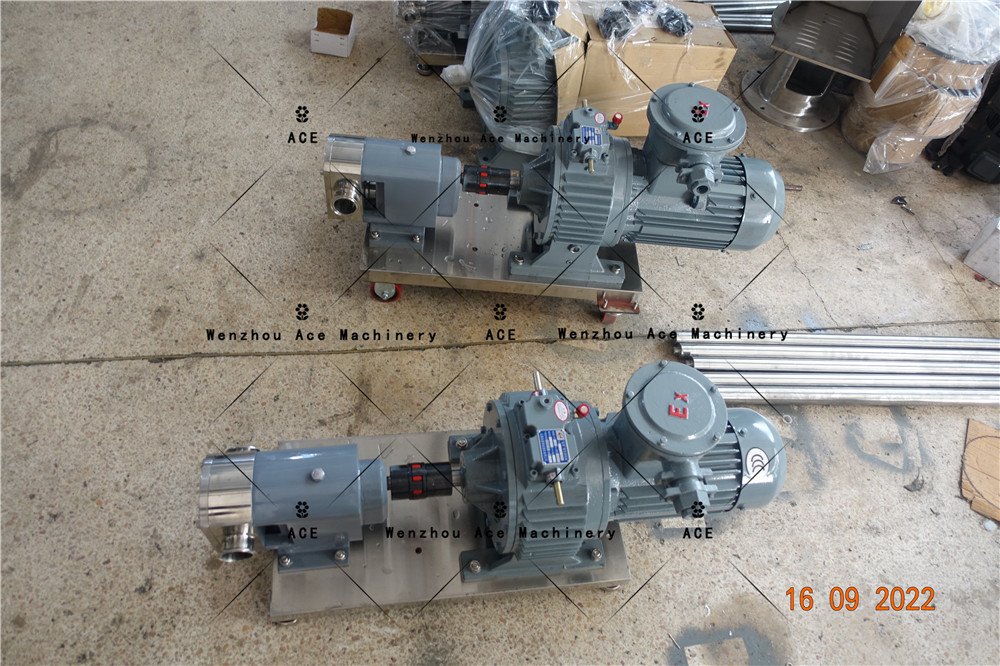

Stainless Steel

Where chemicals are slightly more aggressive or less aggressive, but there is need for mechanical strength in the application, stainless steel pumps are generally used. Because of the resistance of the metal to oxidation, it suits chemical environments.

Viton and EPDM Seals

These elastomers are extensively used in the seals of the chemical transfer pump, used to withstand a variety of working conditions.

Key Features

To meet the very requirements of aggressive working conditions, chemical transfer pumps are provided with a number of important features:

Corrosion-Resistant Materials

Chemically resistant materials offer protection to the pump and enhances its functionality and lifespan even in the most corrosive of environments.

Leak Proofing

The risk of evaporation of active substances is reduced to a minimum by using high quality seals and gaskets such as ecologically safe PTFE or Viton materials.

Self Priming

It is possible to make some chemical transfer pumps self-priming. This means that they can suck in the liquid into the pump without any manual assistance in priming. This improves ease of operation and increases efficiency.

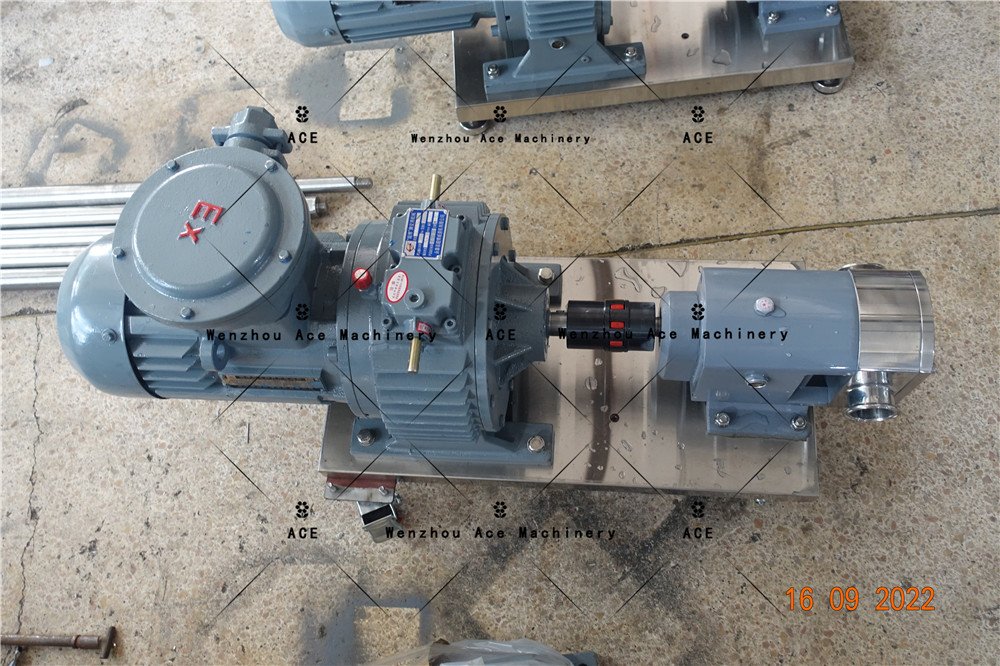

Explosion Proof’s

For applications with flammable chemicals, explosion proof model pump designs are available for use. Such models prevent any spark, flame or potential ignition sources from coming in contact with flammable chemical substances.

Varied Flow Rates

A chemical transfer pump can accommodate more than one flow rate and hence can be used in a low volume laboratory or large volume factory processes.

Applications

The chemical transfer pump has found use in several industries because of the wide variety of fluids it can safely transfer. Some of the common applications are:

Chemical Manufacturing

Acids, solvents, and alkalis are transferred during manufacturing activities.

Water Treatment

Injection of compounds like chlorine, sodium hypochlorite, or sulfuric acid into water systems.

Pharmaceuticals

Distribution of sterile and high-purity chemicals in relation to the products.

Mining and Construction

Rough handling of chemicals during mineral processing and wastewater treatment.

Agriculture

Movement of fertilizers/pesticides and other agrochemicals.

Common Issues

Even though the chemical transfer pumps are in most cases efficient, there are a couple of problems that most users should be aware of to achieve perfect functioning.

Seal Wear

A chemical transfer pump has seals that may eventually break down due to erosion from aggressive chemicals after a certain period of time. These seals have provisions that make repairable maintenance possible.

Clogging

Most situations of clogging arise from some of the chemical solutions that tend to be viscous or those that have particulates in them. In this case filters have to be placed and constant flushing of the pump has to be done.

Cavitation

Cavitation takes place when voids appear in the pump due to the presence of air. This decreases the pumping efficiency as well as risks damaging the pump. Oiling or keeping up the required flow may reduce this problem.

Chemical Compatibility

It is very critical to check the compatibility of the pump parts exposed to the wild transported chemicals. If incompatible materials are utilized, then undue wearing or breakdown may easily occur.

Temperature Limitations

Some pumps can withstand excessively high temperatures, but for the sake of safety ensure that chemical transfer pump components such as the motor are operated within the temperatures suggested.

What is the need to use our Chemical Transfer Pumps?

If you want a chemical transfer pump that provides the highest level of safety, our chemical transfer pumps are the best pick. The use of high performance materials such as PTFE and stainless steel makes the units highly resistant to corrosion and thermal damage. Our pumps are durable and offer reliability for a chemical, pharmaceutical and even water treatment facilities. Some are self-priming even while others are leakproof resulting to trouble free and dependable use with low maintenance requirements.

Why settle for less when you can do better?

Contact us today and learn which of the many chemical transfer pumps on offer is the most suited to you.