How Gear Honey Pumps Work

The efficiency of gear honey pumps is dependent on a pair of gears that both rotate and capture honey between them so they move it through the pump. Gears that are engineered like this are classified as spur or helical because both have to move in order for the honey to pass through. The flow of liquid within the pump is much more consistent due to the arrangement of solenoid valves around the liquid discharge port. The watery content of the honey also gets measured by the rotational speed of the pump gears, but it will be dampened a sheer amount due to the close-tolerance fitting of the pump.

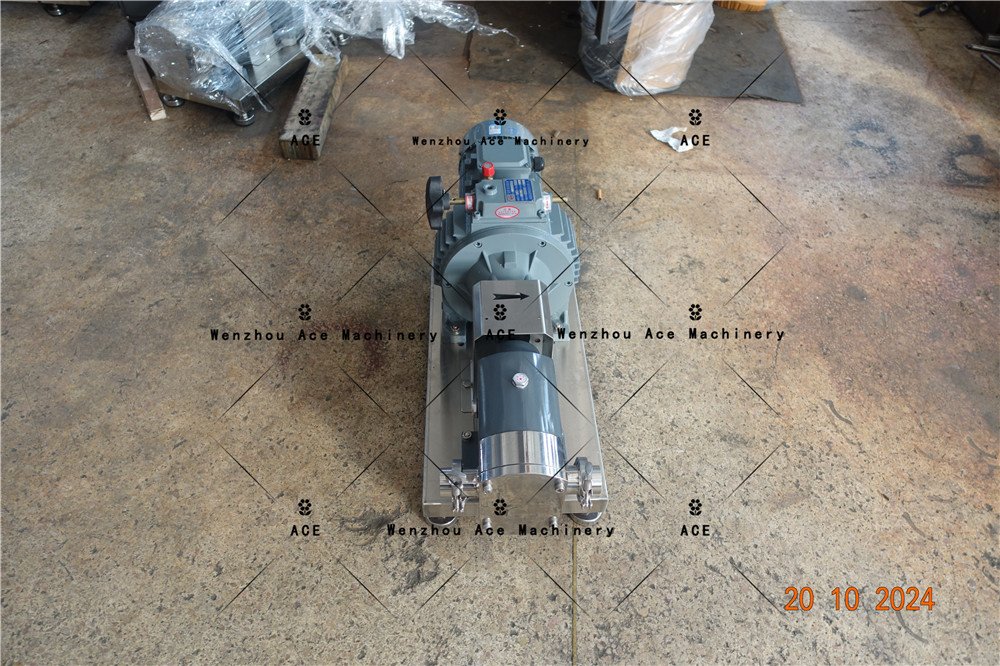

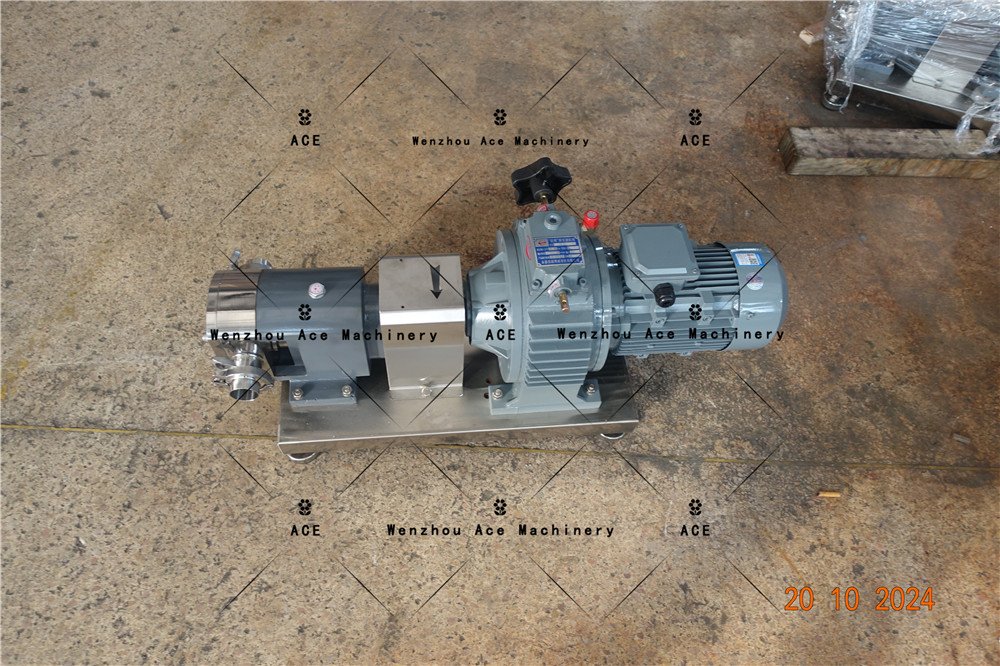

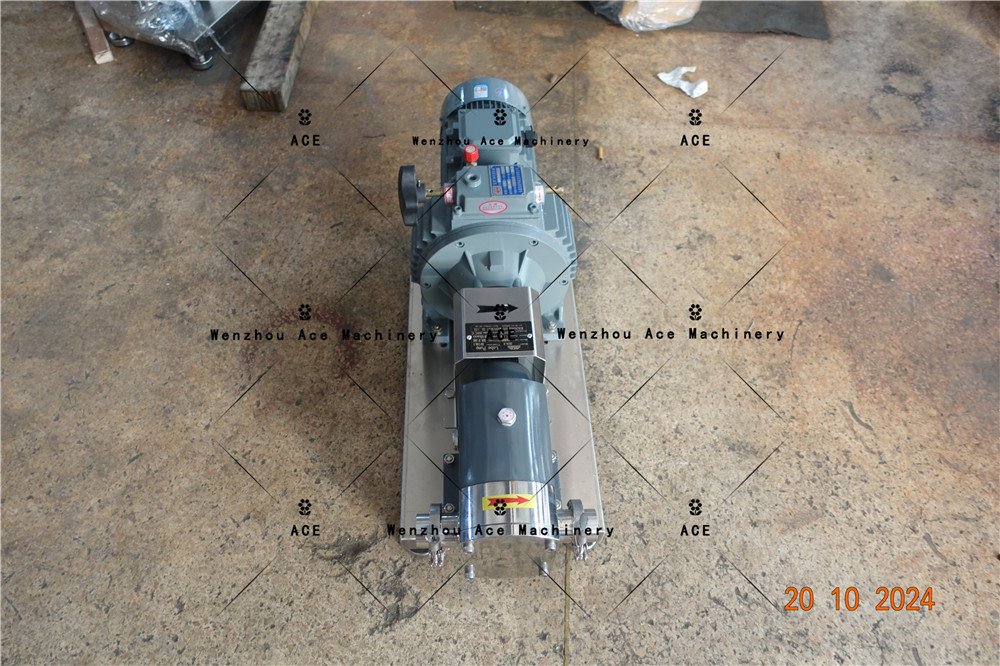

Main Parts of Gear Honey Pumps

- Gear chamber

- Inlet and outlet valves

- Sealing mechanisms

- Heating jackets (for temperature control)

Applications of Gear Honey Pumps

Gears honey pumps are used in different industrial environments where there is the need to count on handling of viscous liquids. Due to their characteristics of having to sustain thick and thin substances, their area of application is vast in nature:

Food Processing

Especially in honey production, these pumps have been used to convey raw honey into the processing tanks and this does not compromise the quality of the product.

Cosmetics and Pharmaceuticals

Apart from honey, these pumps are very useful in lifting other viscous materials such as lotions, creams, and syrups.

Agriculture

Such pumps are employed by honey producers, beekeepers, and even others for bottling and also for storage.

Advantages of Gear Honey Pumps

Gear honey pumps have many advantages which make them suitable for industries which deal with honey and other viscous materials:

- High Efficiency: Because of their gear mechanism, honey is able to have non-pulsating flow which increases its efficiency.

- Durability: Such pumps have been proven that they can last long because of their structural designs.

- Precise Control: Due to the control of flow rate, it includes the ability to be bottled or packaged, making it an attractive operation.

- Low Maintenance: After considering the initial setup, gear honey pumps are easy to maintain and operate compared to others which suffer greatly from clogging issues.

Key Features to Consider

When choosing a gear honey pump, it is necessary to consider a number of features so that efficiency is achieved:

- Material: Food-grade stainless steel is often the best choice, since it has a longer lifespan and is compatible with edible substances.

- Capacity: Due to the nature of the operations, some of the operations will need pumps with higher throughput.

- Flow Rate and Pressure: The right combination will vary with the viscosity of the honey and the desired production rate.

- Temperature Control: For honey, having the pump’s heating systems accurately controlled eliminates the problems of crystallization and clogging.

Types of Gear Honey Pumps

There are a few different types of gear honey pumps available, each suited to specific needs:

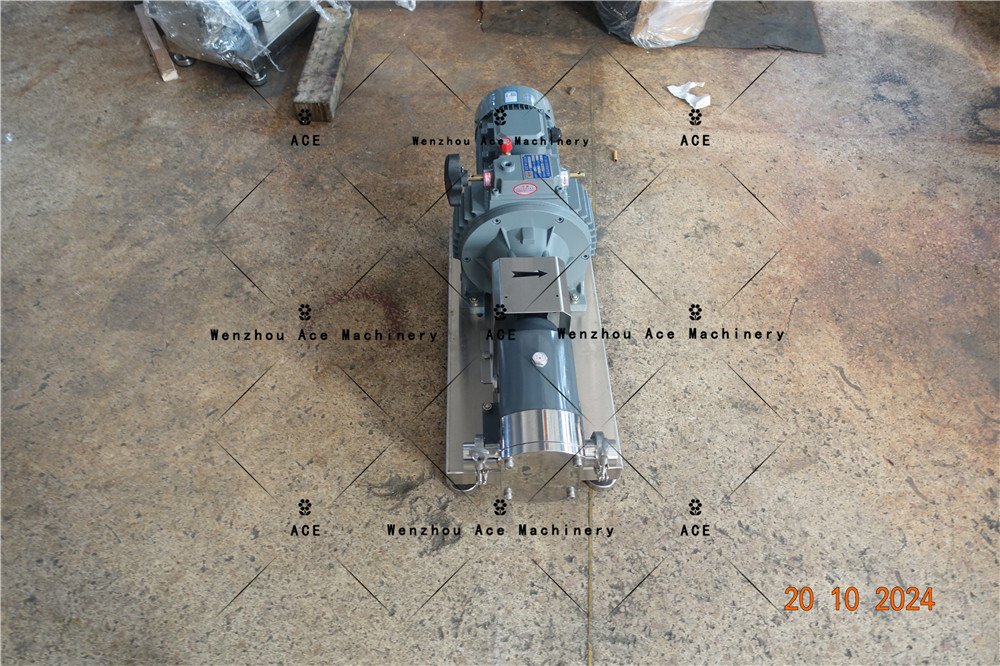

Rotary Gear Pumps

Pumps which transfer honey through internal gears that mechanically spin in a circular motion.

External Gear Pumps

Honey moves continuously about the pump by being pinched within the interlocked teeth of the two gears.

Internal Gear Pumps

One gear spins around inside an outer one causing honey to be sucked through a closed structure.

How to Choose the Right Gear Honey Pump

In choosing the correct gear honey pump, the type of honey and its viscosity plays a key role, as well as the repeating requirements of the firm. Just a few other points to note include:

- Flow rate: Ensure the pump can handle your desired output.

- Compressed air: The use of compressed air facilitates the running of the pump but can be considerably costly and one may also need to rotate or switch between different air sources.

- Food Safety: Any gears involved in the task of pumping may lead to the displacement of food particles and must be able to meet any food safety regulation standards such as CE or FDA.

Maintenance and Care of Gear Honey Pumps

Performance and durability over extended periods are essential aspects that require routine upkeep. Gears within a pump require maintenance and not only pump seals, which should firstly be performed as a progressive inspection routine:

Cleaning

Respond to alarm notifications by removing countdown periods for cleaning, otherwise simply wait until the end of work shifts where the pump can easily be disassembled.

Lubrication

Gear components which are encased within an ox-bioplastics shell that has a smooth surface must be capable of lubrication for the purpose of reducing friction between gear surfaces.

Every part of the pump including veins and covers should always be inspected with each installed device. Any abnormalities in either one of these areas should be thoroughly analyzed and corrected or replaced if possible.

Innovations in Gear Honey Pump Technology

The combination of high-quality consistent energy-efficient designs of new gear pumps, including but not limited to smart pumps, looks to remove or minimize flow rate dependencies by managing thermometer-centered on smart devices including tablets. More modes of operations assist in the better utilization of modern gear honey pumps, increasing their efficiency as well as cutting down operational costs, possibly creating an economically viable ability to replenish through.

Safety Considerations

To avoid long-term damages and uphold safety while performing a honey pump task, remember to always handle the oppressed liquids at room temperatures. It is advisable to rotate the honey pump cylinders in order to engage honey easily and other honey liquids to be effectively handled at the relative average temperatures.