Without a doubt, a chocolate delivery mass pump is not something to worry about, as it is an important tool in chocolate mass production. This one-off piece of equipment is specifically designed to allow the movement of chocolate mass liquids throughout the various stages of the chocolate production process without affecting its quality or changing its ability to be processed further.

Chocolate production specialists clearly need to know how this pump works as it has a role in determining the quality of the end product, the efficacy of the process, and the ease of scaling up the operations. The users’ knowledge and understanding of the essential elements of equipment such as a pump contribute a lot to the effective operation of the equipment being employed in production. Next, we will elaborate on the purpose, working principle, construction, advantages, and practical uses of the pump so that one gets the picture of the pump properly.

Significance Of A Chocolate Delivery Mass Pump During The Annual Chocolate Production

In the process of making Betters, which are thick and viscous like cake material, such as chocolate butter, melting chocolate, and chocolate mass, it is recommended. Chocolates or china mass oil materials of such variations are thicker and more viscous than water and hence have to be served through volumetric means.

Purposes of Mass Pumps for Chocolate Delivery

- Uninterrupted Transfer: Chocolate delivery mass pumps allow the mass manufacturing of the chocolate to be relocated between multiple stages of the production process.

- Temperature Control: The right temperature is maintained to ensure that the chocolate does not become spoiled or solidify.

- Hygienic Policy: Industry-grade materials serve the purpose of industrial protection and keep the issue of hygiene in consideration.

- Volume of Manual Labor: With lesser manual actions required, quicker manufacturing is guaranteed with a decrease in chances of human error.

How Does a Chocolate Delivery Mass Pump Operate?

In a chocolate delivery mass pump, the multifunctional chocolate devices have special design elements incorporated to help meet the demanding pumping requirements. Below is a simple explanation of how this device operates, with the aid of the walkthrough.

Primary Functionalities

- Feeding Mechanism: The pump is fed with a well-prepared chocolate mass, which can either be done manually or via automatic settings.

- Heating System: Components that are integrated limit the hardening of chocolate by assisting the chocolate to remain soft.

- Pumping Action: Movement through the pipe structure is achieved from a rotary or piston-type mass expelling mechanism.

- Output Limitations: The standards defined for the flow rate and pressure can be adjusted to a certain extent depending upon the type of item being manufactured and its needs.

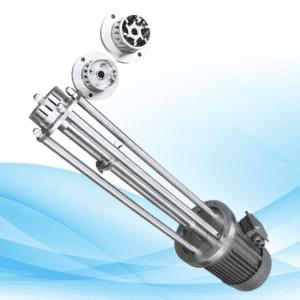

Features of the Chocolate Delivery Mass Pump

- Material of Construction: To maintain hygiene, all equipment is constructed in stainless steel or food-grade materials.

- Temperature Control: It has a heating additive to maintain the chocolate in its liquid form.

- Adjustable Chocolate Mass Delivery: The equipment makes it possible to change the rates and amount of mass delivery to the pumps of various levels.

- Cost Reduction: Different designs save energy, thus reducing costs involved during the process.

- Protection of the Equipment: The materials employed facilitate ease and speed whilst cleaning and maintaining the parts.

Integrating a Chocolate Delivery Mass Pump: The Advantages

Adding a chocolate delivery mass pump to the production line has the following benefits:

- Ensures quality consistency and steady supply

- Increases production efficiency and scalability

- Complies with hygiene standards

- Reduces overhead costs through energy-saving mechanisms

- Minimizes material wastage

A Massive Range of Chocolate Delivery Mass Pump Uses

Chocolate delivery mass pumps are useful in different stages of chocolate preparation that may include:

- Tempering and pouring into molds

- Accurate pouring into the molds

- Coating and spraying applications

Best Maintenance Tips for Chocolate Delivery Mass Pumps

There are certain best practices for the regular upkeep of equipment to maximize its operations and increase its operational life:

- Cleaning such as steam injection cleaning on a routine basis

- Checking of pipes at regular intervals to ensure that they do not get blocked

- Checking of the temperature control systems to ensure they are functioning properly

- Application of lubrication grease that is safe for food

Frequently Asked Questions

What is a chocolate delivery mass pump?

In the simplest terms, such a pump is a hefty device that is utilized in the chocolate industry to facilitate the transportation of liquid chocolate efficiently while ensuring cleanliness and temperature control.

How is a chocolate pump kept at the ideal temperature, and why is it widely needed?

It is crucial to have a pump for the chocolate to prevent it from hardening or losing its quality, and the pump helps maintain consistent quality.

How do I select the right chocolate delivery mass pump for use?

You will consider the energy used, ease of maintenance, and the amount of chocolate needing to be pumped.

What are some other hygiene-approved thick food substances besides fillings that the pump can be used for?

It can be used for syrups and creams.