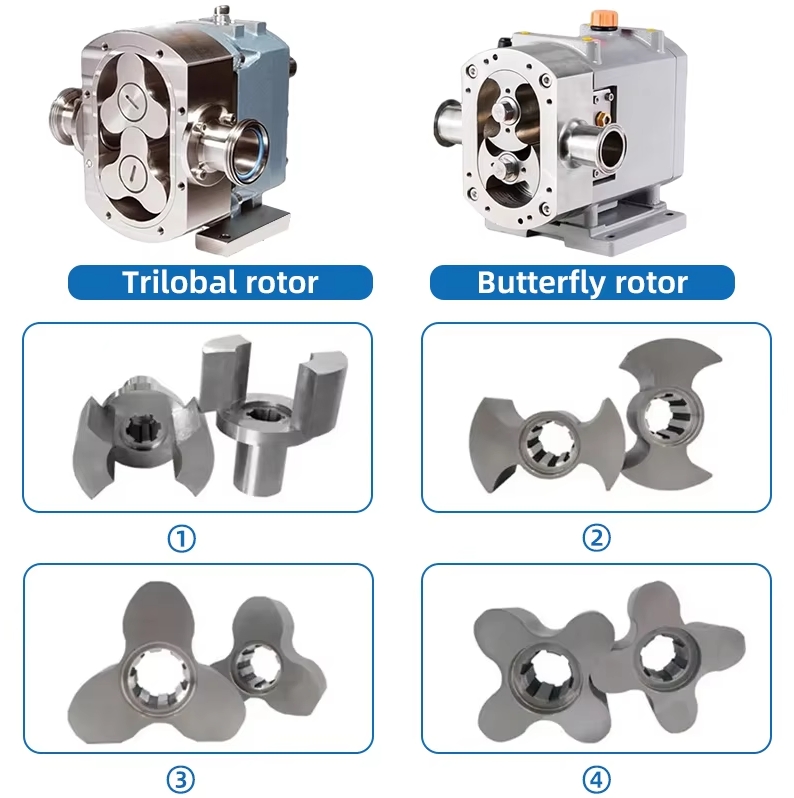

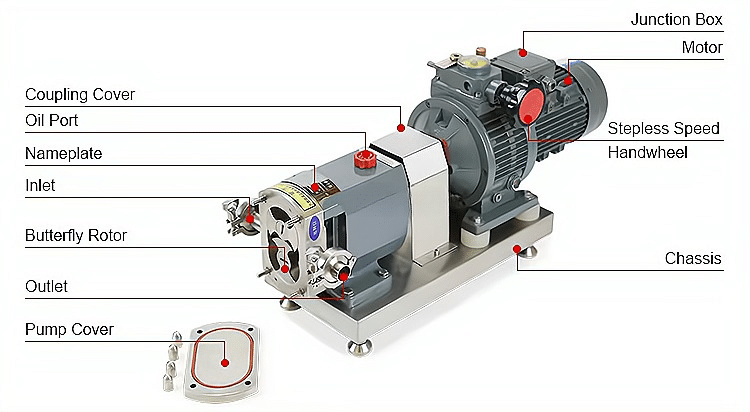

The lobe pump, which is adaptable in the sense that it may contain up to two lobes, three lobes, four lobes or butterfly rotors, as a sanitary volumetric delivery pump comes with benefits such as low-speed operations and high torque output, and also resistance to corrosion and high temperatures. This peculiar working principle and features make it suitable for viscous materials, elevated temperatures, as well as materials that corrode easily. It ensures smooth non-stopping materials transfer while maintaining their physical properties. Moreover, it can move substances of viscosities of 1,000,000 CP without changing them structurally.

Our commitment to quality starts with our team of skilled engineers and technicians who have extensive knowledge and experience in their respective fields. With advanced manufacturing methods and the latest technologies, we produce efficient and durable Lobe pumps on the market today.

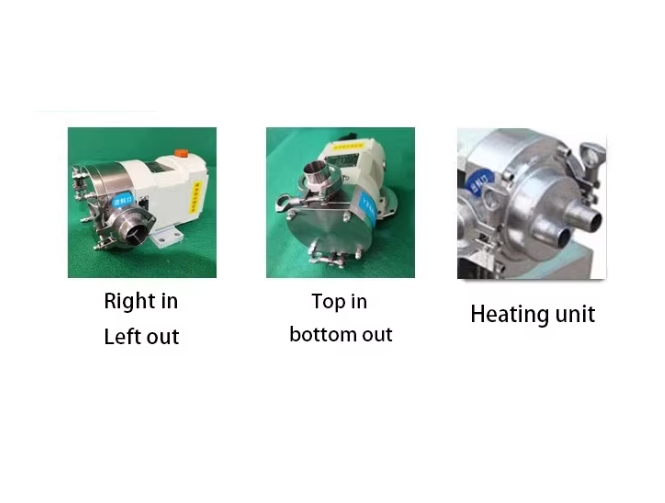

The pump head can be customized to be flat in and flat out, top in and bottom out, with additional insulation. For more pump heads, please contact us for customization.

It can be configured according to customer needs import and export, in the form of: Quick coupling chuck, pagoda joints, flange chucks can be produced.

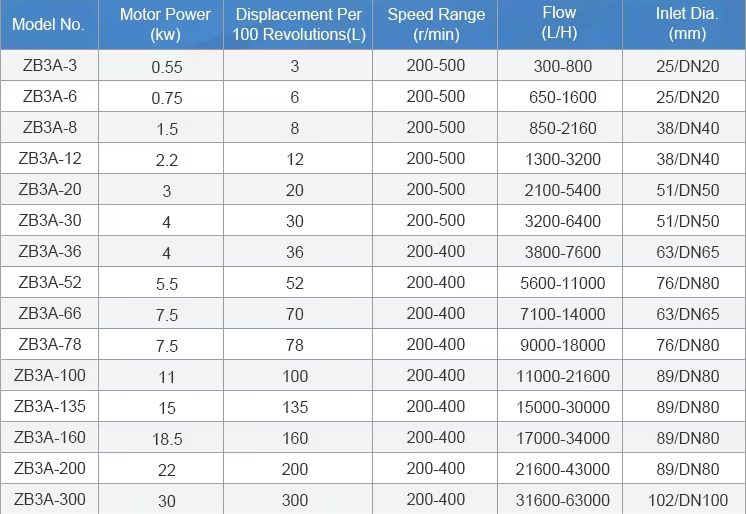

The flow range in the table refers to the data measured when the medium is “water”.It adopts stepless variable speed motor or frequency converter to adjust the speed range from 200 to 900 rpm. When conveying high viscosity concentrated liquid, the motor power must be increased. The data in this form is subject to change without prior notice. The correct parameters are subject to the actual product provided.

Our pumps quality is good, and our price is cheap.

Yes, we are. Welcome to visit our factory.

With the standard products, delivery time will be 7-10 days after we receive your payment.

Any problems happen to our product, we will do our best to help client to solve it, spare parts will be half price in lifetime.

Yes, we very welcome you! More details will be discussed if you are interested.

Usually is T/T, L/C, or Western Union. We also accept Money Gram, PayPal and other payment terms.

We support sea and air transportation, DHL Express, FedEx, UPS delivery.

As a professional supplier

We support customers who want to sell their products through the following channels or distributor

No.545, Jinhai 3rd Avenue, Wenzhou Economic-Technological Development Zone, Wenzhou, Zhejiang, China

Please contact us at:

info@ace-chn.om

+86 18626835909