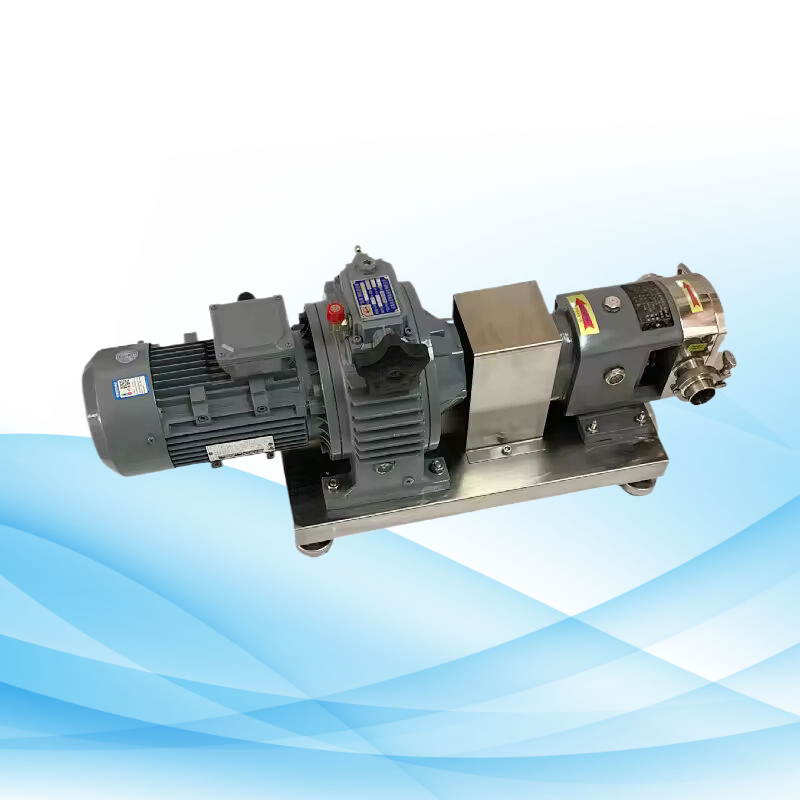

Corrosion Resistance Feature by Premium 316L Stainless Steel

The 316L stainless steel used in a construction of this pump is perhaps the most important feature for a material with a strong corrosion resistance, especially when used for pumps submerged in chemicals such as the contents of shampoos. 316L grade is resistant to rust, wears and degradation and is thus best employed in manufacturing of cosmetic and personal care products. Unlike plastics or composite materials such as resinous liners that are deteriorated by chemicals like acidic or alkaline substances over the years, 316L maintains its physical and chemical properties and thus every pump remains safe, operational and hygienic for the whole duration of its use.

Part of the hygienic approach is the addition of smooth inner surfaces that do not allow the retention of product residue and facilitate easy cleaning rotary. This is also helpful specifically in reducing the chances of contaminants getting into the shampoo at any stage.

Lobe Pump Technology for Gentle Product Handling

The lobe designs used in the shampoo transfer pump, make it possible to transfer the viscous and thick products, like shampoos, effectively. Lobe pumps operate by using their rotors to generate enclosed spaces which pull and then gently expel the product. This gentle action is essential in preserving the viscosity and texture of shampoo, avoiding incorporation of unnecessary air in the product and reducing shear stress that may change the consistency of the product.

In addition, there are no contacts between lobes; they are self-induced therefore the pump parts do not get damaged and this increases the time within which the pump will function. It easily adapts to lotions gels and creams in addition to shampoo and is therefore economical to the beauty products manufacturing process because of its wide range of usage.

High Performance and Efficiency

This Shampoo Transfer Pump is made with great performance.

It operates with very low pulse levels; consequently, the shampoo is transferred evenly without bubbles being formed. The

which contains a lobe pump circulates at a specific flow rate which lowers sponge wastage, Spearing every portion of shampoo.

Besides, the device is able to adjust to varying flow rates and pressures so that it is suitable for different production needs, whether there is a need for fast moving bulk transfer or slow and accurate dispensing. Due to the sturdy structure, the load of the operational cycle does not affect the pump, and thus the risk of breakdowns and production halts is low.

Easy Maintenance and Cleaning

The Pump also features a quick disassembly feature that enhances the ease of the maintenance activities. The design enables effective and quick cleaning between product batches, a very important feature of any cosmetic production line, fat should be avoided. Moreover, since lobe pumps usually have less component in terms of gyroscopic construction, there is little wear and tear requiring maintenance to be less frequent and simple.

This easy maintenance does not only trim down operational hours but also trims down operational expenses which means in the long run the Shampoo Transfer Pump is an economic viable machine to the business.

Applications and Versatility

When the pump has been made to perform the function of the transfer of a shampoo only in mind, its strong and adaptable features are sufficient to facilitate many other cosmetic and personal care products like conditioners, lotions, body washes, creams, and gels as well. Its versatility allows it to handle liquid products of varying viscosities, whether it is used for suctioning out raw materials or during the filling process of packaged goods.

This rotary pump comprising 316L stainless steel with moderate speed can work on delicate and thick products alike without making changes to their own properties. Whether you are a small business looking for a reliable solution for a short production run or a major manufacture requiring something tough – this model is just what you are looking for.

One strategic problem that competitively strategic moves must address is the availability of comparable products and practices in the industry. Outsourced shampoo transfer systems with effective shielding from contamination have also developed. The Shampoo Transfer Pump is one such reliable, cost-effective and multifunctional device which is meant to transfer viscous materials of the like shampoo and is free from all violations of the required level of sanitation.

Yet, you do not have to make any concessions in terms of how you go about your production. Instead, get a Shampoo Transfer Pump today and appreciate the advantages of the lobe pump technology and corrosion-resistant 316L.

Reach out to us now to find out how this pump can revolutionize your production practice and help you consistently create products of the highest quality.